Molten state lead-free welding flux anti-oxidation reducing agent and preparation process thereof

A lead-free solder, anti-oxidant technology, applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of short continuous use time, decreased insulation resistance, irritating odor, etc., to achieve long continuous use time, line The board surface is clean and the effect of no bad smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] A preparation method of an oxidation-reduction agent for molten lead-free solder comprises the following steps:

[0017] a. Take the above-mentioned various raw materials by weight components.

[0018] b. First put the weighed reducing agent into a stainless steel container, heat until it is completely melted into liquid, and keep the temperature between 100-155°C.

[0019] c. Slowly and uniformly add the weighed antioxidant into the liquid prepared in step b while stirring, the stirring speed is 40-60n / min, and stop heating after stirring at the above temperature for 20-30min.

[0020] d. Continue to stir the material prepared in step c. When the temperature drops to 30-40°C, add a dispersion accelerator while stirring, and then stir for 0.5-1h to obtain the product of the present invention.

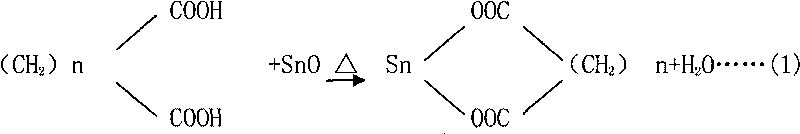

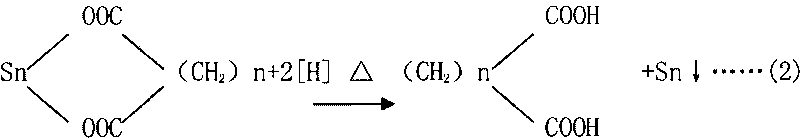

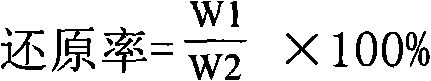

[0021] The oxidation-reduction principle of the present invention is: the melting point of antioxidant, potassium fluoroborate, zinc fluoroborate, tin fluoroborate, potassium fl...

Embodiment 1

[0033] Composition of anti-oxidation reducing agent raw materials: glutaric acid 18kg, potassium fluoroborate 30kg, tin fluoroborate 50kg, triethylenetetramine 2kg.

[0034] Preparation:

[0035] Put the glutaric acid in a stainless steel container and heat it until it completely melts into a liquid, keeping the temperature at 100°C.

[0036] Potassium fluoroborate and tin fluoroborate were slowly and uniformly added to the prepared liquid, stirred at 100° C. for 25 min at a stirring speed of 50 n / min, and then stopped heating.

[0037] Continue to stir the materials prepared above, when the temperature drops to 40°C, add triethylenetetramine, and stir for another 0.5h to obtain the oxidation-reducing agent of the present invention.

Embodiment 2

[0039] Composition of anti-oxidation reducing agent raw materials: suberic acid 2kg, adipic acid 10kg, sebacic acid 14kg, zinc fluorosilicate 31kg, sodium tetraborate 38kg, diethylenetriamine 3kg, triethylenetetramine 2g.

[0040] Preparation:

[0041] Put suberic acid, adipic acid, and sebacic acid in a stainless steel container, heat until they all melt into liquid, and keep the temperature at 155°C.

[0042] Zinc fluoroborate and sodium tetraborate were slowly and uniformly added to the prepared liquid, stirred at 155°C for 30min at a stirring speed of 60 / min, and then stopped heating.

[0043] Continue to stir the above-prepared materials, when the temperature drops to 30°C, add diethylenetriamine and triethylenetetramine, and stir for 1 hour to obtain the oxidation-reducing agent of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com