Soft support cantilever beam type silicon micro-piezoelectric microphone chip and preparation method thereof

A cantilever beam, electro-microphone technology with applications in the fabrication/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, material selection for piezoelectric or electrostrictive devices Equal direction, can solve the problem of low microphone sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

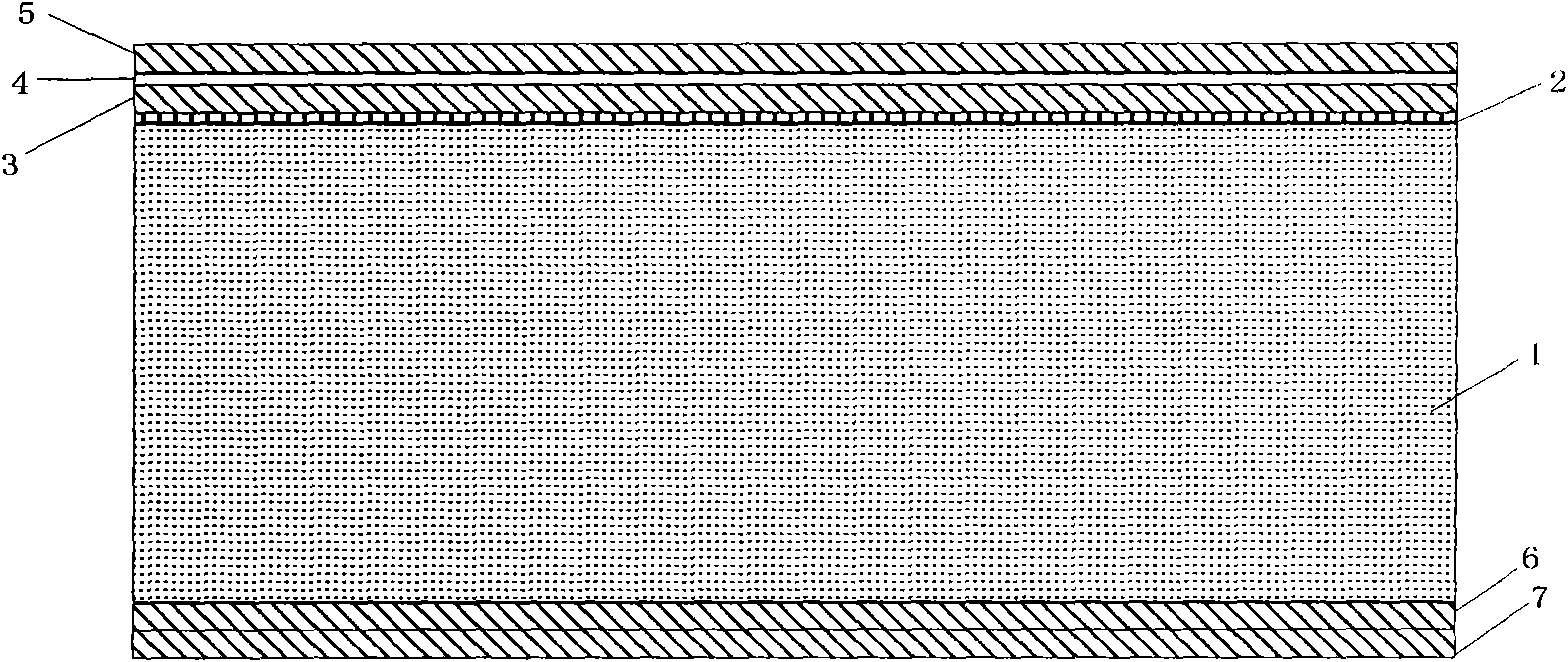

[0068] Embodiment 1, adopt preparation method of the present invention to prepare a piezoelectric microphone chip, its steps are as follows:

[0069] 1) Clean the silicon substrate 1

[0070] Cleaning the silicon substrate 1 with an acid cleaning solution and an alkaline cleaning solution respectively, and then rinsing it with deionized water;

[0071] 2) Oxide layer formation by thermal oxidation 2

[0072] On the silicon substrate 1, use a thermal oxidation furnace to oxidize the oxide layer with a thickness of 0.2 μm, and remove the oxide layer on the reverse side, so that a thermal oxide film layer 2 with a thickness of 0.2 μm is formed on the front side of the substrate 1;

[0073] 3) Low-pressure chemical vapor deposition of the first silicon nitride film layer 3

[0074] A first silicon nitride film layer 3 with a thickness of 0.5 μm on the thermal oxide film layer 2 and a third silicon nitride mask layer 6 with a thickness of 0.5 μm on the reverse side of the silicon...

Embodiment 2

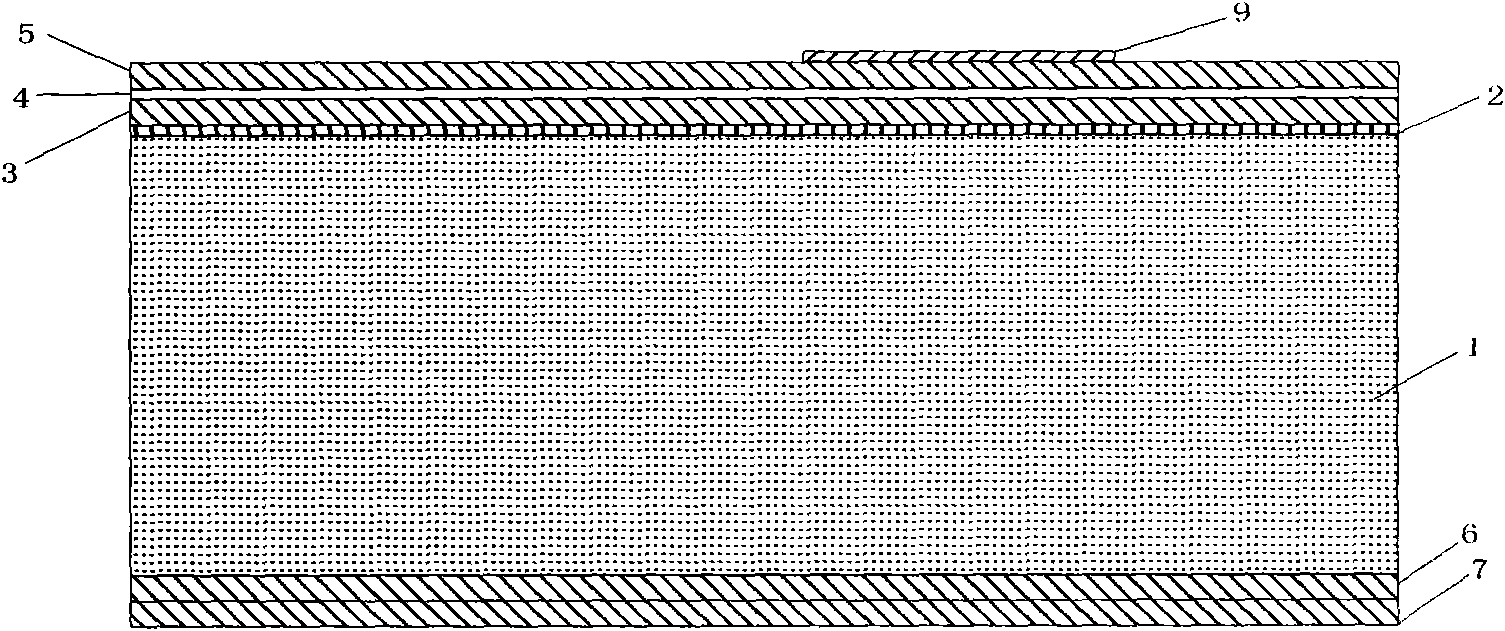

[0103] Embodiment 2, using the preparation method of the present invention to prepare a novel piezoelectric microphone chip, the steps are as follows:

[0104] 1) Clean the silicon substrate 1

[0105] Cleaning the silicon substrate 1 with an acid cleaning solution and an alkaline cleaning solution respectively, and then rinsing it with deionized water;

[0106] 2) Oxide layer formation by thermal oxidation 2

[0107] On the silicon substrate 1, use a thermal oxidation furnace to oxidize the oxide layer with a thickness of 0.2 μm, and remove the oxide layer on the reverse side, so that a thermal oxide film layer 2 with a thickness of 0.2 μm is formed on the front side of the substrate 1;

[0108] 3) Low-pressure chemical vapor deposition of the first silicon nitride film layer 3

[0109] A first silicon nitride film layer 3 with a thickness of 0.5 μm on the thermal oxide film layer 2 and a third silicon nitride mask layer 6 with a thickness of 0.5 μm on the reverse side of t...

Embodiment 3

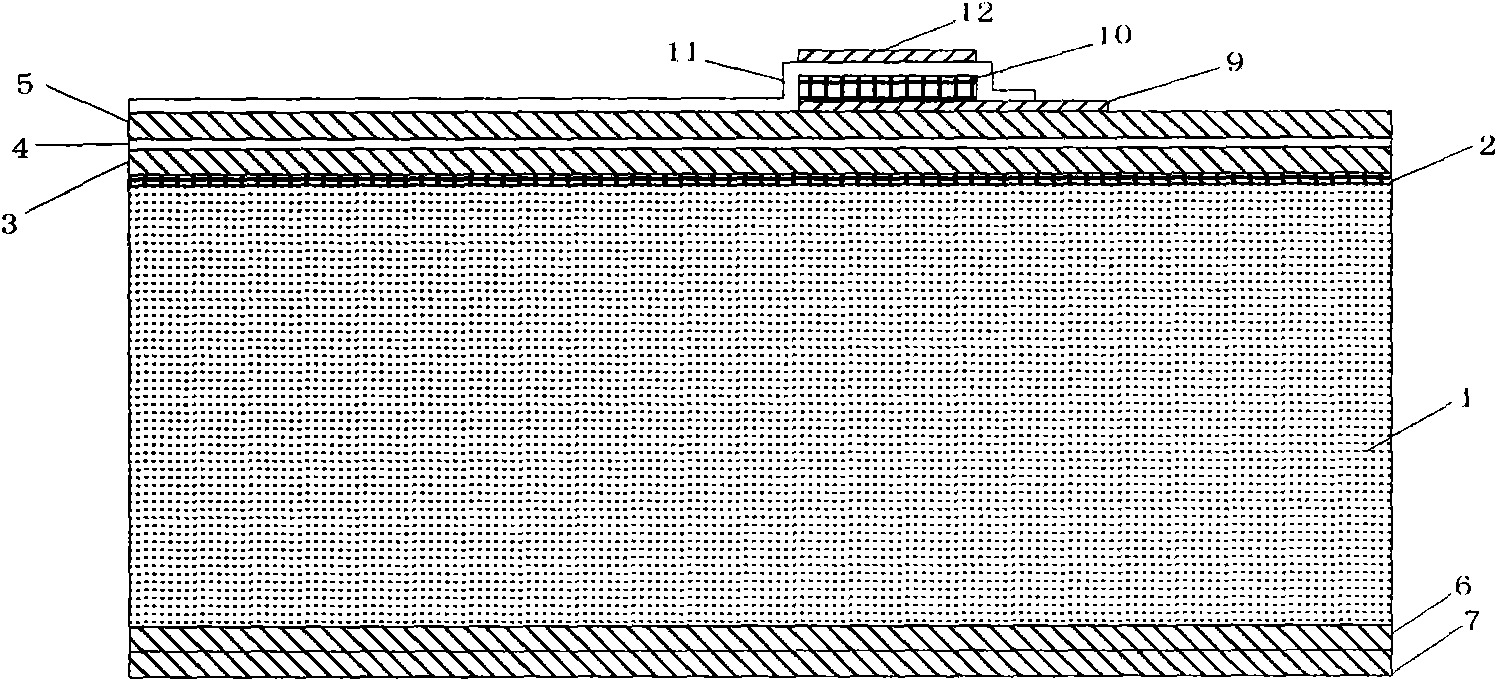

[0136] Embodiment 3, using the preparation method of the present invention to prepare a novel piezoelectric microphone chip, the steps are as follows:

[0137] 1) Clean the silicon substrate 1

[0138] Cleaning the silicon substrate 1 with an acid cleaning solution and an alkaline cleaning solution respectively, and then rinsing it with deionized water;

[0139] 2) Oxide layer formation by thermal oxidation 2

[0140] On the silicon substrate 1, use a thermal oxidation furnace to oxidize the oxide layer with a thickness of 0.2 μm, and remove the oxide layer on the reverse side, so that a thermal oxide film layer 2 with a thickness of 0.2 μm is formed on the front side of the substrate 1;

[0141] 3) Low-pressure chemical vapor deposition of the first silicon nitride film layer 3

[0142] A first silicon nitride film layer 3 with a thickness of 0.5 μm on the thermal oxide film layer 2 and a third silicon nitride mask layer 6 with a thickness of 0.5 μm on the reverse side of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com