A kind of preparation method of tungsten-copper-silver composite powder

A composite powder and tungsten-copper technology, which is applied in liquid chemical plating, coating, metal material coating process, etc., can solve the problems of many processes, low product impurities, high cost, etc., and achieve tight bonding and uniformity of the coating , the effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

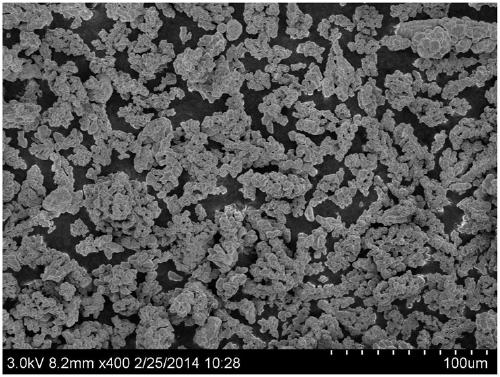

Image

Examples

Embodiment 1

[0028] A preparation method of tungsten-copper-silver composite powder, comprising the steps of:

[0029] 1) Take 1 kg of tungsten powder and add it to 250 ml of wetting agent ethanol and soak for 1 hour, then rinse with deionized water after taking it out;

[0030] 2) Then add tungsten powder into the copper plating solution with a volume of 40L. The content of each substance in the copper plating solution is: copper nitrate 10g / L, EDTA 25g / L, use NaOH to adjust the pH of the copper plating solution to 11-12 , control the temperature at 60°C and stir for 10 minutes, then rinse with deionized water, and use a centrifuge to separate the copper-plated tungsten powder;

[0031] 3) Add 120 mL of formaldehyde solution and 10 kg of deionized water to the copper-coated tungsten powder obtained above, and stir mechanically at a high speed to disperse the copper-coated tungsten powder evenly;

[0032] 4) Under stirring conditions, add 220g of trisodium citrate into 1000ml of aqueous s...

Embodiment 2

[0035] A preparation method of tungsten-copper-silver composite powder, comprising the steps of:

[0036] 1) Take 1 kg of tungsten powder and add it to 130 ml of wetting agent isopropanol and soak for 1 hour, then rinse with deionized water after taking it out;

[0037] 2) Then add tungsten powder into the copper plating solution with a volume of 40L. The content of each substance in the copper plating solution is: copper chloride 10g / L, EDTA 10g / L, use NaOH to adjust the pH of the copper plating solution to 11~ 12. Control the temperature at 50°C and stir for 15 minutes, then rinse with deionized water, and use a centrifuge to separate the copper-plated tungsten powder;

[0038] 3) Add 120 g of potassium sodium tartrate and 10 kg of deionized water to the copper-plated tungsten powder obtained above, and stir mechanically at a high speed to disperse the copper-plated tungsten powder evenly;

[0039] 4) Under agitation, add 850 g of triethanolamine into 1000 ml of aqueous sol...

Embodiment 3

[0042] A preparation method of tungsten-copper-silver composite powder, comprising the steps of:

[0043] 1) Take 1 kg of tungsten powder and add it to 1250 ml of wetting agent acetone and soak for 1 hour, then rinse with deionized water after taking it out;

[0044] 2) Then tungsten powder is added to the copper plating solution with a volume of 40L. The content of each substance in the copper plating solution is: copper sulfate 10g / L, trisodium citrate 15g / L, and NaOH is used to adjust the pH of the copper plating solution to 12-14, control the temperature at 60°C and stir for 20 minutes, then rinse with deionized water, and use a centrifuge to separate the copper-plated tungsten powder;

[0045] 3) Add 200 g of hydrazine sulfate and 10 Kg of deionized water to the copper-plated tungsten powder obtained above, and stir mechanically at a high speed to disperse the copper-plated tungsten powder evenly;

[0046] 4) Under stirring conditions, add 240g of trisodium citrate and 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com