Technology for extracting copper powder from waste materials generated in circuit board manufacturing plants by compound extraction method

A technology of circuit boards and production plants, applied in the fields of comprehensive utilization, environmental protection, and electronic product recycling, to achieve the effect of saving investment and improving the right to speak

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

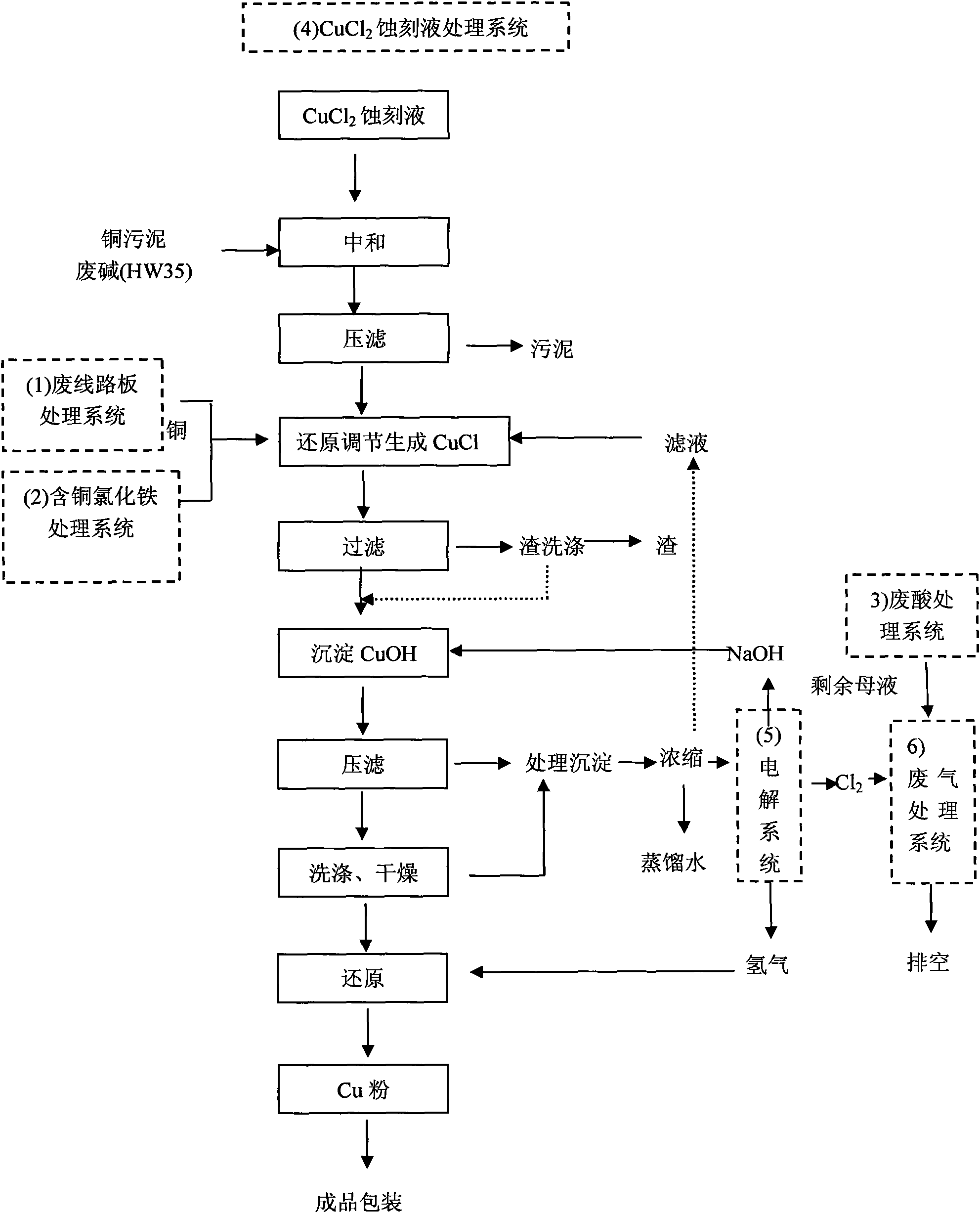

Image

Examples

Embodiment 1

[0043] February 12, 2008

[0044] Raw materials: 1 ton of waste circuit boards; 5 tons of copper chloride etching solution with 10% copper content; 0.2 tons of copper sludge; 0.65 tons of waste alkali; 1 ton of copper and ferric chloride with 4% copper content; 1 waste acid Ton.

[0045] Circuit board processing system: After 1 ton of waste circuit boards are crushed, stripped and sorted, 0.2 tons of copper material is obtained, which enters the etching solution processing system; 0.8 tons of resin is outsourced for disposal and utilization.

[0046] Copper-containing ferric chloride treatment system: 1 ton of copper-containing ferric chloride solution with a copper concentration of about 4%. After adding 62kg of iron powder, 53.1kg of sponge copper (purity 75%) is obtained, which enters the etching solution processing system; the remaining mother liquor Enter the exhaust gas treatment system.

[0047] Waste acid treatment system: 1 ton of waste acid, 33kg iron oxide scale is added, ...

Embodiment 2

[0051] August 27, 2008

[0052] Raw materials: 1 ton of waste circuit boards; 5 tons of copper chloride etching solution with 11% copper content; 0.3 tons of copper sludge; 0.70 tons of waste alkali; 1 ton of copper ferric chloride with 4% copper content; 1 waste acid Ton.

[0053] Circuit board processing system: After 1 ton of waste circuit boards are crushed, stripped and sorted, 0.2 tons of copper material is obtained, which enters the etching solution processing system; 0.8 tons of resin is outsourced for disposal and utilization.

[0054] Copper-containing ferric chloride treatment system: 1 ton of copper-containing ferric chloride solution with a copper concentration of about 4%. After adding 65kg of iron powder, 55kg of sponge copper (purity 75%) is obtained, which enters the etching solution processing system; the remaining mother liquor enters Exhaust gas treatment system.

[0055] Waste acid treatment system: 1 ton of waste acid, 35kg iron oxide scale is added, and the fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com