Preparation method of germanium-base schottky transistor

A technology of transistors and MOS transistors, which is applied in the field of Ge-based Schottky preparation, can solve problems such as difficulty in realizing shallow junctions, large off-state leakage current, and small on-state drive current, so as to improve morphology, reduce voids, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

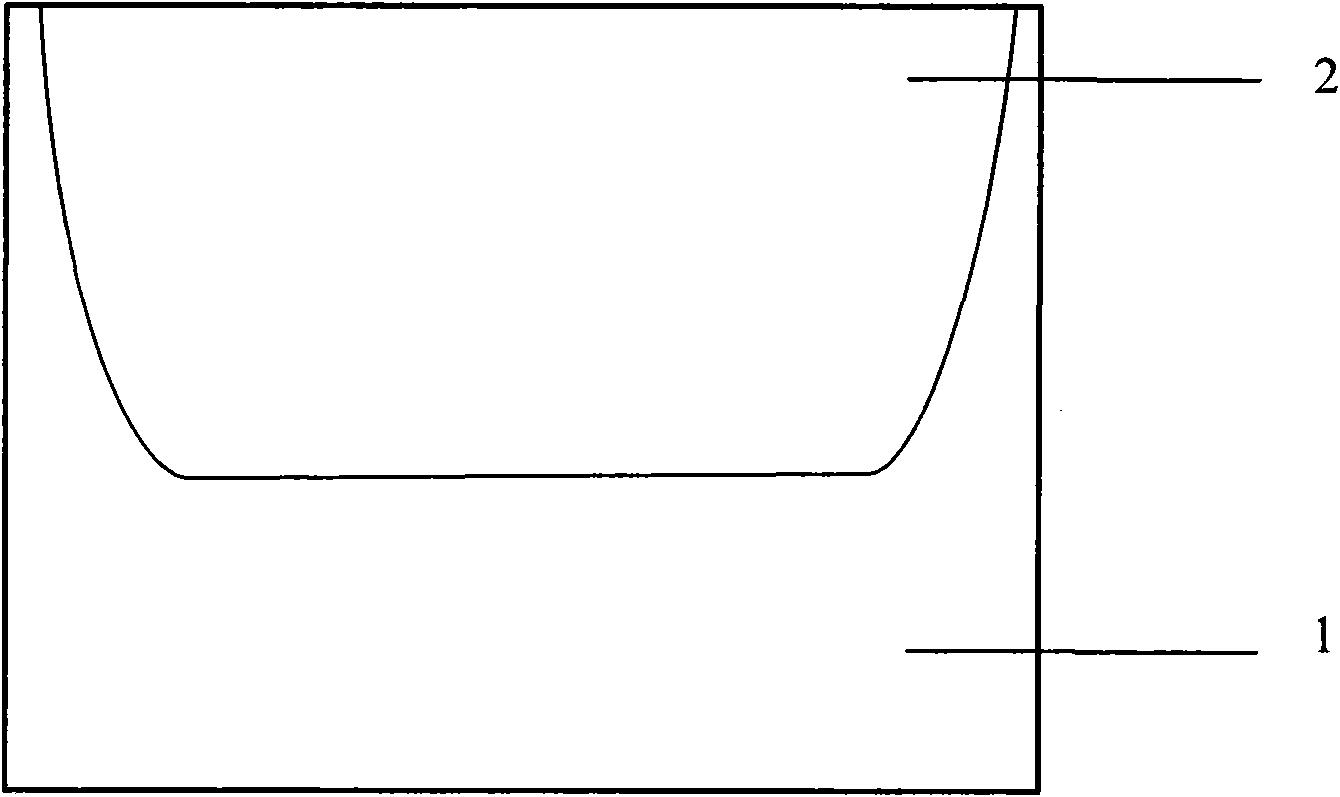

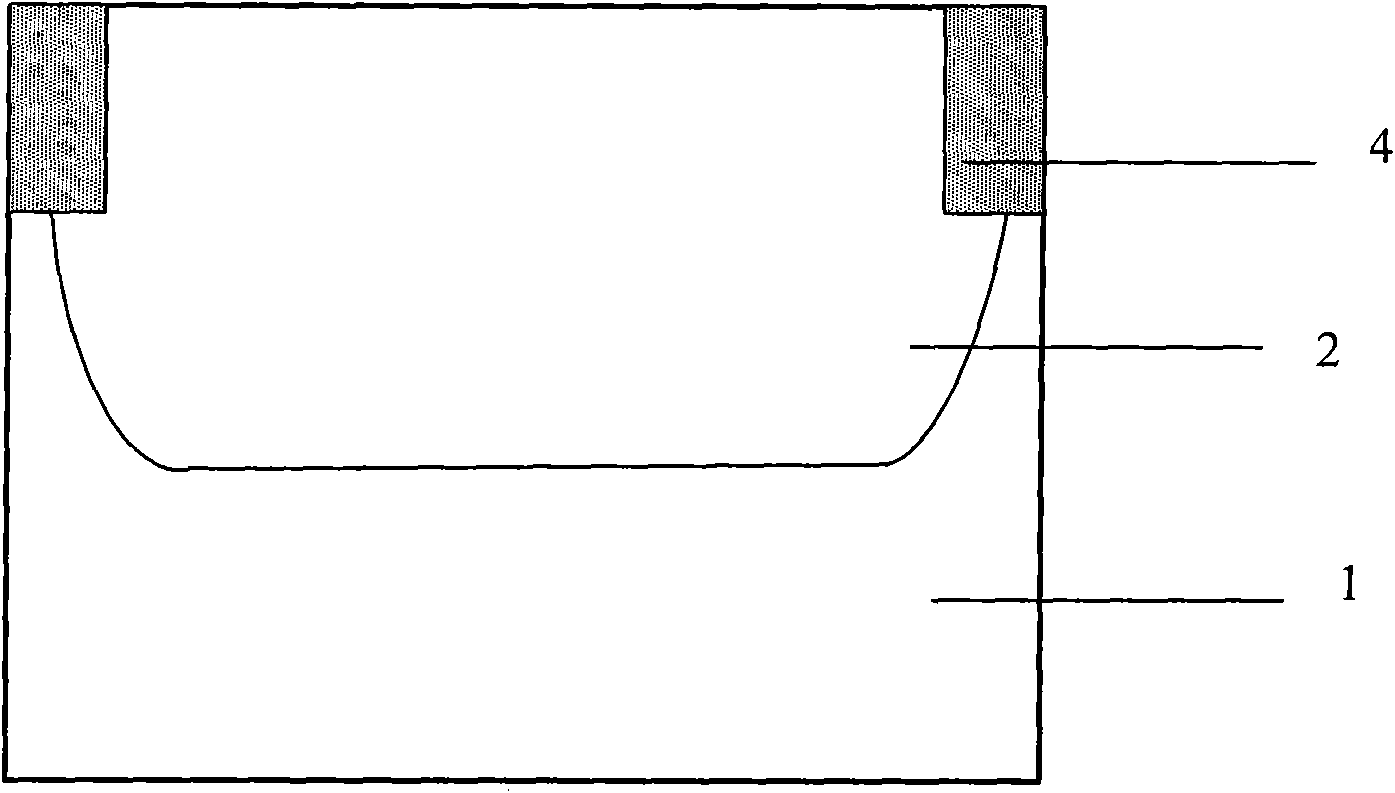

[0032] FIG. 1 is a flow chart of a method for fabricating NiGe schottky source and drain according to a preferred embodiment of the present invention. The method for making germanium-based Schottky transistor of the present invention comprises the following steps:

[0033] Step 1: Provide a germanium-based substrate. As shown in FIG. 1( a ), a semiconductor germanium substrate 1 is doped with P-type impurity Ga, wherein the semiconductor germanium substrate 1 can be a bulk germanium substrate or a germanium-on-insulator (GOI) substrate or the like.

[0034] Step 2: Fabricate the N-well region. Deposit a silicon oxide layer and a silicon nitride layer on the germanium substrate, define the N well region by photolithography, reactive ion etch away the silicon nitride in the N well region, and ion implant N-type impurities, such as phosphorus, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com