Aquatic amino acid preparation and preparation method and aquatic feed thereof

A technology of aquatic feed and amino acid, applied in animal feed, animal feed, application, etc., can solve problems such as full utilization of nutrients without special consideration, too fast dissolution time, and exposure of stuffing, so as to achieve small environmental impact on aquaculture water and reduce interaction , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

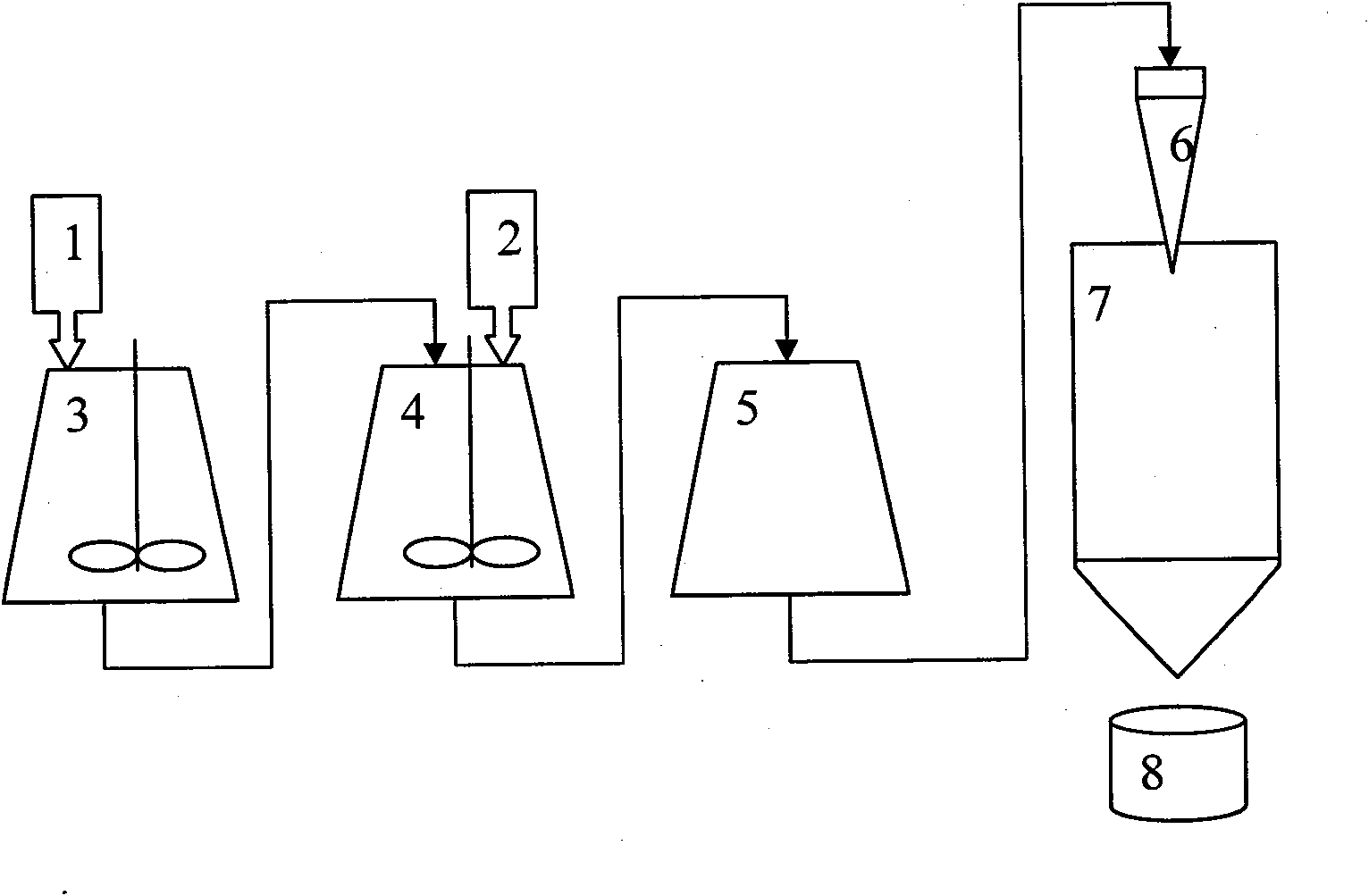

Method used

Image

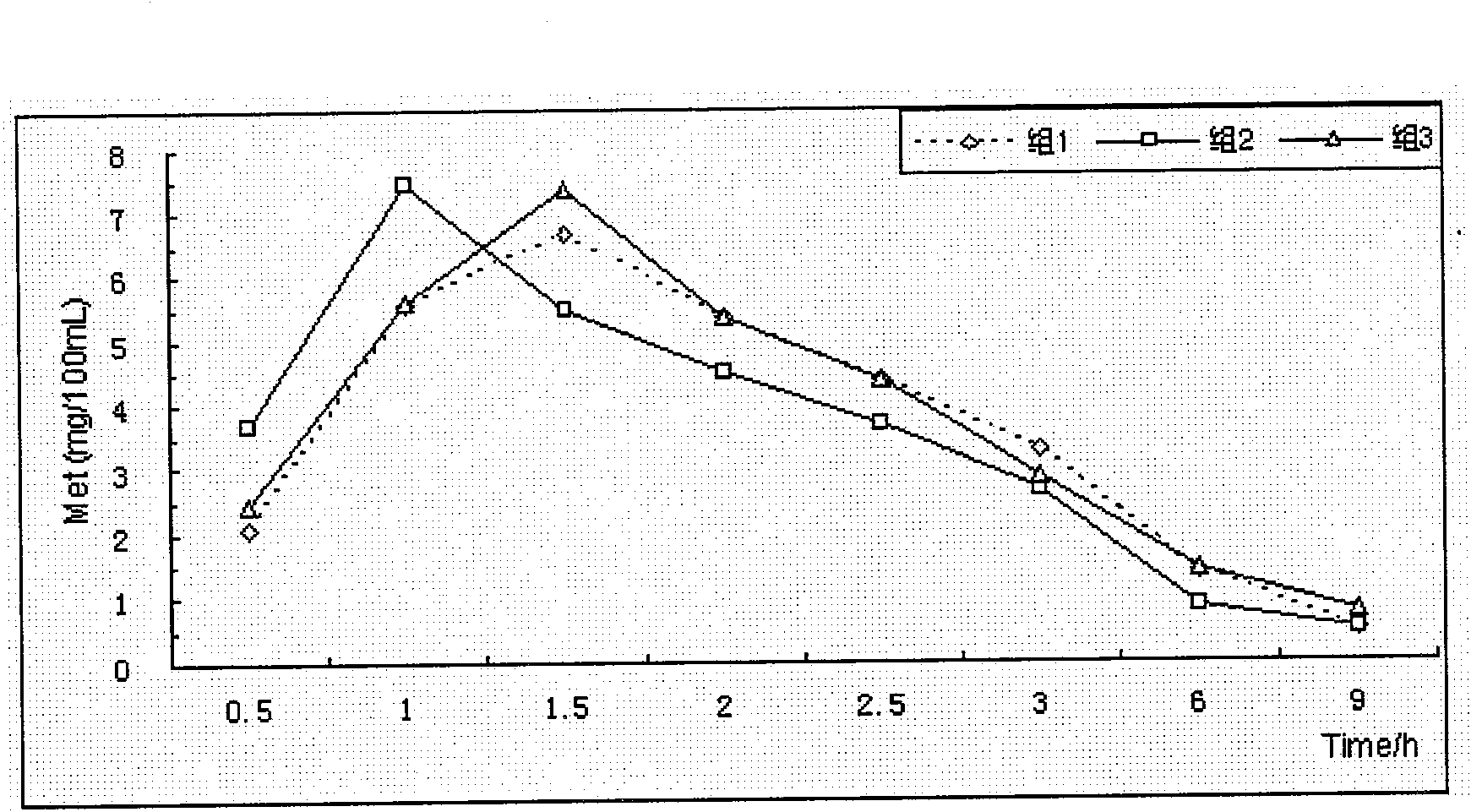

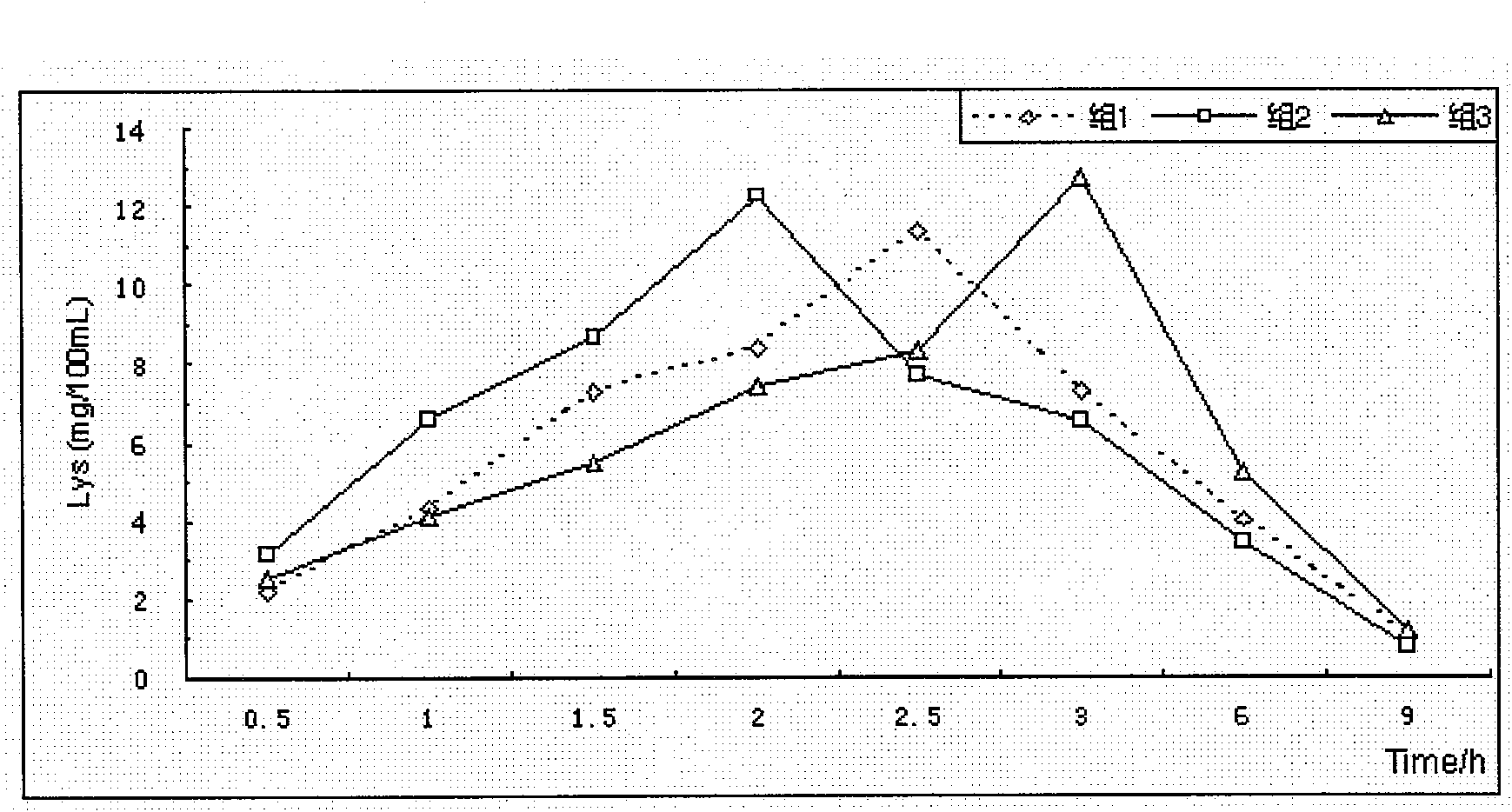

Examples

Embodiment 1

[0066] Select 225kg of stearic acid and put it into the chemical material tank, heat it to 80°C, stir continuously, and wait for it to melt completely; Put 230kg of hydrochloride into the batching tank, shear and stir for 10 minutes, during which the temperature should be controlled at 80°C; import the uniformly mixed material into the storage tank, and heat the temperature to 80-100°C; start the feeding spray device, and put the storage The materials in the feed tank are granulated by spraying; the finished product particles are collected by sieving with a 24-80 mesh vibrating sieve. Finally, 448 kg of finished lysine microcapsule preparations were obtained, with a particle size of 200-700 μm and a yield of 98.4%.

[0067] Replace the above-mentioned lysine raw material with essential amino acid raw materials such as methionine, threonine, tryptophan, repeat the above steps, the results are basically the same.

Embodiment 2

[0069] Select 175kg (1:1) of stearic acid and fat powder into the chemical material tank, heat to 80°C, stir continuously, and wait for it to completely melt; pump the melted stearic acid and fat powder from the chemical material tank into the batching tank, and simultaneously 180kg of accurately weighed L-lysine hydrochloride (purity 99%) is dropped into the batching tank, sheared and stirred for 8 minutes, during which the temperature will be controlled at 80°C; the uniformly mixed material will be introduced into the storage tank, and Heat the temperature to 80-100°C; start the feeding and spraying device, and granulate the prepared materials in the storage tank through spray freezing equipment; sieve and collect the finished product granules with a 24-80 mesh vibrating sieve. Finally, 348 kg of finished lysine microcapsule preparations were obtained, the particle size was 200-700 μm, and the yield could reach 99%.

[0070] Replace the above-mentioned lysine raw material wi...

Embodiment 3

[0072] Select 100kg of stearic acid and put it into the chemical material tank, heat and stir until the stearic acid is completely melted, then put in 50 kg of crushed paraffin, pump the evenly melted capsule material auxiliary materials from the chemical material tank into the batching tank, start the batching tank shear Switch off the pump, and at the same time, slowly add 100kg of feed grade DL-methionine raw material into the batching tank, shear and stir for 8-10 minutes, so that the methionine raw material, stearic acid, and paraffin mixture are melted evenly; then the uniformly mixed material is introduced into the storage tank , and heat the temperature to 80-90°C; start the feeding and spraying device, and granulate the materials in the storage tank through the spray freezing equipment; sieve and collect the finished product granules with a 30-80 mesh vibrating sieve. The weight content of methionine in the finally obtained finished methionine microcapsule preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com