Titanium alloy surface boronizing method

A titanium alloy and boronizing technology, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve the unfavorable high temperature boronizing of titanium alloy, increase the contact area between titanium alloy and oxygen, and increase the looseness of boronizing agent. It is easy to prepare, prevent high temperature oxidation, and reduce pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

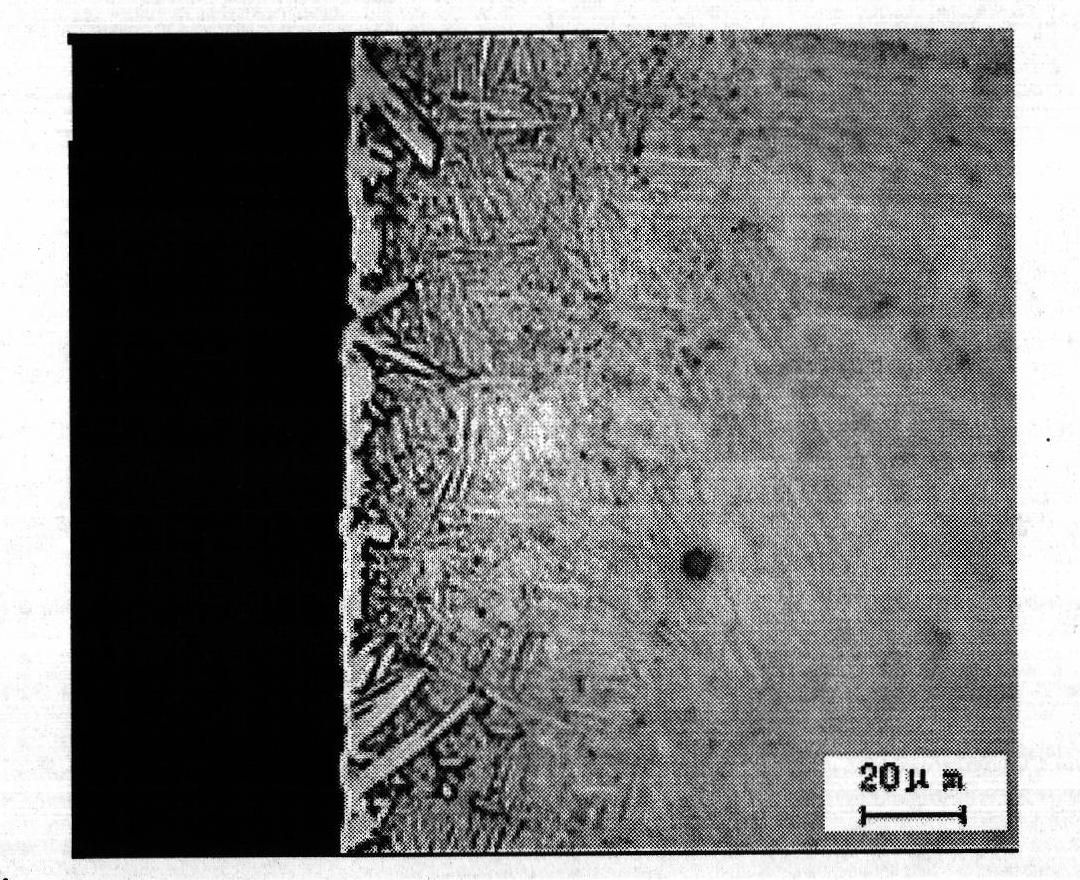

Image

Examples

Embodiment 1

[0040] The boronizing agent used is B 4 C powder, particle size ≤ 0.1mm (obtained by grinding with a sealed laboratory crushing sample maker).

[0041]The TC4 (Ti-6Al-4V) titanium alloy plate was wire-cut into a sample of 10mm×10mm×3mm.

[0042] The boronizing agent is used to perform boronizing treatment on the surface of the titanium alloy, and the steps are as follows.

[0043] 1. Titanium alloy surface pretreatment

[0044] ① Degreasing

[0045] Soak the titanium alloy material in a degreasing agent at 70°C for 2 hours; the degreasing agent is Na 2 CO 3 、Na 3 PO 4 12H 2 O, Na 2 SiO 3 and OP-10 emulsifier dissolved in water to obtain the following concentration of aqueous solution:

[0046] Na 2 CO 3 20g / L, Na 3 PO 4 12H 2 O 10g / L, Na 2 SiO 3 10g / L, OP-10 emulsifier 2g / L.

[0047] ②Washing

[0048] Soak the titanium alloy material in hot water at 70°C for 1 hour, and then rinse it twice with deionized water at room temperature.

[0049] ③Surface polish...

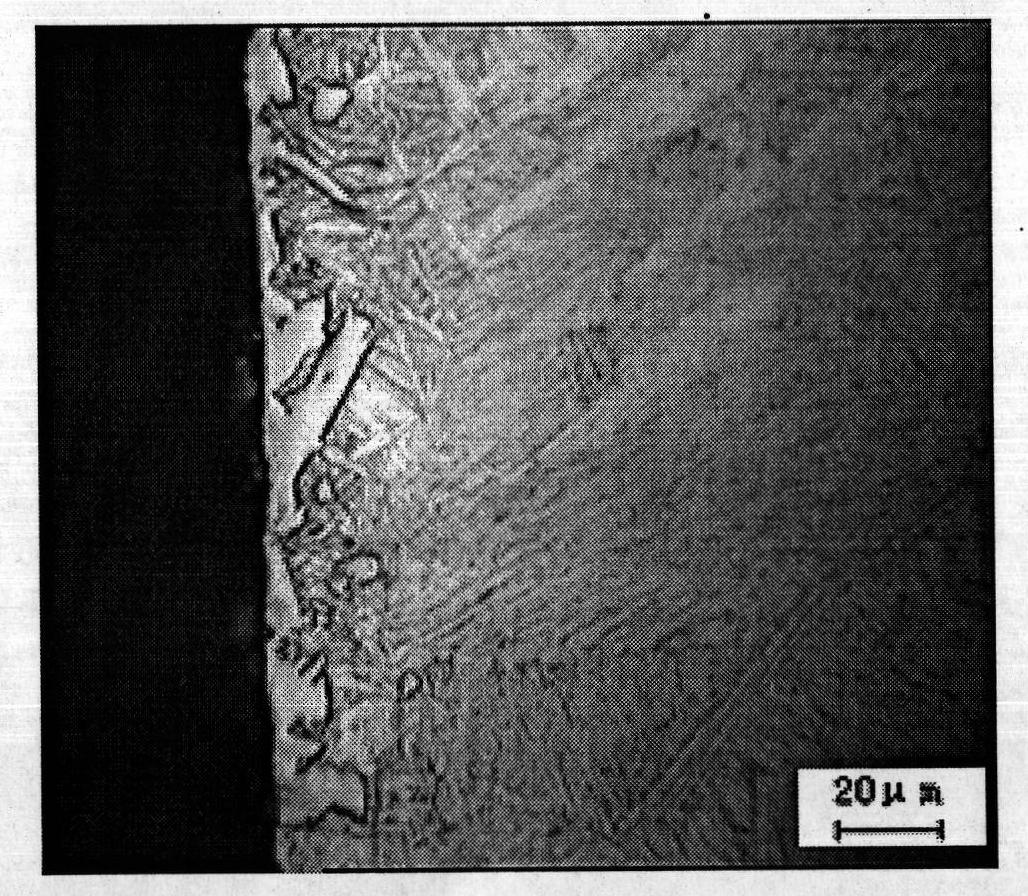

Embodiment 2

[0060] The boronizing agent used is B 4 C powder, particle size ≤ 0.1mm (obtained by grinding with a sealed laboratory crushing sample maker).

[0061] The TC4 (Ti-6Al-4V) titanium alloy plate was wire-cut into a sample of 10mm×10mm×3mm.

[0062] The boronizing agent is used to perform boronizing treatment on the surface of the titanium alloy, and the steps are as follows.

[0063] 1. Titanium alloy surface pretreatment

[0064] ① Degreasing

[0065] Soak the titanium alloy material in a degreasing agent at 80°C for 1 hour; the degreasing agent is Na 2 CO 3 、Na 3 PO 4 12H 2 O, Na 2 SiO 3 and OP-10 emulsifier dissolved in water to obtain the following concentration of aqueous solution:

[0066] Na 2 CO 3 30g / L, Na 3 PO 4 12H 2 O 15g / L, Na 2 SiO 3 15g / L, OP-10 emulsifier 5g / L.

[0067] ②Washing

[0068] Soak the titanium alloy material in hot water at 80°C for 0.5 hours, and then rinse it twice with deionized water at room temperature.

[0069] ③Surface pol...

Embodiment 3

[0080] The boronizing agent used is B 4 C powder, particle size ≤ 0.1mm (obtained by grinding with a sealed laboratory crushing sample maker).

[0081] The TC4 (Ti-6Al-4V) titanium alloy plate was wire-cut into a sample of 10mm×10mm×3mm.

[0082] The boronizing agent is used to perform boronizing treatment on the surface of the titanium alloy, and the steps are as follows.

[0083] 1. Titanium alloy surface pretreatment

[0084] ① Degreasing

[0085] Immerse the titanium alloy material in a degreasing agent at 60°C for 3 hours; the degreasing agent is Na 2 CO 3 、Na 3 PO 4 12H 2 O, Na 2 SiO 3 and OP-10 emulsifier dissolved in water to obtain the following concentration of aqueous solution:

[0086] Na 2 CO 3 10g / L, Na 3 PO 4 12H 2 O 5g / L, Na 2 SiO 3 5g / L, OP-10 emulsifier 2g / L.

[0087] ②Washing

[0088] Soak the titanium alloy material in hot water at 60°C for 2 hours, and then rinse it with deionized water at room temperature for 3 times.

[0089] ③Surface...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com