Method for preparing high-thermal-stability cerium-based oxygen storage material

A technology of high thermal stability and oxygen storage materials, applied in separation methods, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as low specific surface area, decreased oxygen storage/release capacity, poor thermal stability of structure and texture, etc. problem, to avoid agglomeration and growth, weaken the interaction force, and reduce the effect of surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

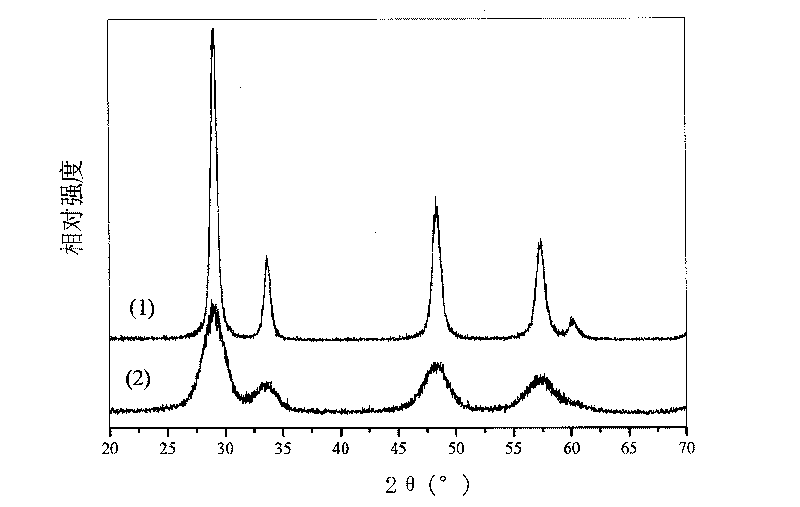

Embodiment 1

[0034] A composite oxide with a composition of 80% of cerium oxide, 10% of zirconia, 5% of aluminum oxide and 5% of lanthanum oxide was prepared. Calculate and weigh the required amount of cerium carbonate, zirconium carbonate and aluminum nitrate according to the composition, put the cerium carbonate, zirconium carbonate and aluminum nitrate in the container, add 65% concentrated nitric acid, and add an appropriate amount of deionized water after completely dissolving , and mixed with hexadecyltrimethylammonium bromide solution (amount of 80% of the total amount of oxides), marked as solution 1. 25 wt% ammonia was diluted and labeled solution 2. Mix solution 1 and solution 2, and adjust the pH value to about 11; then age at 90°C for 48 hours; filter and wash, dry at 110°C in air, and then calcinate at 600°C for 3 hours After that, the specific surface area measured by the BET method is 112m 2 / g, the oxygen storage capacity is 505μmol / g; after calcination at 1050℃ for 5 hou...

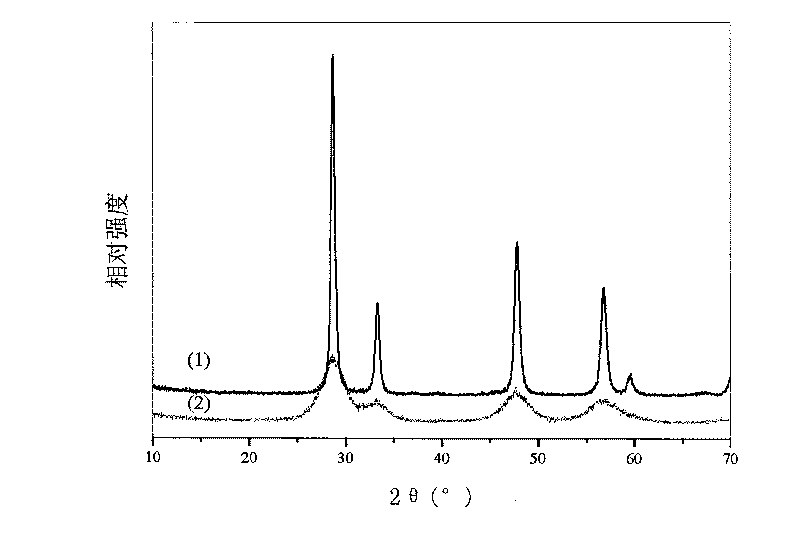

Embodiment 2

[0036] A composite oxide with a composition of 70% cerium oxide, 15% zirconium oxide, 10% aluminum oxide and 5% lanthanum oxide was prepared, and the specific preparation method was the same as that in Example 1 of this part. The difference is that the pH of the reaction is 9, and the aging temperature is room temperature. After calcination at 700°C for 2 hours, the specific surface area of the fresh sample of the obtained cerium-based oxygen storage material is 118m 2 / g, the oxygen storage capacity is 515μmol / g; the specific surface area of the sample after aging is 39m 2 / g, the oxygen storage capacity is 410μmol / g.

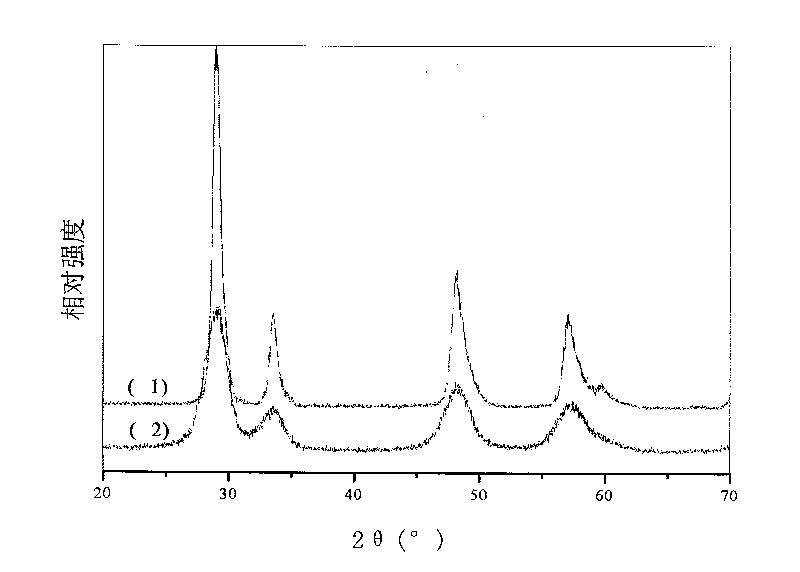

Embodiment 3

[0038] A composite oxide with a composition of 70% cerium oxide, 15% zirconium oxide, 10% aluminum oxide and 5% lanthanum oxide was prepared, and the specific preparation method was the same as that in Example 1 of this part. The difference is that the pH of the reaction is 9, and the aging temperature is room temperature. After calcination at 500°C for 4 hours, the specific surface area of the fresh sample of the obtained cerium-based oxygen storage material is 118m 2 / g, the oxygen storage capacity is 515μmol / g; the specific surface area of the sample after aging is 39m 2 / g, the oxygen storage capacity is 410μmol / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Oxygen storage capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com