Organ silicon material for encapsulating power-type LED and synthetic method thereof

A technology of LED packaging and synthesis method, applied in the fields of electronic chemicals and polymer science, can solve the problems of lack of silicone resin synthesis method, affecting the service life, poor adhesion, etc., achieving excellent thermal aging ability, not easy to poison, improve permeability Effects of Light Rate and Hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

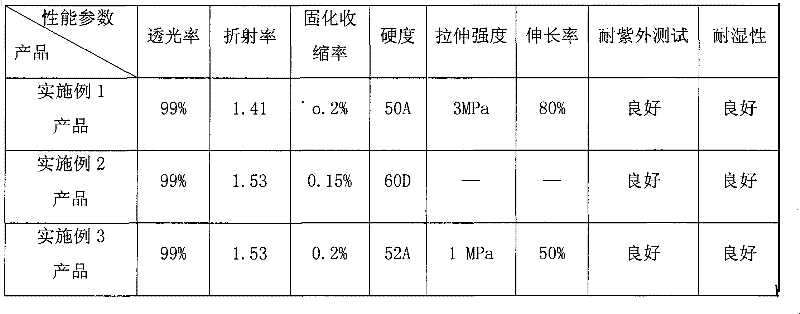

Examples

Embodiment 1

[0052] Vinyl silicone resin synthesis method step in component A is as follows:

[0053] (1) Add 255.2 grams of trimethylchlorosilane, 38.6 grams of vinyldimethylethoxysilane, 500 grams of tetraethyl orthosilicate, 100 grams of butanol, 1000 grams of xylene and 0.5 gram of aluminum triisopropoxide, stirred evenly;

[0054] (2) Add 600 grams of distilled water dropwise when the temperature is 30°C, and the dropping time is controlled within 2 hours;

[0055] (3) After adding dropwise and reacting at 80°C for 4 hours, add 30 grams of vinyldimethylethoxysilane dropwise, add dropwise for 1 hour, and then react for 8 hours;

[0056] (4) Pour out the layers, take the resin and the solvent part and react at 80° C. for another 6 hours;

[0057] (5) After the reaction is finished, wash with water, filter, and remove unreacted matter and solvent to obtain vinyl-containing MQ silicone resin; the preparation of vinyl-terminated polysiloxane in component A is as follows:

[0058] (1) Ad...

Embodiment 2

[0064] The synthesis steps of silicone resin in component A are as follows:

[0065] (1) Add 11.7 grams of trimethylchlorosilane, 22 grams of vinyldimethylethoxysilane, 35.6 grams of methyltriethoxysilane and 38 grams of vinyltriethoxysilane into a 3000ml four-necked flask , 253.8 grams of phenyltrichlorosilane, 83.2 grams of ethyl orthosilicate, 100 grams of isopropanol, 1000 grams of xylene and 0.7 gram of aluminum triisopropoxide, stirred evenly;

[0066] (2) Add 850 grams of distilled water dropwise when the temperature is 30°C, and the dropping time is controlled within 2 hours;

[0067] (3) After the dropwise addition of 80°C for 2 hours, add 32 grams of vinyldimethylethoxysilane, 28.2 grams of methylvinyldichlorosilane, 168 grams of methylphenyldiethoxysilane, two The dropping time of 101.2 grams of phenyldichlorosilane is controlled within 2 hours;

[0068] (4) After 4 hours of reaction after the dropwise addition, 30 grams of vinyldimethylethoxysilane and 10 grams o...

Embodiment 3

[0079] The synthesis steps of siloxane in component A are as follows:

[0080] (1) Add 35.3 grams of methyl vinyl dichlorosilane, 51.6 grams of dimethyl dichlorosilane, D 4 100 grams, 100 grams of octaphenylcyclotetrasiloxane, 315 grams of methylphenyldiethoxysilane, 379.5 grams of diphenyldichlorosilane, 800 grams of xylene and 1 gram of zinc benzoate, stir well;

[0081] (2) drip 80 grams of distilled water;

[0082] (3) Slowly raise the temperature to 90-110°C for reaction, react for 3 hours, observe the viscosity change, add 15 grams of vinyldimethylethoxysilane dropwise, and react for another 6 hours;

[0083] (4) After the reaction is finished, wash with water, filter, and remove unreacted substances and solvents to obtain methylphenyl vinyl siloxane;

[0084] The synthesis steps of siloxane in component B are as follows:

[0085] (1) Add 40.3 grams of methylhydrogen dichlorosilane, 64.5 grams of dimethyl dichlorosilane, D 4 100 grams, 100 grams of octaphenylcyclotet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com