Manufacturing method of small-aperture polyether sulfone planar film for membrane bioreactor

A membrane bioreactor and manufacturing method technology, applied in the field of polyethersulfone membranes, can solve the problems of easy pore blockage of flux, difficult pore blockage, sharp reduction, etc., and achieve the effects of strong anti-pollution ability, small pore size and high flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

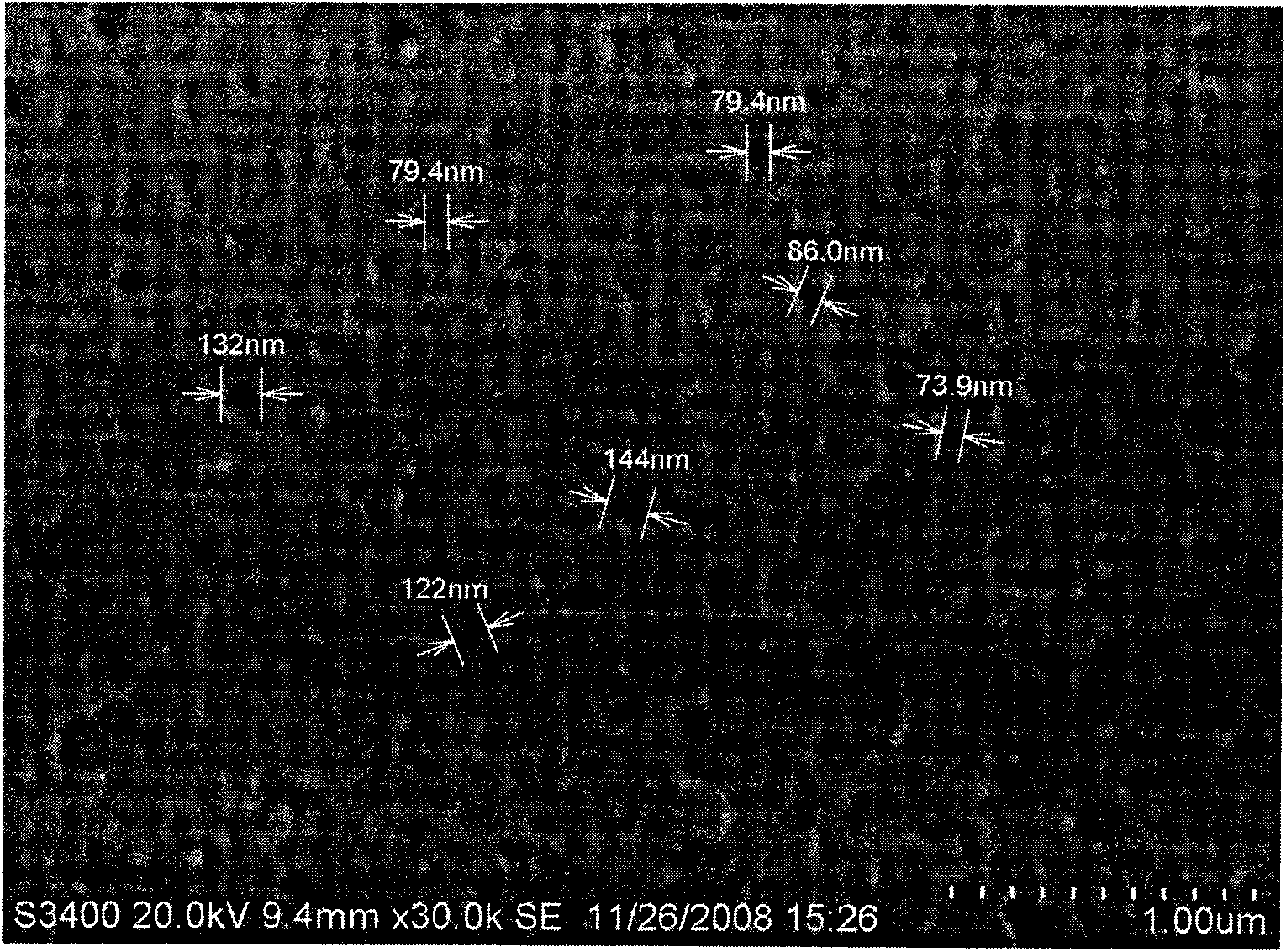

[0042] According to the following components and composition batching: polyethersulfone 13%, DMF (N, N dimethylformamide) 56%, polyethylene glycol (4000) 16%, polyethylene glycol (20000) 10%, PVP ( polyvinylpyrrolidone) 4%, surfactant 1.0%. The above raw materials were mixed to prepare a casting solution, heated at 80°C, and dissolved for a week. After the gained casting solution is filtered, cast on the polyester non-woven fabric (density 100g / m 2 , thickness 0.15mm), adjust the gap between the blades of the film-making machine to 0.35mm, the film-forming speed to 2.5 m / min, the relative humidity of the air in the film-making room to be 50%, and the temperature of the coagulation bath to form a film under the conditions of 17-18°C. After the prepared membrane is washed with water, pore-preserved and dried, a flat polyethersulfone filter membrane is obtained (see Figure 1 ). Figure 1 , two This is the electron microscope photo of the surface and section of the membrane....

Embodiment 2

[0044] According to the following components and ingredients: polyethersulfone 16%, NMP (N-methylpyrrolidone 54%, polyethylene glycol (1000) 13%, PEG (20000) 12.5%, PVP (polyvinylpyrrolidone) 4%, Surfactant 0.5%. The above raw materials are mixed to prepare casting solution, heated at 80°C, and dissolved for one week. N 2Air pressure filtration. After the gained casting solution is degassed, cast on the polyester non-woven fabric (density 95g / m 2 , thickness 0.2mm), adjust the gap between the blades of the film-making machine to 0.30mm, the film-forming speed to 2.5 m / min, the relative air humidity in the film-making room to be 55%, and the coagulation bath temperature to be continuously formed under the conditions of 20-21°C. The prepared film is washed with water, treated with pore preservation and dried to obtain a finished film.

[0045] Figure three This is the surface electron microscope photo of the finished membrane in this example. The photo shows that the surface...

Embodiment 3

[0047] The finished film of above-mentioned embodiment 1 is made into 5 pieces of small flat membrane module (size 8 * 22cm), and effective membrane area is about 1400cm 2 , immersed in the activated sludge tank, the liquid level height is 80cm, the activated sludge concentration is 6000mg / L, and the aeration intensity is 0.2m 3 / h, influent COD=400~500mg / L, BOD=200~300mg / L, the effluent water quality of the planar membrane module is as follows:

[0048]

[0049] The permeate flux is initially 32L / m 2 h, After 27 days of operation, the water production flux decreased by about 15% due to the deposition of surface pollutants. After mechanical washing of the membrane surface, the water production flux recovered to the original level, showing the excellent anti-pollution ability of the small pore membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com