Follower component driven by driving mechanism in pressure shell and water reactor adopting same

A driving mechanism and water-squeezing rod technology, which is applied in the field of nuclear reactor engineering technology, to achieve the effects of increasing conversion ratio, saving uranium resources, and reducing fuel cycle costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

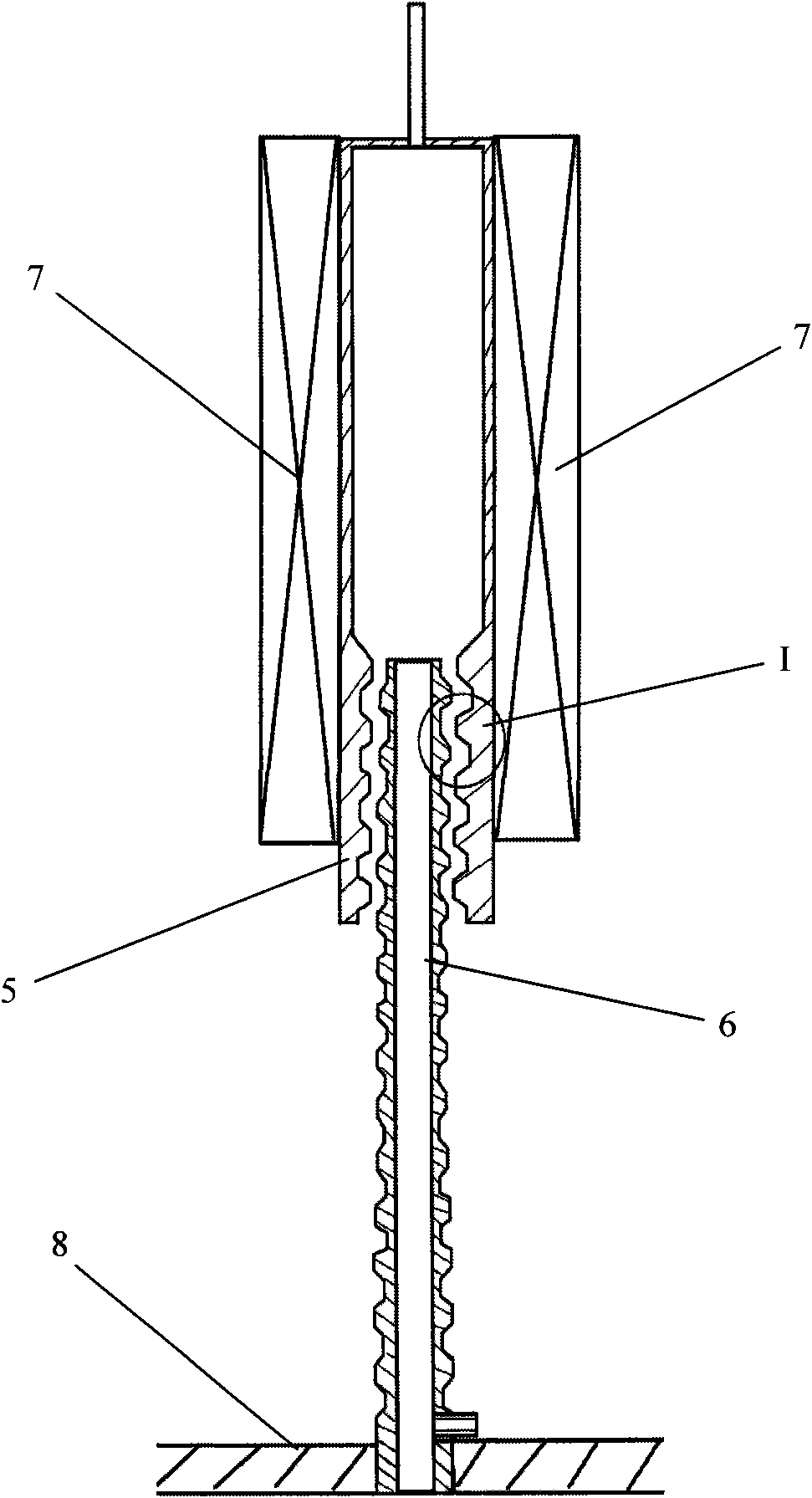

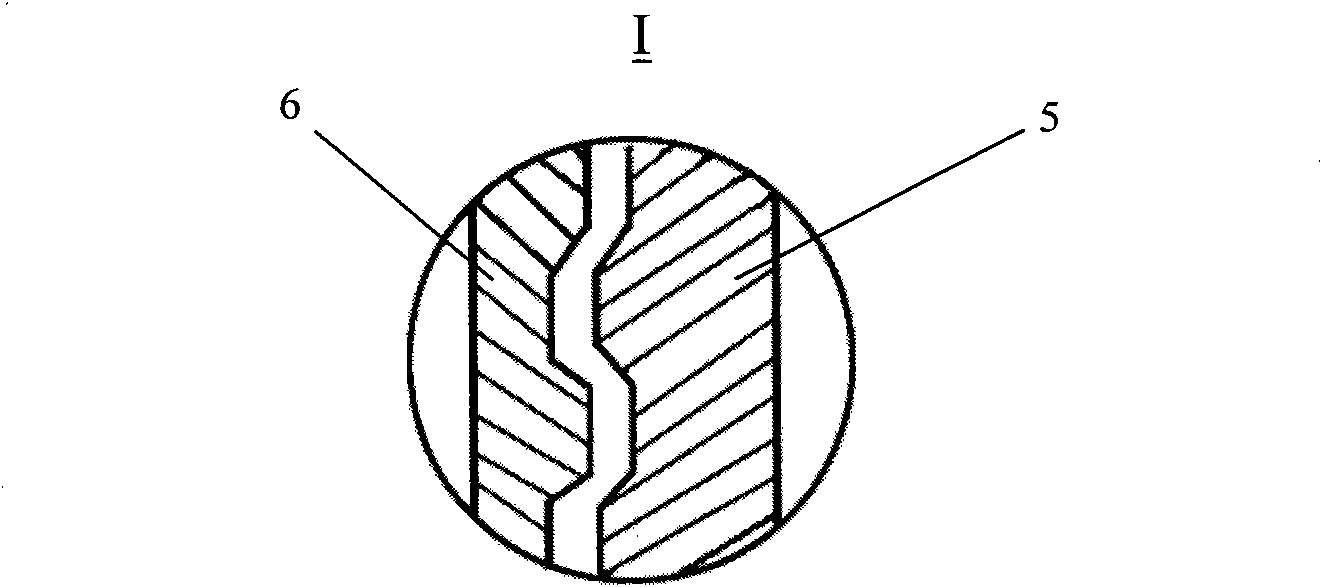

[0037] In the pressure shell of a 1000Mwe pressurized water reactor, water-squeezing rod bundles with zirconium alloy cladding on the outside and depleted uranium dioxide core inside are installed in the hexagonal bundle fuel assembly of the core and on the six corner points And the cross-section is Y-shaped water squeezing rods, which are respectively connected to the dynamic cylinder of the built-in hydraulic drive mechanism in the pressure shell, and the static cylinder is fixed on the guide tube support plate, and the depleted uranium dioxide is squeezed out of the water rod at the beginning of the fuel cycle Insert the fuel assembly into the core, and extract it step by step during the burnup process. By changing the average water-uranium ratio of the core, the reactivity spectrum shift control of the reactor can be realized, thereby greatly reducing the boron concentration in the primary circuit water of the PWR during operation. (It is only necessary to increase the conc...

Embodiment 2

[0042]In the pressure shell of a 1000Mwe pressurized water reactor that has been in operation, a cross-shaped water squeeze rod assembly driven by a hydraulic drive mechanism is installed at the four corners of the core square rod bundle fuel assembly. The water squeeze rod is composed of zirconium cladding and its inner Composed of depleted uranium dioxide core body, the reactivity spectrum shift control of the reactor is realized, and at the same time, the original solid control rod assembly and its electromagnetic drive mechanism are retained. The core is composed of 157 square fuel assemblies of 21.45cm×21.45cm, with a grid pitch of 1.26cm, 289 (17×17) rod positions, and fuel assemblies with control rods, including 264 fuel rods, 1 measuring tube, and 24 Each of the Zr-4 control rod conduits occupies the position of one fuel rod, and the cross-section is set at the four corners of the fuel assembly as a cross-shaped water squeeze rod assembly. The thickness of the water squ...

Embodiment 3

[0045] In a supercritical water nuclear reactor with a net electric power of 100Mwe (thermal power of 250Mwt) using sleeved fuel assemblies (the structure of a supercritical water nuclear reactor using sleeved fuel assemblies can be found in Chinese Patent 200510055365.5), a low-carbon ferrite pressure vessel with an inner diameter of 245cm The inner wall is surfacing with stainless steel cladding, the wall thickness is 20.0cm, it can withstand the design pressure of 27.5Mpa, the operating pressure of supercritical water is 25Mpa, the equivalent diameter of the active area of the core is 133cm, and the core has 19 casing fuel assemblies arranged in a triangle , the structure of the casing fuel assembly is as follows Figure 9 As shown, it includes a coaxial Zr-2.5% Nb outer casing 21, an alloy material (stainless steel, nickel-based alloy or aluminum-based niobium-containing alloy and other materials) middle casing 22 and center tube 23, the outer radius of the outer casing i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com