Device and process for continuously producing 2-ethyl anthracene quinone in channelization way

A pipeline-based technology for ethylanthraquinone, which is applied in the equipment and process field of pipelined continuous production of 2-ethylanthraquinone, can solve the problems of complicated mixing equipment and microwave equipment, easy corrosion of static mixer units, and poor production environment. To achieve large-scale production, easy control of reaction conditions, and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

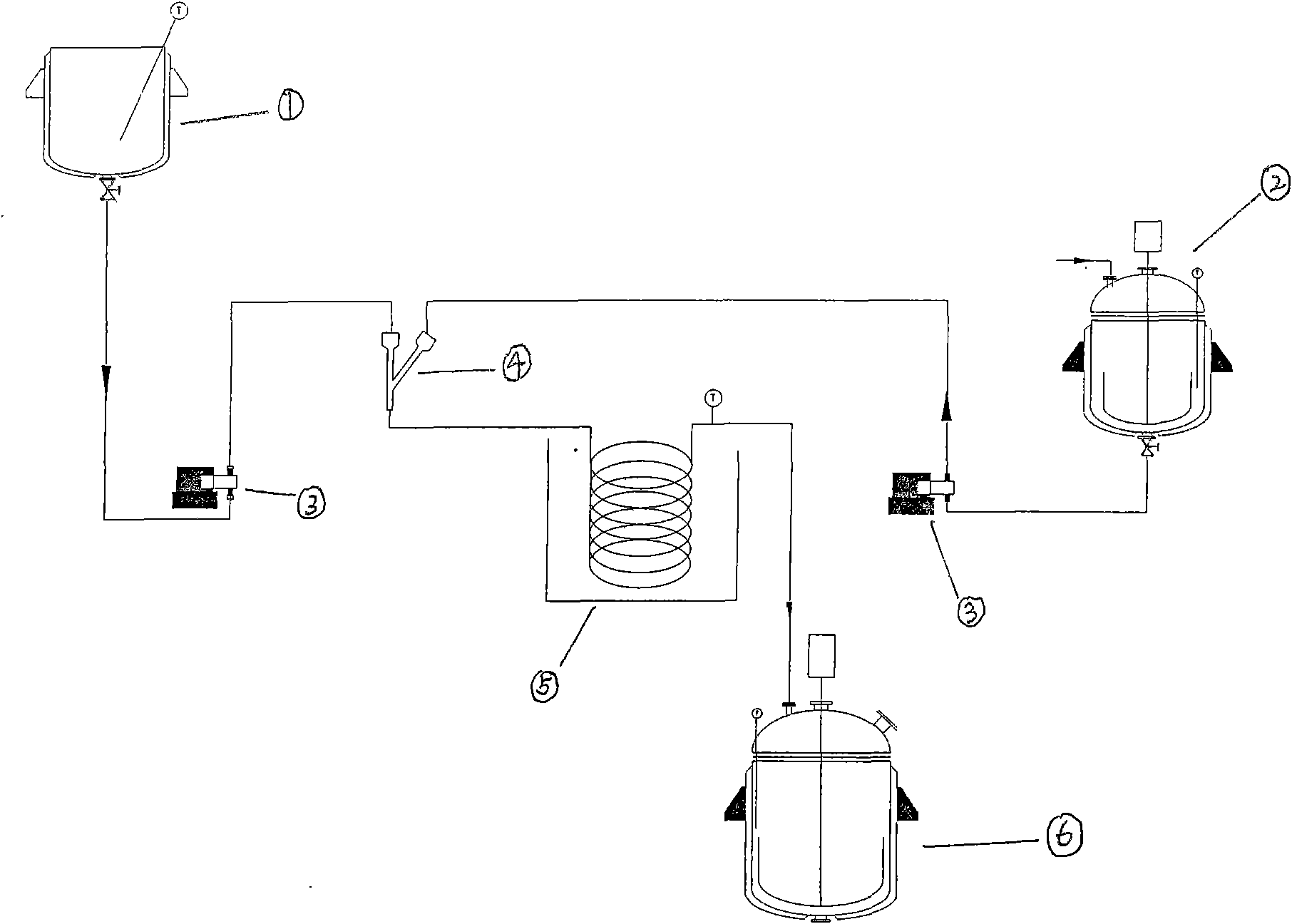

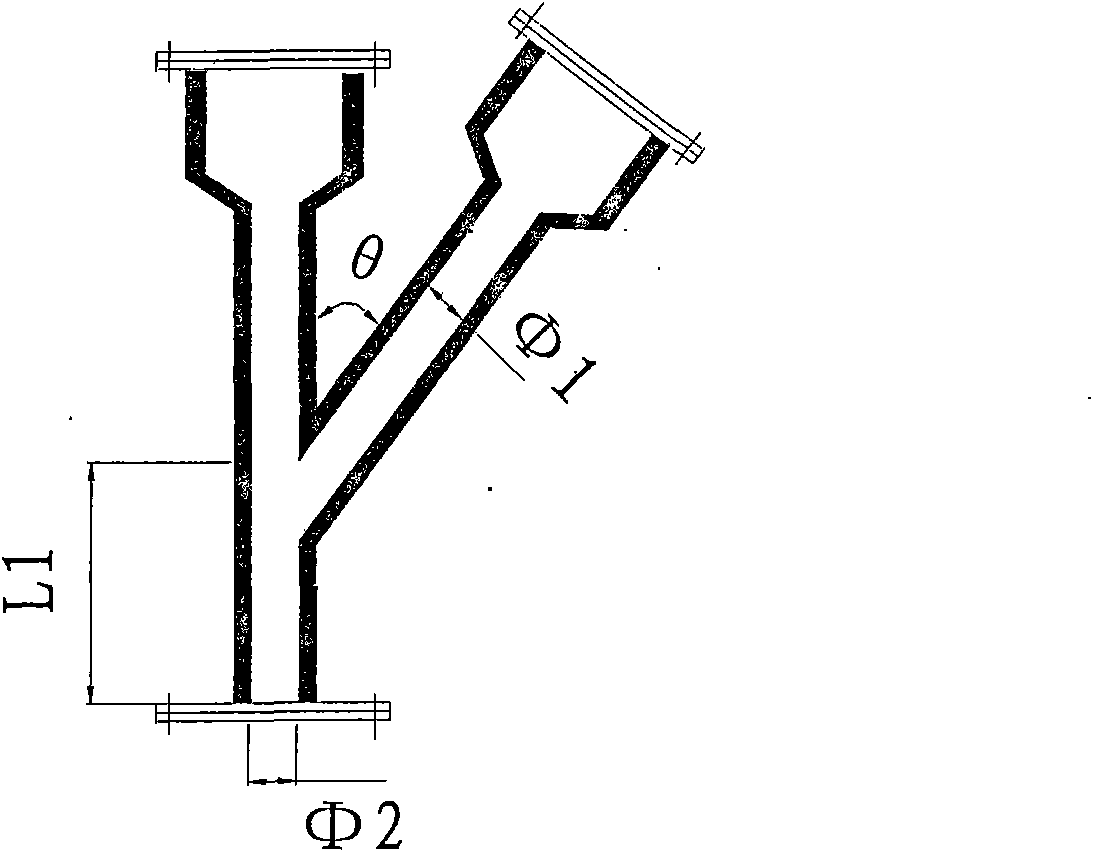

[0029] devices such as figure 1 As shown, storage tank I providing molten BEA and oleum storage tank II are respectively connected to any two inlets of Y-shaped jet mixer by respective metering pumps, and the outlet of the mixer is connected to the tube reactor, and the tube reactor The outlet is connected to the hydrolysis kettle. The reduced diameter of the inlet of the mixer is Φ1=4mm, the diameter of the outlet is Φ2=4mm, and the incident angle θ is 45 degrees. The tubular reactor is a tubular reactor with an inner diameter of Φ3=4mm and a length of 30m.

Embodiment 2

[0031] Adopt the equipment of embodiment 1, BEA is preheated to 120 ℃, 20%SO 3 Fuming sulfuric acid is preheated to 80°C, enters the Y-type jet mixer to mix, and then enters the tubular reactor. The mass ratio of BEA and oleum is 1:3, the incident angle θ is 30 degrees, and the reaction temperature is controlled at 120°C. ℃, residence time 10min, flow rate 2.2L / h, then enter the hydrolysis tank for hydrolysis, the yield is 90%.

Embodiment 3

[0033] Adopt the equipment of embodiment 1, BEA is preheated to 190 ℃, 20%SO 3 Fuming sulfuric acid is preheated to 60°C, mixed in a Y-shaped jet mixer, and then enters a tubular reactor. The mass ratio of BEA and oleum is 1:1, the incident angle θ is 60 degrees, and the reaction temperature is controlled at 180°C. ℃, residence time 2min, flow rate 11.3L / h, then enter the hydrolysis tank for hydrolysis, the yield is 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com