Micro Pirani gage

A Raney meter and miniature technology, applied in the direction of microstructure technology, microstructure device, manufacturing microstructure device, etc., can solve the problems of large volume and insufficient sensitivity, and achieve the effect of small volume, high sensitivity and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

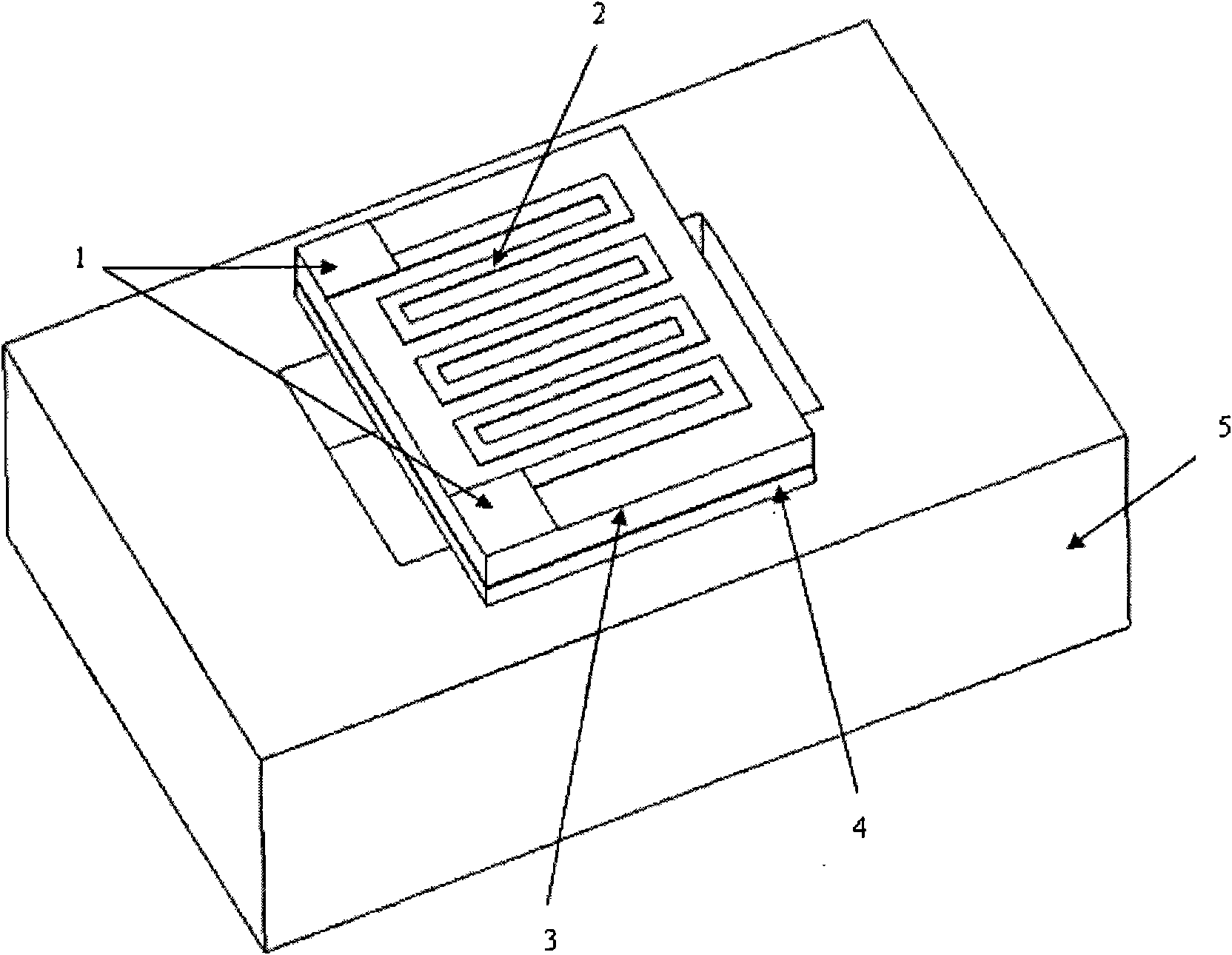

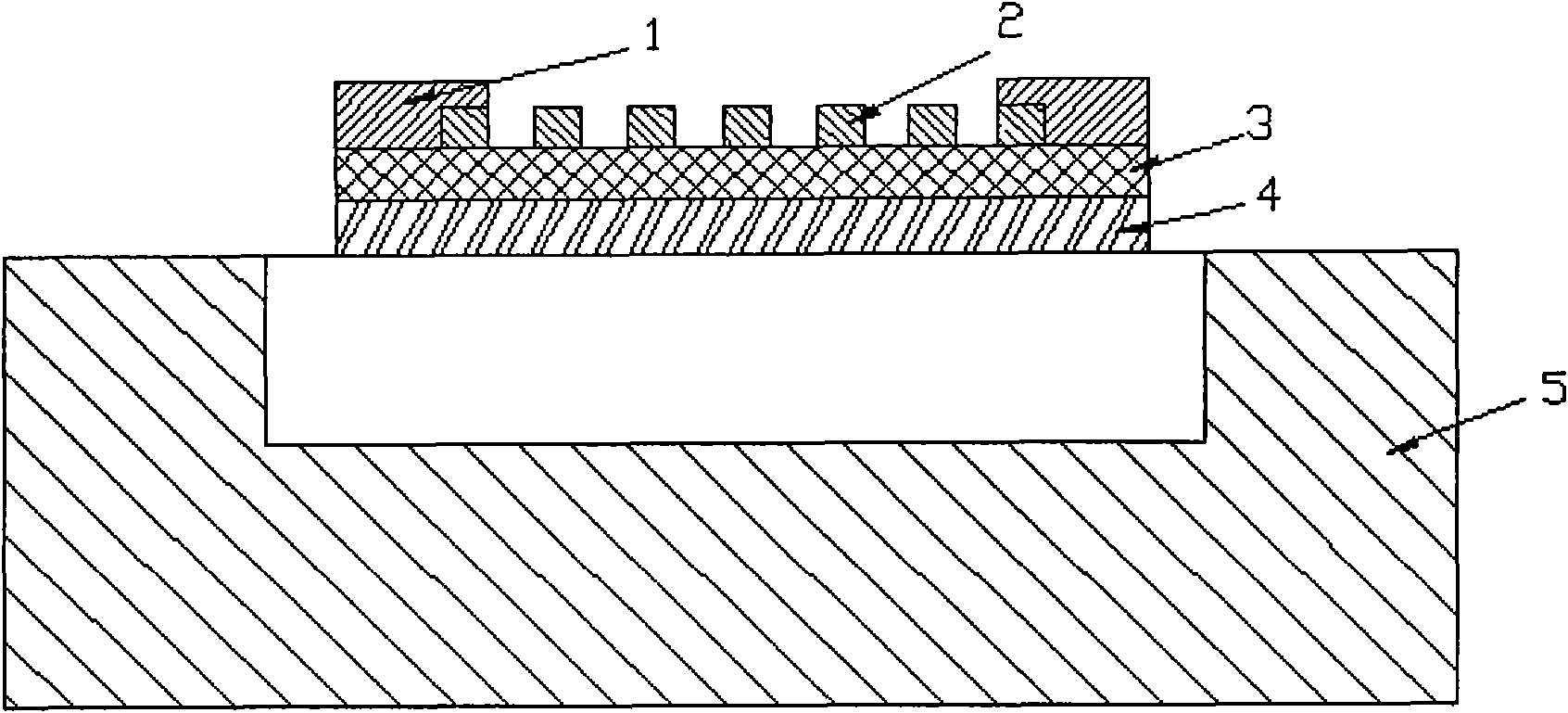

[0034] Embodiment one, such as figure 2 As shown, the silicon substrate 5 is single crystal silicon, and the heating body 2 is platinum metal with a curved shape; the metal electrode 1 is composed of a sputtered Au layer on the surface of the Ti adhesion layer;

[0035] The insulating layer 3 is made of silicon nitride with a thickness of 250nm; the heat insulating layer 4 is made of silicon dioxide with a thickness of 1um.

[0036] The preparation method of this embodiment comprises the following steps in sequence:

[0037] (1) As shown in Figure 3 (A), get a single crystal silicon wafer (2 ", 400um thick, double polishing, (100) orientation) as substrate 5; As shown in Figure 3 (B) on the substrate 5 thermally oxidize the silicon dioxide thin film insulation layer 4 on the surface, and then deposit a low-stress 250nm-thick silicon nitride insulating layer 3 with a low-stress chemical vapor deposition (LPCVD) process; as shown in Figure 3 (C), and then removing the thermal...

Embodiment 2

[0041] Embodiment 2, when the volume of the cavity of the device is large, a part of the back side of the silicon substrate is etched away by a wet method to form a cavity, such as Figure 4 shown. The silicon substrate 5 is single crystal silicon, and the heating body 2 is platinum metal with a curved shape; the metal electrode 1 is composed of a Cu layer sputtered on the surface of the Ti adhesion layer;

[0042] The insulating layer 3 is made of silicon nitride with a thickness of 250nm; the heat insulating layer 4 is made of silicon dioxide with a thickness of 1um.

Embodiment 3

[0043] Embodiment 3, the silicon substrate 5 is polycrystalline silicon, the heating body 2 is nickel metal with a curved shape; the metal electrode 1 is formed by sputtering a Pt layer on the surface of the Ti adhesion layer and then sputtering an Au layer;

[0044] The insulation layer 3 is made of silicon dioxide with a thickness of 250nm; the heat insulation layer 4 is formed by stacking two layers of films, the upper layer is made of silicon nitride with a thickness of 500nm, and the lower layer is made of silicon dioxide with a thickness of 250nm.

[0045] The sandwich structure composed of silicon dioxide-silicon nitride-silicon dioxide can reduce stress.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com