High speed train damping sound insulation sheet material and manufacturing method thereof

A high-speed train and damping technology, which is applied in railway car body, railway car body parts, film/flake adhesive, etc., can solve the problem that the overall noise in the car cannot be effectively reduced, and the damping material is not suitable for high-speed locomotive damping. Sound insulation, isolation of high-frequency noise and other issues, to achieve good damping and sound insulation effect, large damping factor, and improve the effect of sound insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

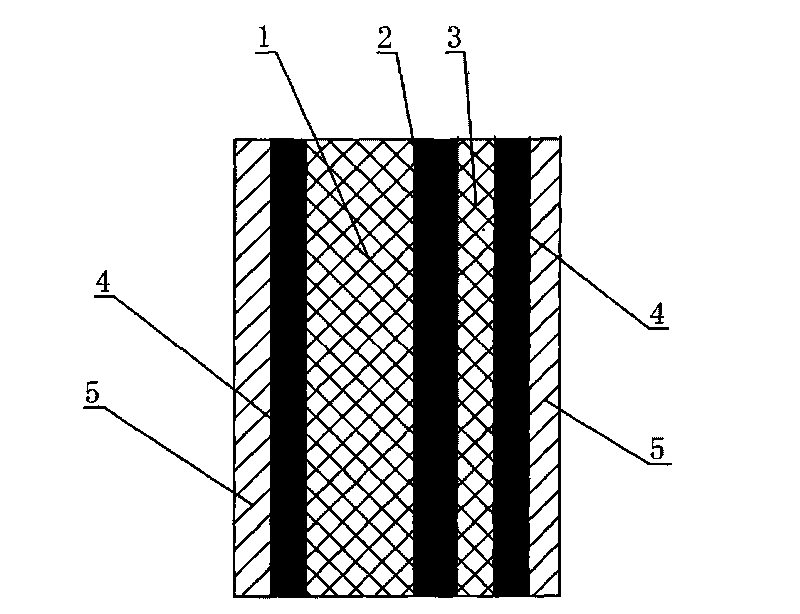

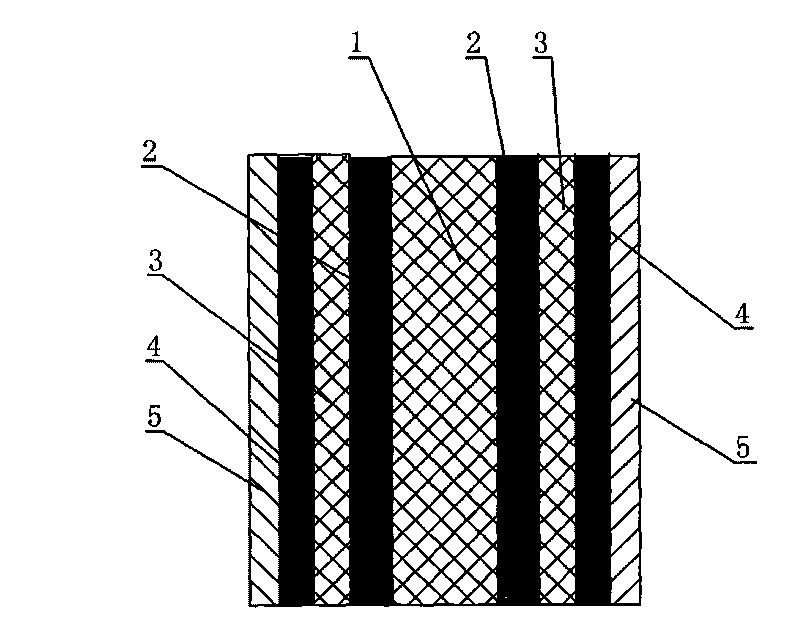

[0079] The high-speed train damping and sound-insulating sheet is composed of a sound-insulating main body damping base layer 1, a damping adhesive layer 2, a resin fiber layer 3, an adhesive layer 4 and a release paper layer 5, and from left to right is the sound-insulating main body Damping base layer 1, damping adhesive glue layer 2, resin fiber layer 3, adhesive layer 4 and release paper layer 5.

[0080] The damping base layer 1 of the sound insulation main body is composed of 7% polyisobutylene rubber, 35% mica, 23% aluminum hydroxide, 20% BaSO 4 , 3% fiber, 1% carbon black, 5% terpene resin, 5% petroleum softener and 1% stearic acid are mixed and processed.

[0081] The damping adhesive layer 2 is formed by mixing 25% acrylic glue, 10% butyl rubber, 30% barium sulfate, 20% aluminum hydroxide and 15% tackifying polybutene resin.

no. 2 example

[0083] The high-speed train damping and sound-insulating sheet is composed of a sound-insulating main body damping base layer 1, a damping adhesive layer 2, a resin fiber layer 3, an adhesive layer 4 and a release paper layer 5, and from left to right is the sound-insulating main body Damping base layer 1, damping adhesive glue layer 2, resin fiber layer 3, adhesive layer 4 and release paper layer 5.

[0084] The damping base layer 1 of the sound-insulating main body is composed of 10% polyisobutylene rubber, 12% mica, 20% aluminum hydroxide, 35% iron powder, 5% fiber, 3% carbon black, and 6% terpene Resin, 6% petroleum softener and 3% stearic acid are mixed and processed.

[0085] The damping adhesive layer 2 is formed by mixing 60% acrylic glue, 5% butyl rubber, 10% barium sulfate, 15% aluminum hydroxide and 10% tackifying polybutene resin.

no. 3 example

[0087] The high-speed train damping and sound-insulating sheet is composed of a sound-insulating main body damping base layer 1, a damping adhesive layer 2, a resin fiber layer 3, an adhesive layer 4 and a release paper layer 5, and from left to right is the sound-insulating main body Damping base layer 1, damping adhesive glue layer 2, resin fiber layer 3, adhesive layer 4 and release paper layer 5.

[0088] The damping base layer 1 of the sound-insulating main body is composed of 20% polyisobutylene rubber, 12% mica, 25% aluminum hydroxide, 22% iron oxide, 4% fiber, 2% carbon black, and 6% terpene Resin, 7% petroleum softener and 2% stearic acid are mixed and processed.

[0089] The damping adhesive layer 2 is formed by mixing 52% acrylic glue, 15% butyl rubber, 20% barium sulfate, 8% aluminum hydroxide and 5% tackifying polybutene resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com