Silver-copper-rare earth composite material

A composite material and rare earth technology, which is applied in current collectors, electrical components, rotating current collectors, etc., can solve the problems of wear resistance and service life reduction, segregation of silver-copper alloys, and unstable contact resistance, etc., to achieve service life long, suppress temperature rise, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

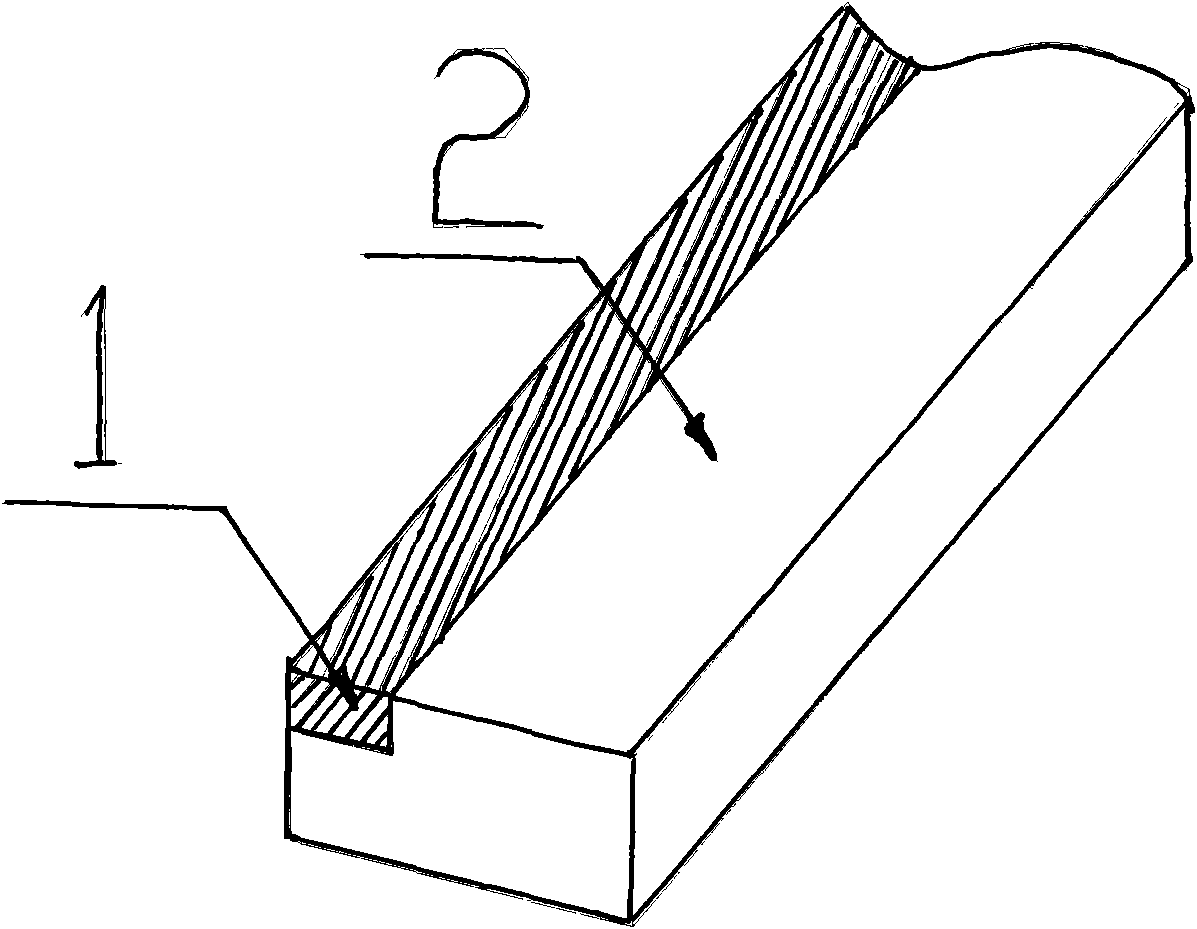

[0013] like figure 1 , the present invention comprises a copper layer, a silver alloy layer embedded and compounded on the copper layer, characterized in that the silver alloy layer contains 3-8% Cu, 0.2-0.8% Sn, 0.2-0.8% Ce, and the balance is Ag silver alloy. The silver alloy layer (1) is embedded and compounded on part of the surface of the copper layer (2).

[0014] Preparation method is: will contain 6.00% Cu, 0.50% Sn, 0.50% Ce, the balance is Ag's silver alloy strip material (as embodiment 1 in table 1) is embedded on the copper alloy strip material and cut out its thickness The AgCuSnCe / Cu composite material was prepared by using room temperature rolling composite four-step process in a groove with a moderate width, that is, surface treatment-rolling composite-diffusion annealing-precision rolling.

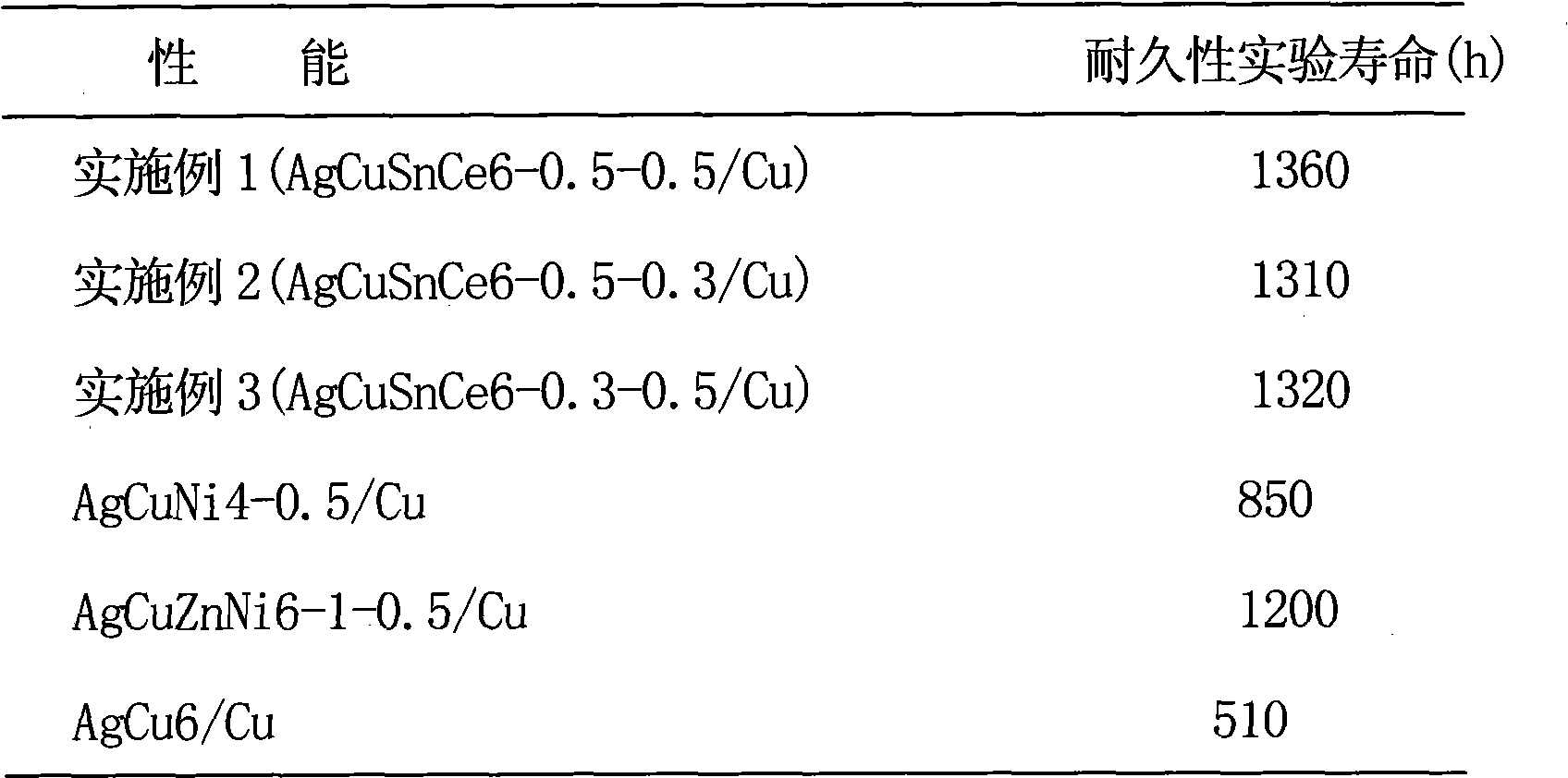

[0015] The AgCuSnCe / Cu composite material of the present invention is paired with the AgPd30 / Cu brush material and assembled on the micro-motor, and the durability test ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com