Barium strontium titanate ceramic capacitor material and preparation method thereof

A technology of ceramic capacitors and barium strontium titanate, which is applied in the field of ceramic capacitor materials and its preparation, can solve the problems of coarse grains, reduced breakdown strength, and high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) First select the analytically pure chemical reagent BaCO 3 , SrCO 3 And TiO 2 , Press Ba 0.4 Sr 0.6 TiO 3 Ingredients, ball milled for 24h, dried, calcined at 1150℃ for 4h to form Ba 0.4 Sr 0.6 TiO 3 powder.

[0030] (2) According to the components in Table 2, after fully mixing, melting at 1100°C for 1 hour, quickly pour the glass liquid into cold water for quenching to obtain glass fragments, then ball mill the glass fragments for 4 hours and pass through a 400 mesh sieve to obtain glass powder A.

[0031] Table 2 Composition of glass powder A

[0032]

[0033] (3) According to 98vol% Ba 0.4 Sr 0.6 TiO 3 +2vol% glass powder A with ethanol as the dispersant, using agate balls, ball milling for 24 hours, and drying in an oven at 90°C to obtain a powder.

[0034] (4) The powder prepared in step (3) was subjected to cold isostatic pressing at a pressing pressure of 200Mpa to form a sample with a diameter of 20mm and a thickness of 2mm, and sintered at 1150°C for 1h in an air ...

Embodiment 2

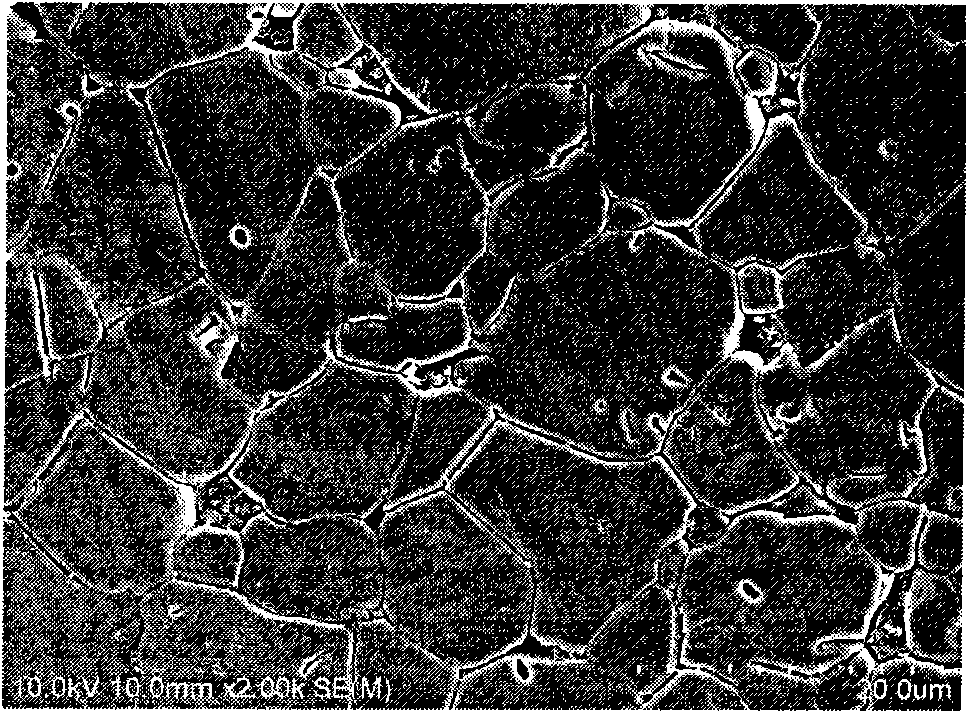

[0040] According to 95vol% Ba 0.4 Sr 0.6 TiO 3 +5vol% glass powder A ratio, the specific process route is the same as in Example 2. The microscopic morphology of the components described in this example is as image 3 As shown, by adding 5 vol% glass powder A, the grain size of the sample is further refined, and the average grain size is 2 μm. The dielectric properties are shown in Table 4.

[0041] Table 4 Dielectric properties of the components described in Example 2

[0042]

Embodiment 3

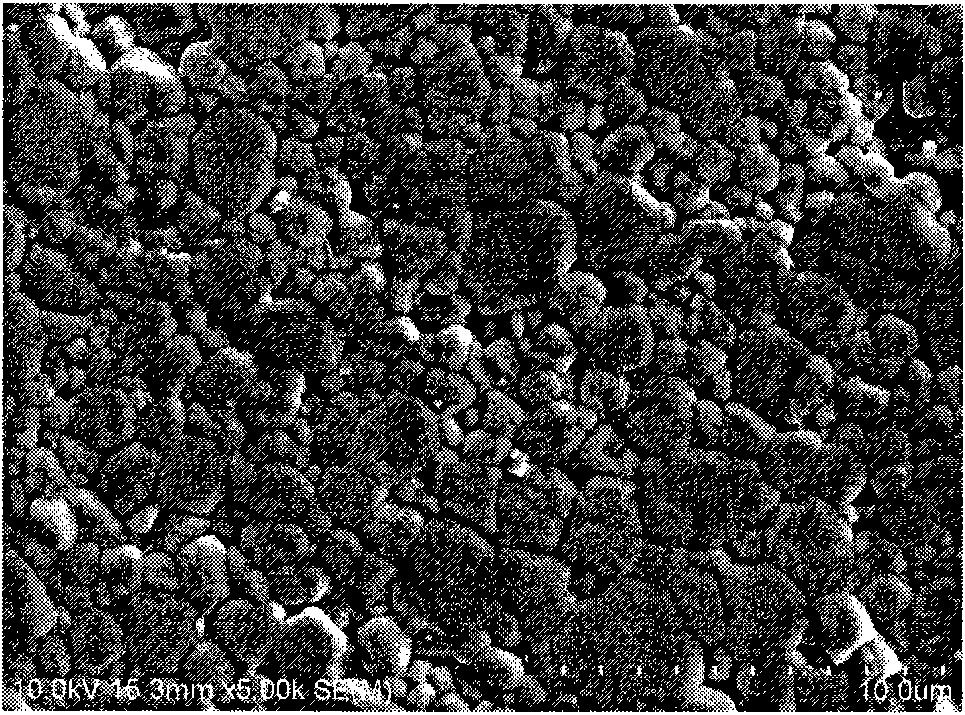

[0044] According to 90vol% Ba 0.4 Sr 0.6 TiO 3 +10vol% glass powder A, the specific process route is the same as in Example 2. The microscopic morphology of the components described in this example is as Figure 4 As shown, adding 10 vol% glass powder A, the average crystal grain size of the sample is 1.5 μm. The dielectric properties are shown in Table 5.

[0045] Table 5 Dielectric properties of the components described in Example 3

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com