Copper, copper/molybdenum, or copper/molybdenum alloy electrode etching solution for use in liquid crystal display system

A technology of molybdenum alloy and etching solution, which is applied in the direction of instruments, circuits, electrical components, etc., can solve the problems of etching process aging changes, explosive pipeline systems, and the stability of etching solution, etc., and achieve excellent etching profile and stable process operation , good flatness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Hereinafter, the present invention will be described in detail with specific embodiments and comparative examples. The explanations described below are used to clearly understand the present invention, and are not intended to limit the scope of the present invention.

[0049] [Example and Comparative Example]

[0050] Prepare the etching solution

[0051] The etching solutions of the first to sixth examples and the first to fourth comparative examples were prepared by mixing the contents and components shown in Table 1 below.

[0052] etching method

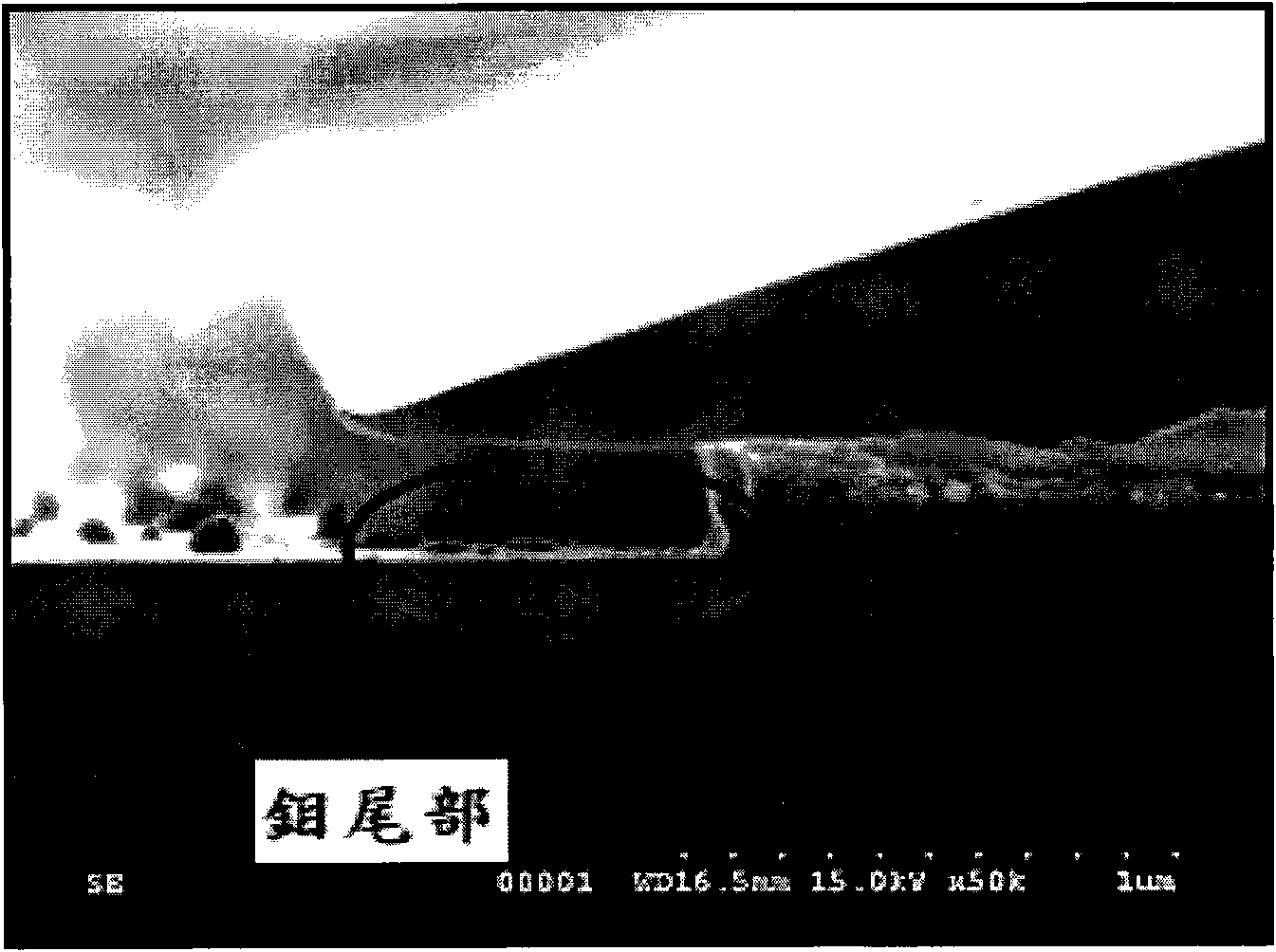

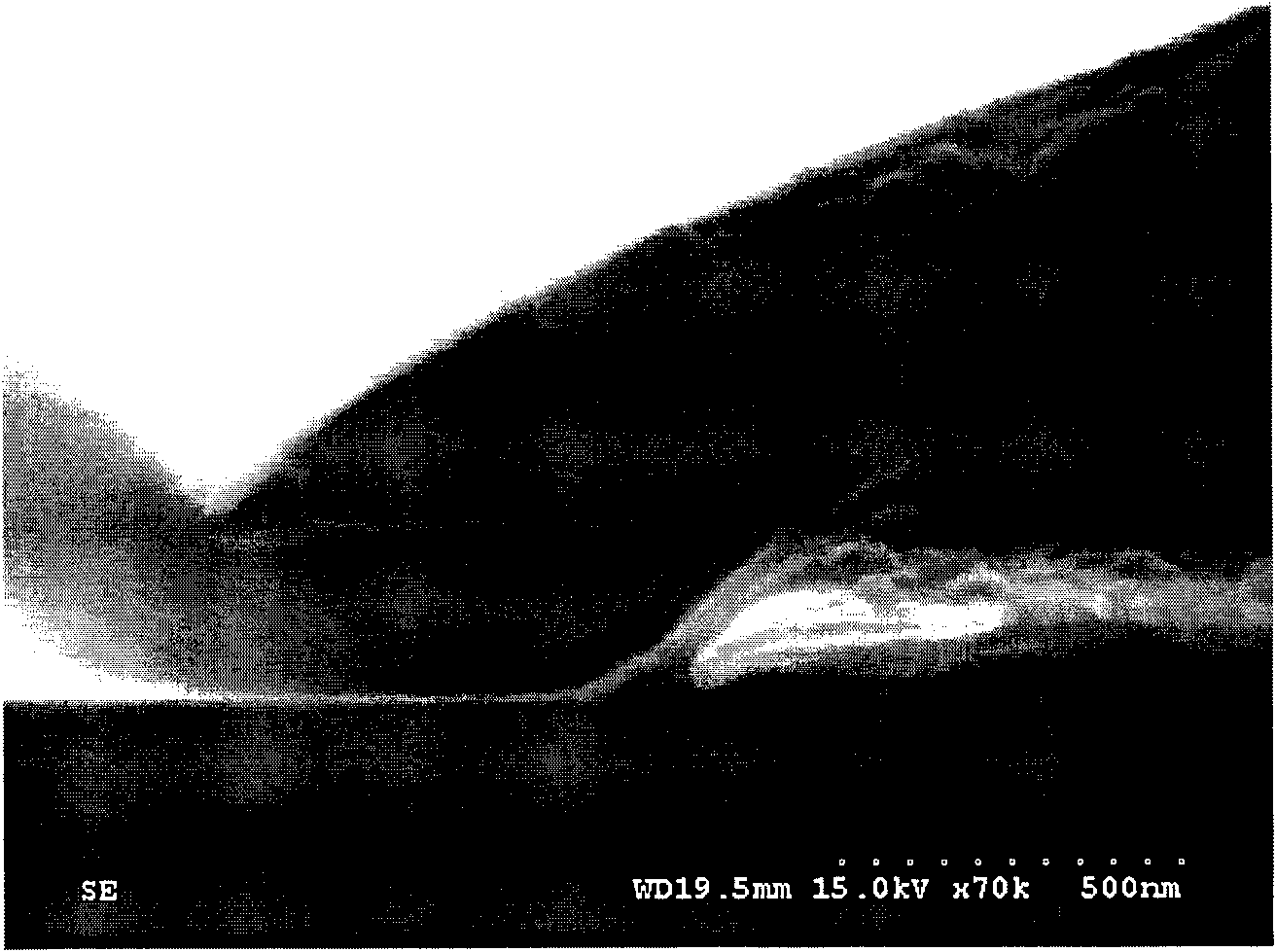

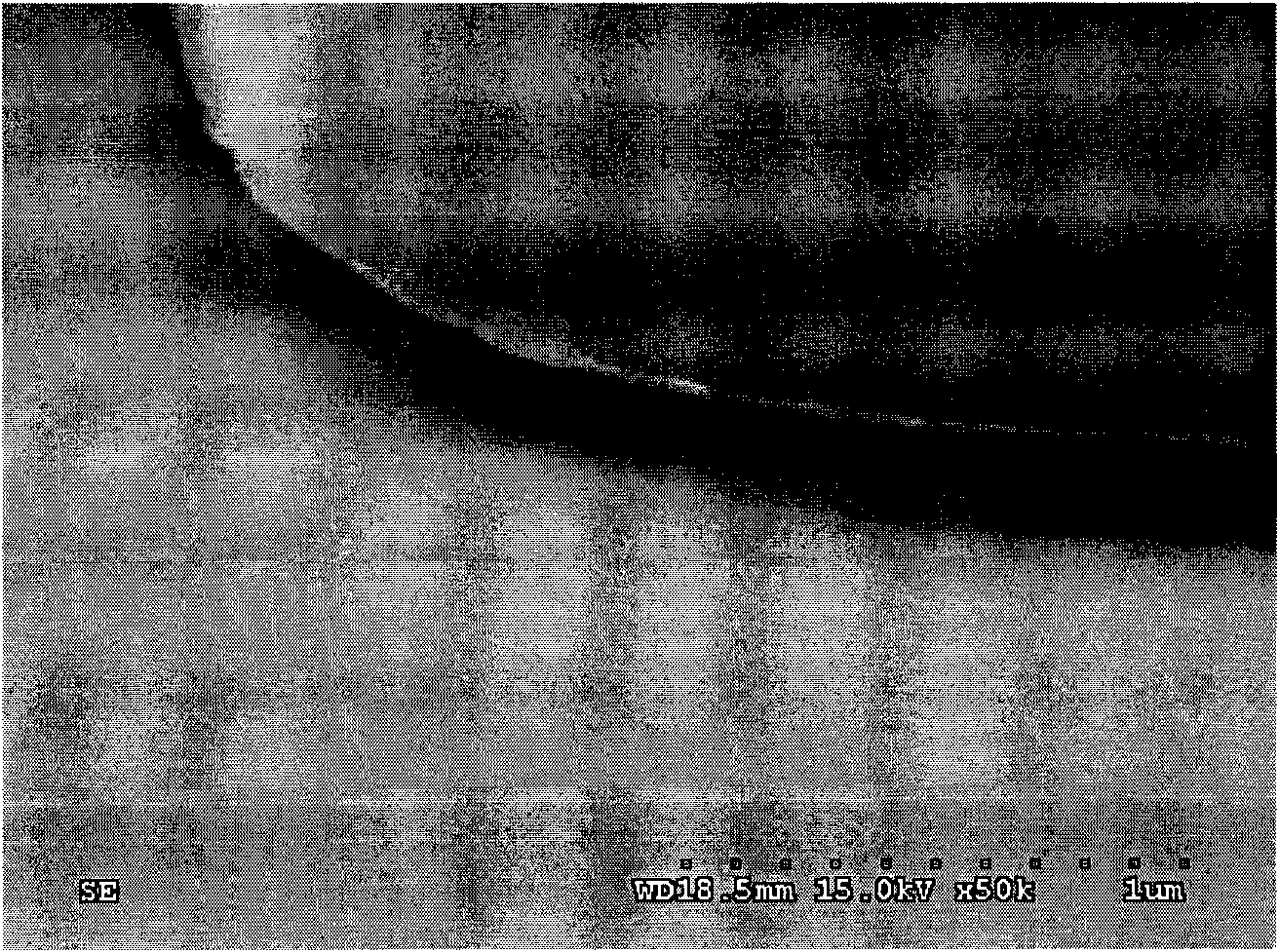

[0053] Depositing a molybdenum layer (200 angstroms) on a glass substrate (100 mm x 100 mm), depositing a copper layer (1600 angstroms) on the molybdenum layer (200 angstroms), and forming a photoresist with a predetermined pattern through a photoresist process on the substrate. Then, an etching process was implemented on the copper / molybdenum double layer using the etching solutions of Examples 1-6 and Comparative Exa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com