Rolling contact rotary electrical connector

A rolling contact, internal conduction technology, applied in the direction of rotating current collectors, circuits, connections, etc., can solve problems such as increased wear, power supply short-circuit failure, affecting service life, etc., to achieve long working life, reduce friction and wear, and good electrical contact performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

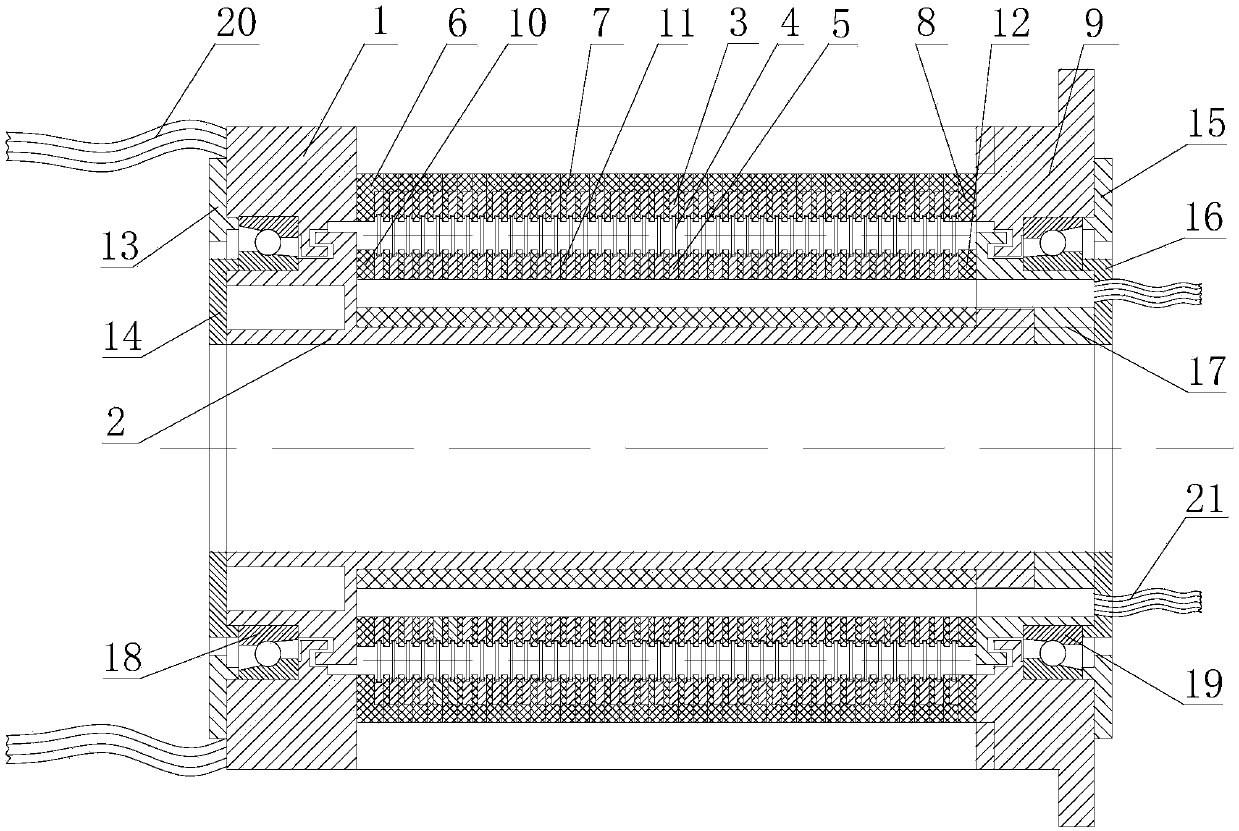

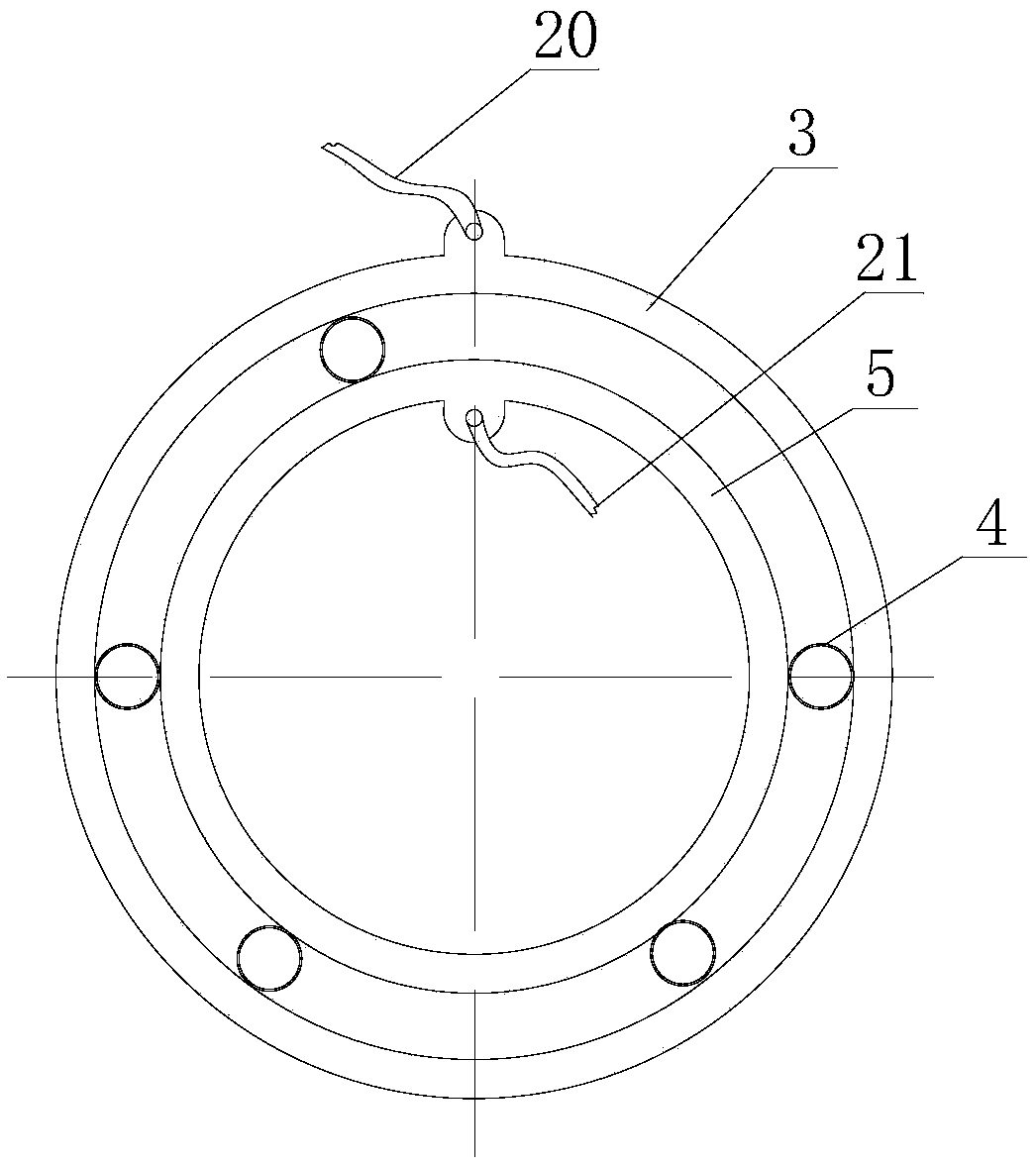

[0018] The following will combine Figure 1 ~ Figure 3 The rolling contact rotary electrical connector of the present invention is further described in detail.

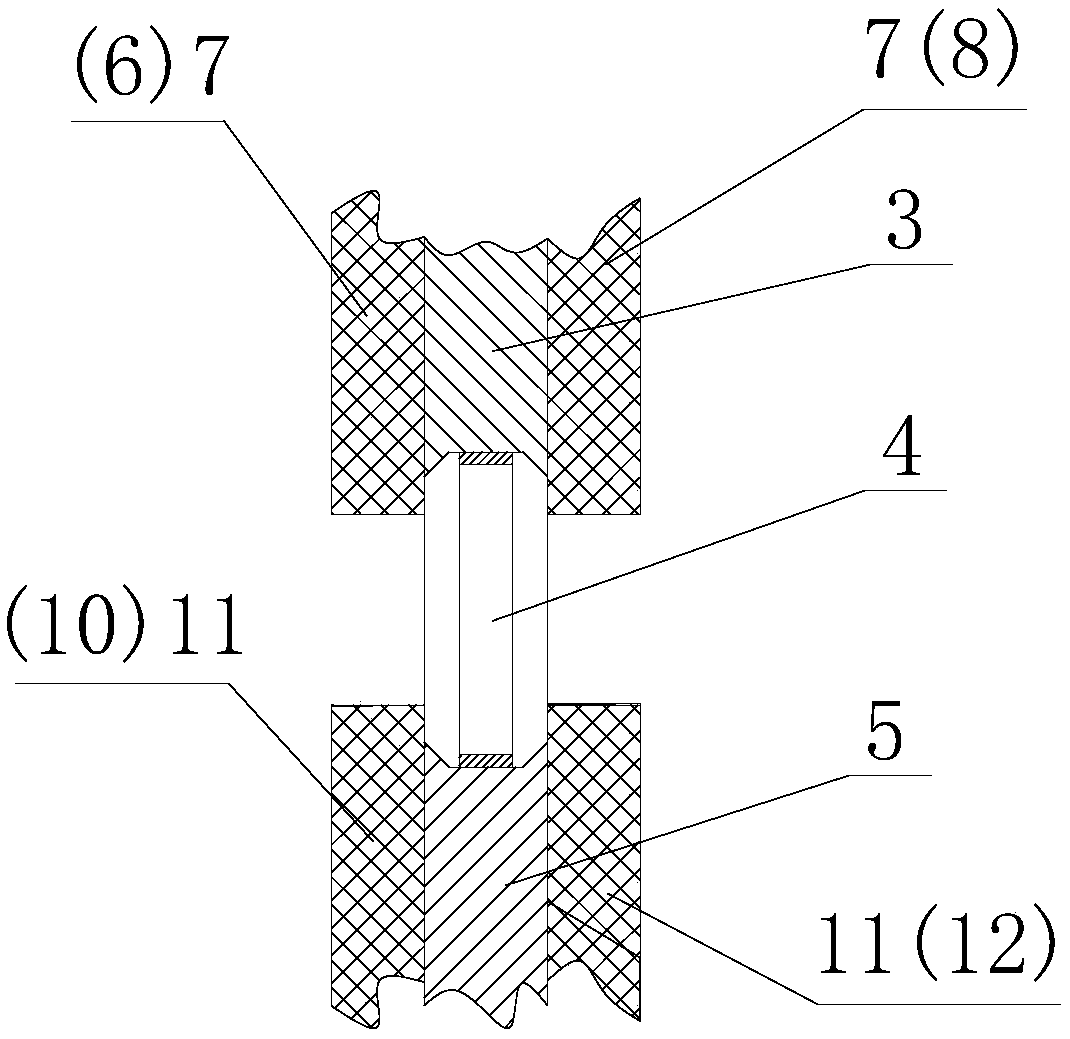

[0019] figure 1 Shown is a schematic cross-sectional view of the structure of the rolling contact rotary electrical connector; the outer conductive ring 3 is set on the housing 1, and the insulation between the outer conductive ring 3 and the housing 1 is realized through the insulating rings 6, 7, 8, and each outer conductive ring For mutual insulation, the outer conductive ring, the insulating ring and the shell are connected as a whole through the flange 9 .

[0020] The inner conductive ring 5 is sleeved on the shaft 2, the insulation between the inner conductive ring 5 and the shaft 2 and the mutual insulation between the inner conductive rings are realized through the insulating rings 10, 11, 12, and the inner conductive ring, the insulating ring and the The shaft is connected as a whole. The flexible ring 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com