Material for detecting indoor organic gas and method for preparing gas-sensitive element using same

A technology of organic gas and gas sensor, which is applied in the direction of analyzing materials, optomechanical equipment, and electrochemical variables of materials, etc. It can solve the problems of affecting the output of gas sensitive signals and the poor continuity of the interdigital electrode electric field, etc., to reduce the detection Extreme concentration, beneficial to miniaturization, small electrode area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1. SnCl 4 ·5H 2 O is configured as a 0.1mol / L solution, and 0.1LSnCl is taken at a molar ratio of 1:4 4 The solution was mixed with 8.4 g of citric acid until the acid was completely dissolved to obtain a transparent sol. Add 7.6ml of ammonia water dropwise until the pH of the sol is 8, and heat up to 80°C to form a white emulsion. After suction filtration, the precipitate is washed and there is no residual Cl - After (with AgNO 3 solution detection), dried in a vacuum oven at a low temperature of 80°C to obtain a xerogel, which was ground by agate to obtain 1.5g of powdered solid SnO 2 Base material, add 0.05g solid silver nitrate and 0.06g solid cadmium nitrate to SnO 2 , mixed evenly, dried in a muffle furnace at 80-100°C, and then sintered at 450°C for 1-2h to obtain 1.6g of sensitive material.

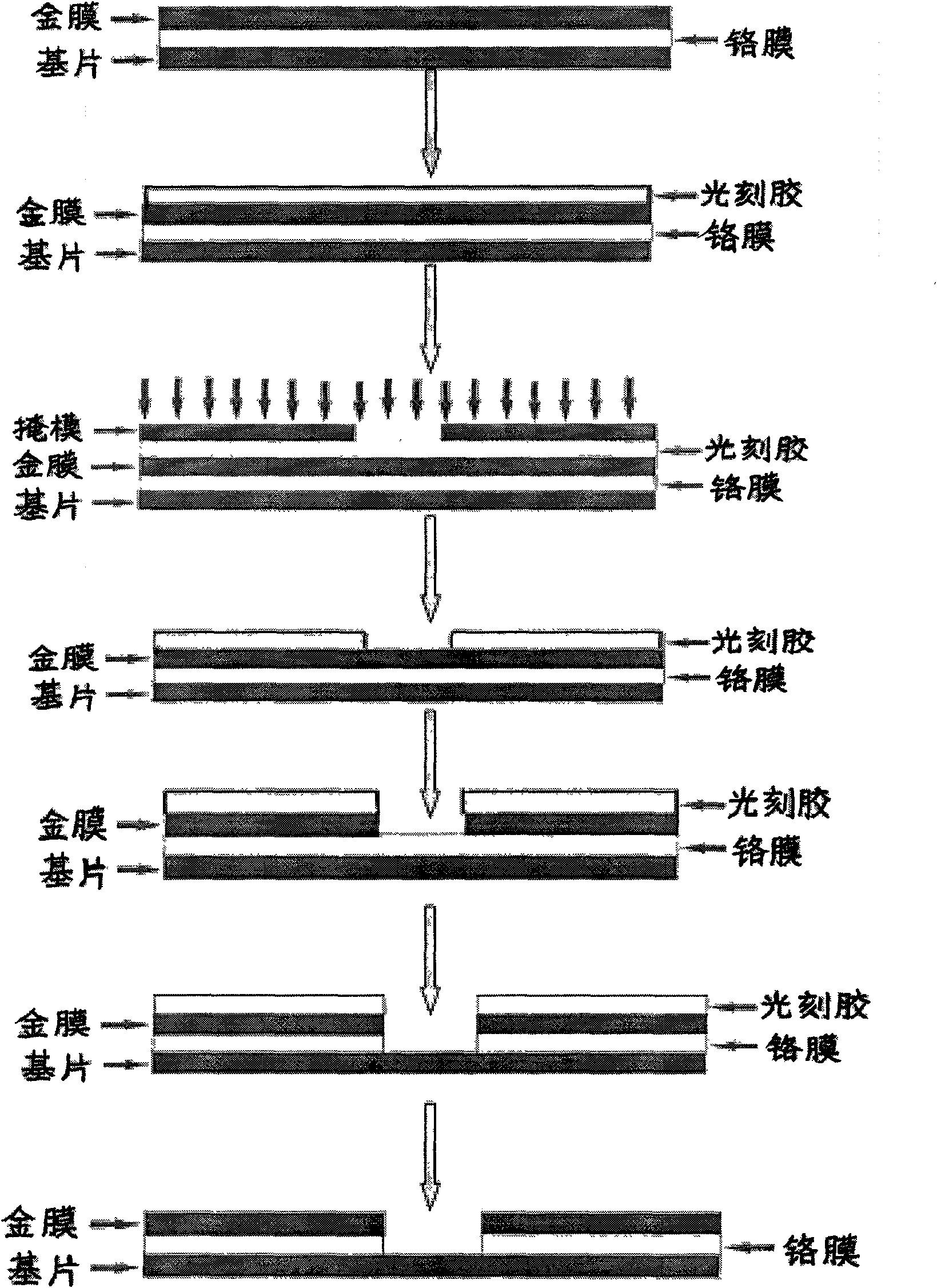

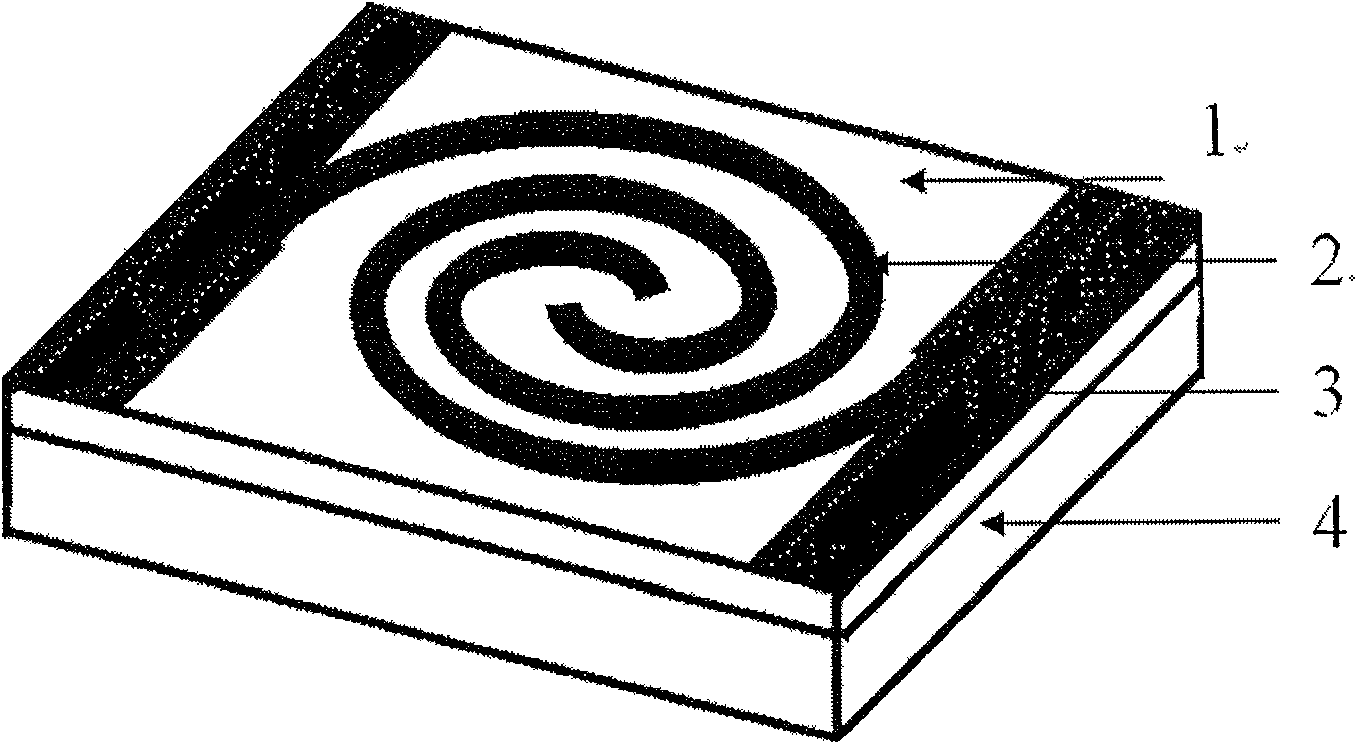

[0037] 2. The following steps of the method for preparing the gas sensor for detecting indoor organic gases (see figure 1 ):

Embodiment 2

[0045] Prepare SnO according to the method of embodiment 1 2 Base material, take 1.5gSnO 2 Base material, add 0.06g silver nitrate and 0.09g cadmium nitrate to SnO 2 , mixed evenly, dried in a muffle furnace at 80°C, and then sintered at 450°C for 2 hours to obtain 1.6g of sensitive material. According to the method of Example 1, the gas sensor for detecting the organic gas in the chamber is prepared, and the performance and effect of the obtained gas sensor are the same as those of the gas sensor of the present invention.

Embodiment 3

[0047] Prepare SnO according to the method of embodiment 1 2 Base material, take 1.5gSnO 2 Base material, add 0.08g silver nitrate and 0.13g cadmium nitrate to SnO 2 , mixed evenly, dried in a muffle furnace at 80°C, and then sintered at 450°C for 2 hours to obtain 1.6g of sensitive material. According to the method of Example 1, the gas sensor for detecting the organic gas in the chamber is prepared, and the performance and effect of the obtained gas sensor are the same as those of the gas sensor of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The total area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com