Method of producing surface acoustic wave devices by exposing X-rays

A surface acoustic wave device and X-ray technology, applied in the direction of electrical components, impedance networks, etc., can solve the problems of low work efficiency and high cost, achieve the effects of reducing production cost, improving working frequency and performance, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0046] The invention adopts X-ray photolithography technology, which is an effective nano-processing method and has nano-level resolution. The present invention mainly utilizes electron beam lithography to prepare a master plate for X-ray exposure, and then uses X-ray exposure to form an electronic resist concave vertical electrode pattern of an interdigital transducer with a spacing of less than 500 nm on a piezoelectric substrate, and then grows Surface acoustic wave devices can be prepared by interdigital transducer electrode metal and peeling off.

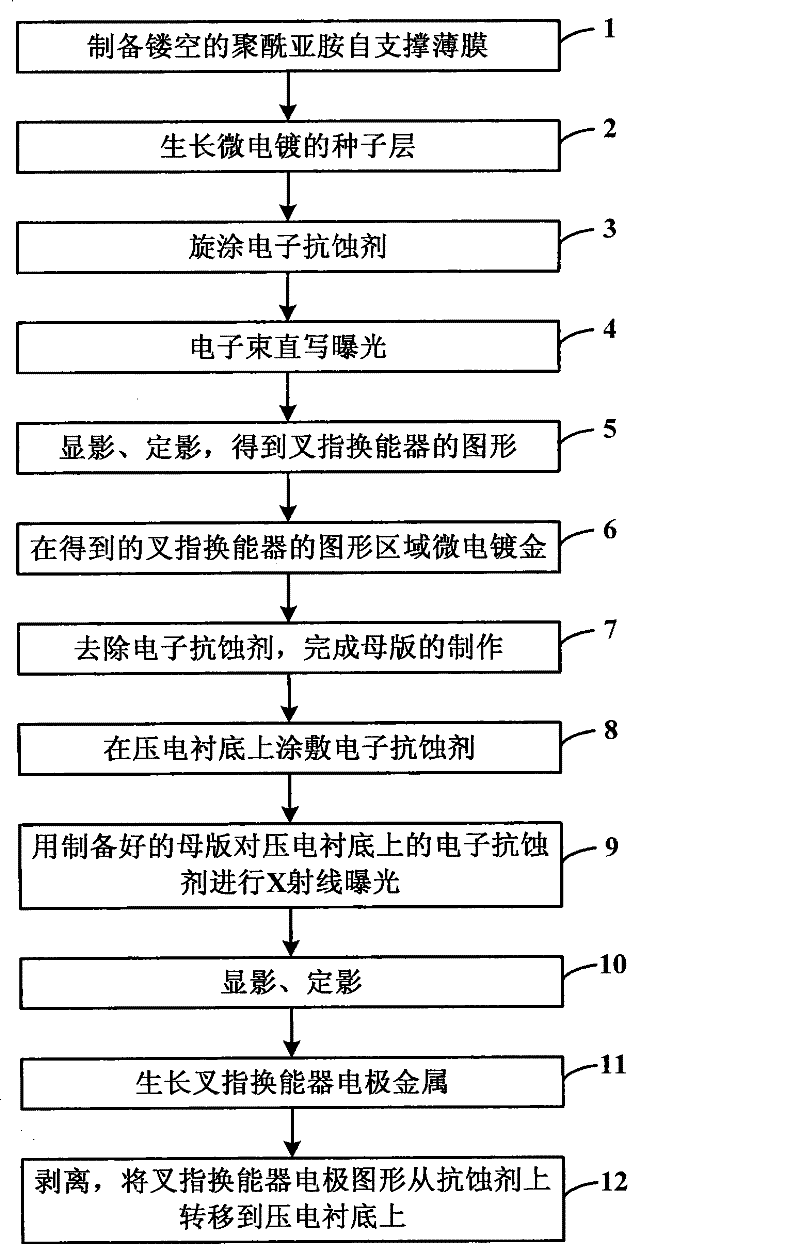

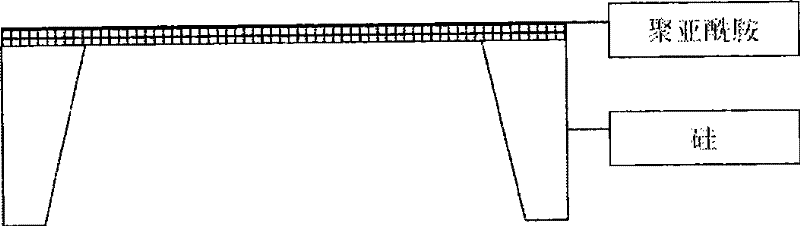

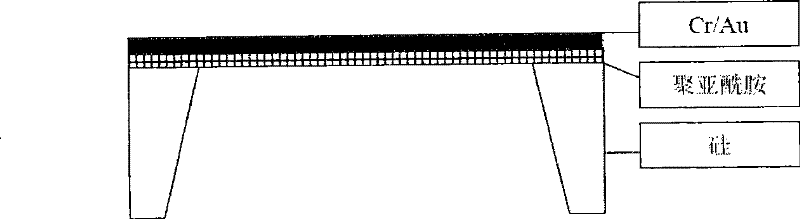

[0047] Such as figure 1 as shown, figure 1 It is a flowchart of a method for fabricating a surface acoustic wave device by X-ray exposure provided by the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com