A kind of flame retardant sound insulation composite material and preparation method thereof

A composite material and high damping technology, applied in the field of materials, can solve the problems of flammability, complex preparation process and high VOC concentration, and achieve the effects of improved physical properties, simple process and good reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

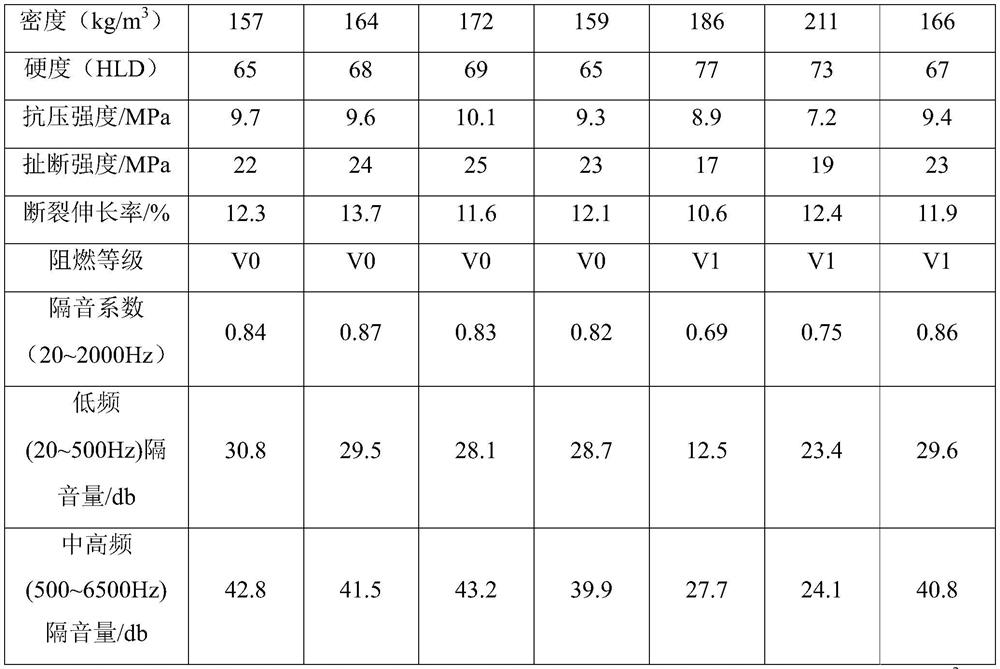

Examples

Embodiment 1

[0030] A flame-retardant and sound-insulating composite material, which is made of the following components in parts by weight: 80 parts of high-damping silicone rubber, 15 parts of silica airgel, 1 part of benzoyl peroxide, 80 parts of ABS resin, 20 parts of white carbon black, 4 parts of hydroxyl silicone oil, 23 parts of foam ceramic powder, 2 parts of light calcium carbonate, 3 parts of zinc borate, 5 parts of high vinyl silicone oil, 0.2 parts of silane coupling agent, and 2 parts of vulcanizing agent.

[0031] A method for preparing a flame-retardant sound-insulating composite material, comprising the following steps:

[0032] Step 1. Weighing: Weigh the components used according to the weight ratio;

[0033] Step 2. Mixing: Add high-damping silicone rubber into the open mill, mix for 2 minutes, slowly add benzoyl peroxide, white carbon black, and hydroxyl silicone oil, and complete the addition in 20 minutes; slowly add silica airgel, foam Ceramic powder, light calcium...

Embodiment 2

[0043] A flame-retardant and sound-insulating composite material, which is made of the following components in parts by weight: 90 parts of high-damping silicone rubber, 18 parts of silica airgel, 1.5 parts of benzoyl peroxide, 90 parts of ABS resin, 25 parts of white carbon black, 5 parts of hydroxyl silicone oil, 31 parts of foam ceramic powder, 3 parts of light calcium carbonate, 5 parts of zinc borate, 6 parts of high vinyl silicone oil, 0.3 parts of silane coupling agent, and 3 parts of vulcanizing agent.

[0044] A method for preparing a flame-retardant sound-insulating composite material, comprising the following steps:

[0045] Step 1. Weighing: Weigh the components used according to the weight ratio;

[0046] Step 2. Mixing: Add high-damping silicone rubber into the open mill, mix for 2.5 minutes, slowly add benzoyl peroxide, white carbon black, and hydroxyl silicone oil, and complete the addition in 25 minutes; slowly add silica airgel, Foam ceramic powder, light ca...

Embodiment 3

[0056] A flame-retardant and sound-insulating composite material, made of the following components in parts by weight: 95 parts of high-damping silicone rubber, 28 parts of silica airgel, 1.8 parts of benzoyl peroxide, 94 parts of ABS resin, 27 parts of white carbon black, 5.5 parts of hydroxyl silicone oil, 35 parts of foam ceramic powder, 3.6 parts of light calcium carbonate, 6 parts of zinc borate, 7 parts of high vinyl silicone oil, 0.35 parts of silane coupling agent, and 4 parts of vulcanizing agent.

[0057] A method for preparing a flame-retardant sound-insulating composite material, comprising the following steps:

[0058] Step 1. Weighing: Weigh the components used according to the weight ratio;

[0059] Step 2. Mixing: Add high-damping silicone rubber into the open mill, mix for 2.8 minutes, slowly add benzoyl peroxide, white carbon black, and hydroxyl silicone oil, and finish adding in 28 minutes; slowly add silica airgel, Foam ceramic powder, light calcium carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength at break | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com