Method for separating grinding material layer and basal body of electroplated diamond grinding head

A technology of electroplating diamond and separation method, which is applied in the field of separating the abrasive layer and the substrate of electroplating diamond grinding head, can solve the problems of strong corrosion, low recovery efficiency, long time, etc., and achieve precise heating depth, precise heating temperature, surface oxidation less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

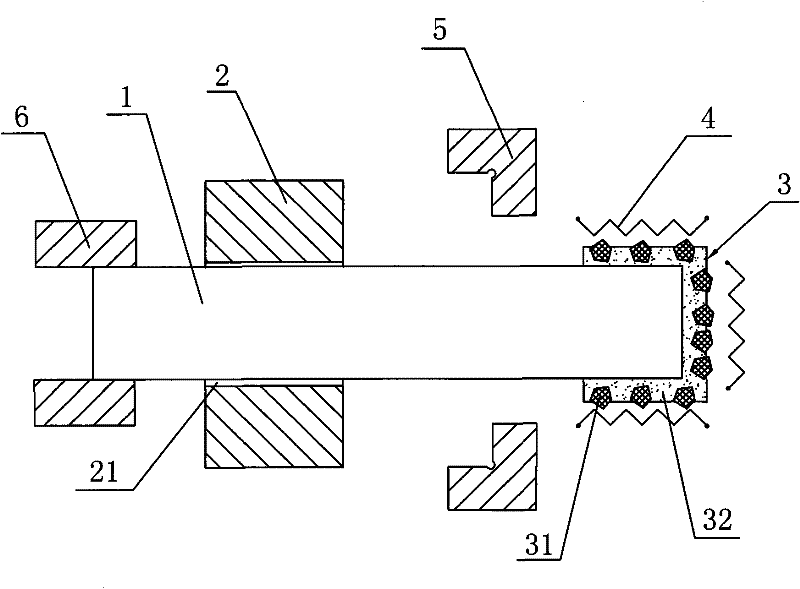

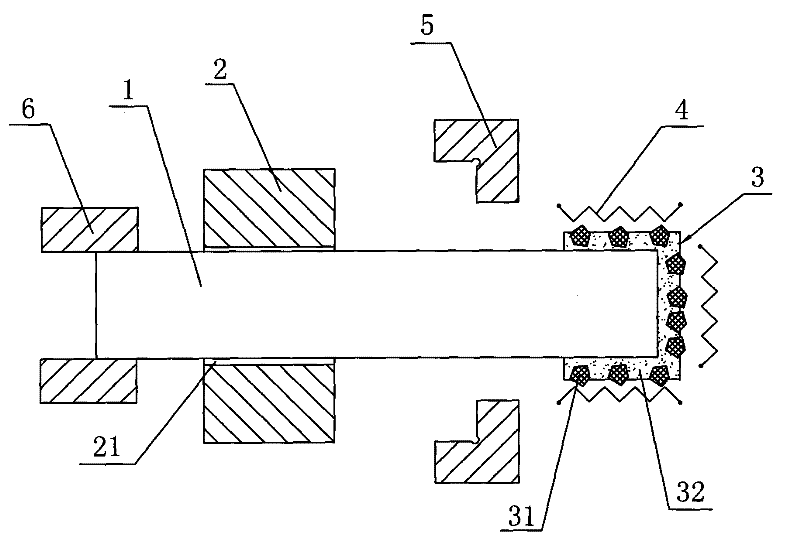

[0018] Embodiment one: a kind of separation method of electroplated diamond grinding head abrasive layer and matrix, it comprises the following steps:

[0019] (1), place the first fixture 6, the bracket 2, the induction coil 4 on the second fixture 5 and the induction heater (not shown in the figure) in order, and fix the bracket 2, the second fixture 5 and the induction coil 4. Adjust the size of the through hole 21 on the bracket 2 at the same time, so that the diameter of the through hole 21 is smaller than the outer diameter of the grinding head abrasive layer 3 and slightly larger than the diameter of the grinding head base 1;

[0020] (2), get substrate 1 to be No. 35 steel, plated metal 32 is nickel, the particle size number of diamond abrasive grain 31 is the diamond grinding head to be recovered of 120 / 140, the abrasive material layer 3 of diamond grinding head is suspended and stretched into induction coil 4 Keep a gap of 1.5mm between it and the induction coil 4, t...

Embodiment 2

[0025] Embodiment two: a kind of separation method of electroplated diamond grinding head abrasive layer and matrix, it comprises the following steps:

[0026] (1), place the first fixture 6, the bracket 2, the induction coil 4 on the second fixture 5 and the induction heater (not shown in the figure) in order, and fix the bracket 2, the second fixture 5 and the induction coil 4. Adjust the size of the through hole 21 on the bracket 2 at the same time, so that the diameter of the through hole 21 is smaller than the outer diameter of the grinding head abrasive layer 3 and slightly larger than the diameter of the grinding head base 1;

[0027] (2), get substrate 1 to be No. 35 steel, plated metal 32 is nickel, the particle size number of diamond abrasive grain 31 is the diamond grinding head to be recovered of 120 / 140, the abrasive material layer 3 of diamond grinding head is suspended and stretched into induction coil 4 Keep a gap of 2mm between it and the induction coil 4, the...

Embodiment 3

[0032] Embodiment three: a kind of separation method of electroplated diamond grinding head abrasive layer and matrix, it comprises the following steps:

[0033] (1), place the first fixture 6, the bracket 2, the induction coil 4 on the second fixture 5 and the induction heater (not shown in the figure) in order, and fix the bracket 2, the second fixture 5 and the induction coil 4. Adjust the size of the through hole 21 on the bracket 2 at the same time, so that the diameter of the through hole 21 is smaller than the outer diameter of the grinding head abrasive layer 3 and slightly larger than the diameter of the grinding head base 1;

[0034] (2), get substrate 1 to be No. 35 steel, plated metal 32 is nickel, the particle size number of diamond abrasive grain 31 is the diamond grinding head to be recovered of 120 / 140, the abrasive material layer 3 of diamond grinding head is suspended and stretched into induction coil 4 , keep a gap of 3 mm between it and the induction coil 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com