Apparatus and method for manufacturing resin-impregnated cured sheet, and apparatus and method for manufacturing carbonaceous material sheet

a technology of resin impregnated cured sheet and cured sheet, which is applied in the direction of dough shaping, manufacturing tools, applications, etc., can solve the problems of reducing the electroconductivity of the substrate itself, and affecting the quality of the produ

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

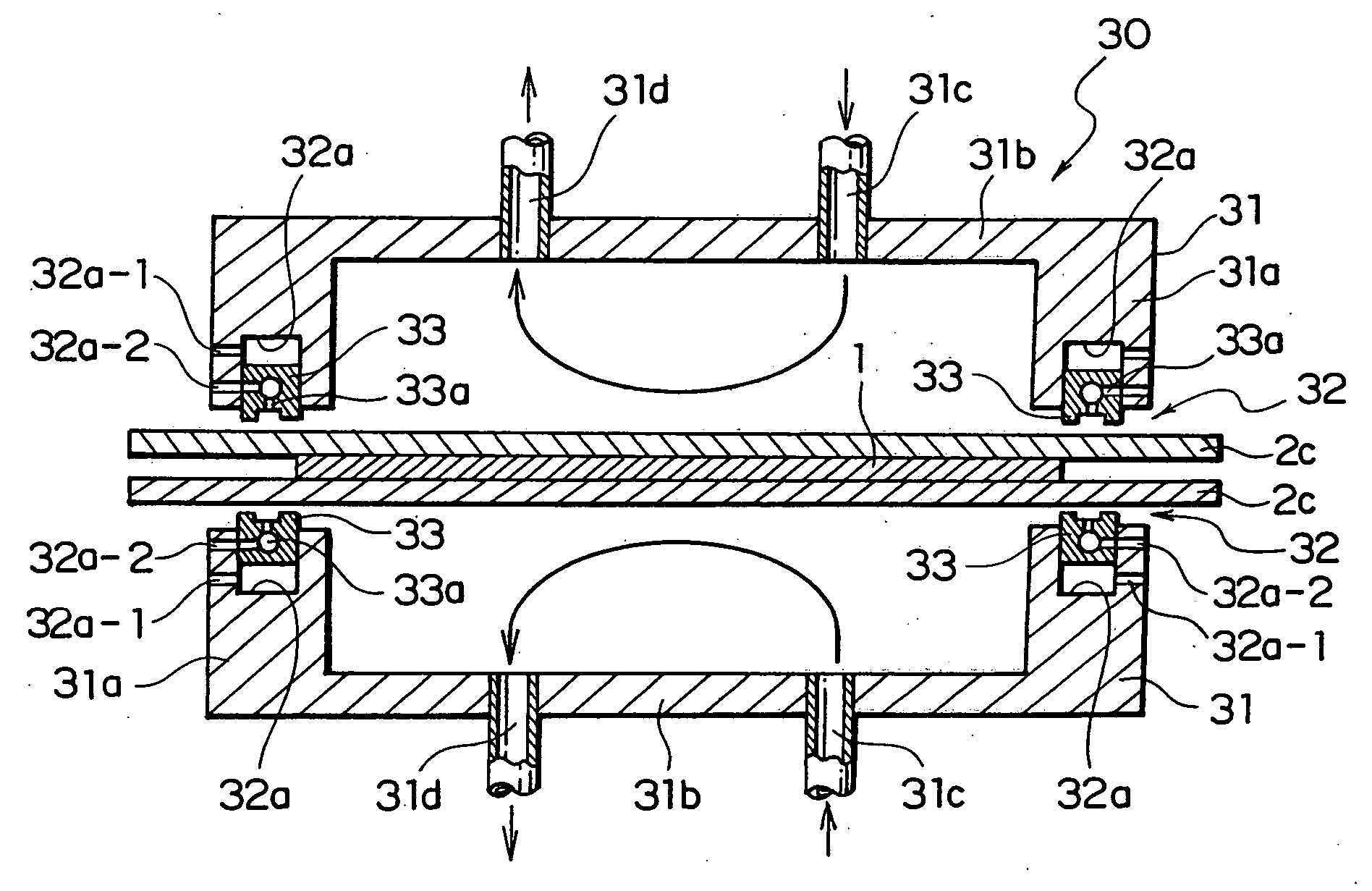

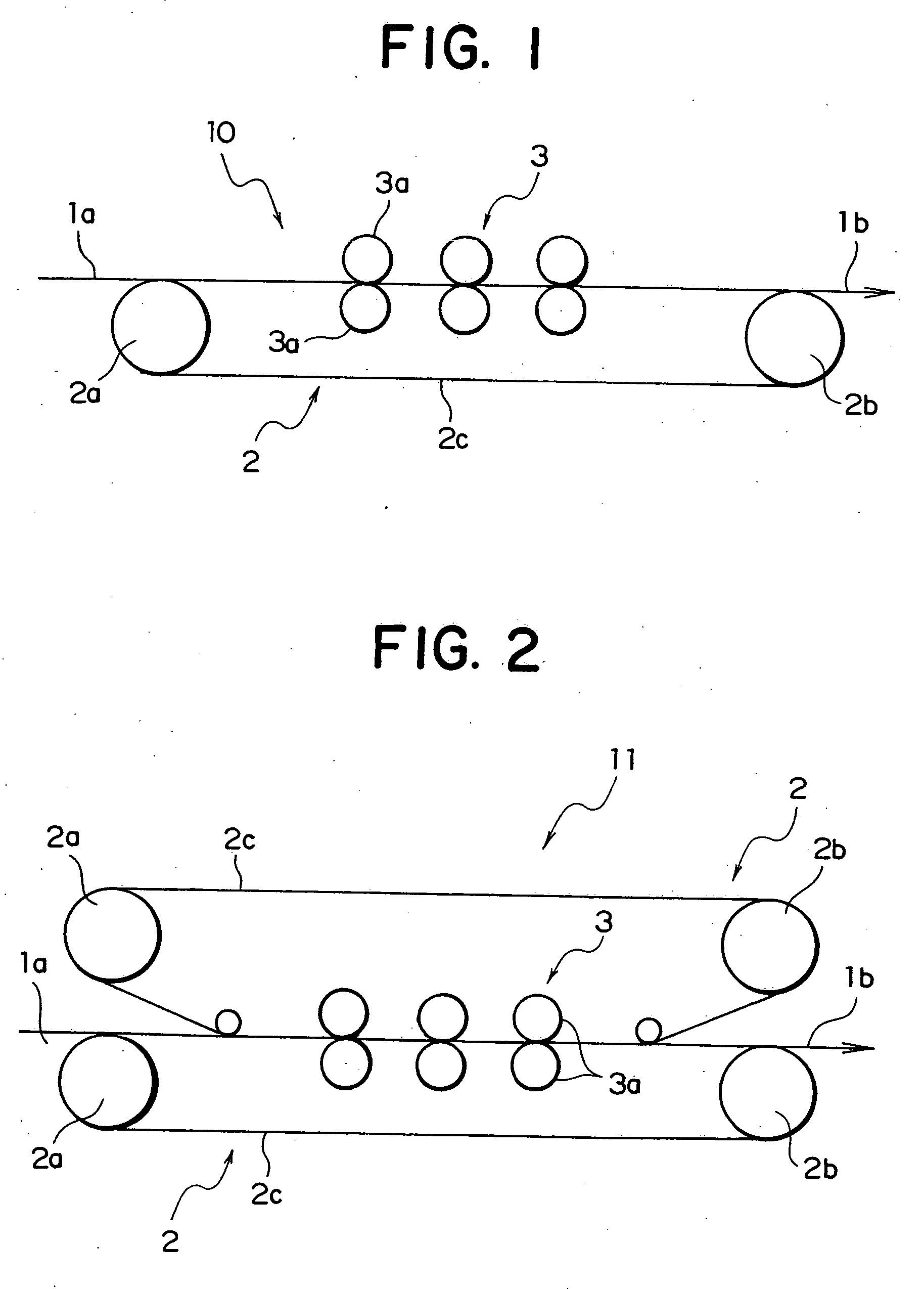

[0100] An apparatus for manufacturing a resin-impregnated cured sheet, which was equipped with a preheating section, heating and pressuring rolls, and two sets of endless belts, was used. Hot wind of 200.degree. C. was flown into the preheating section, such that the belt temperature was set at 135.degree. C. Further, the press was carried out by the successive first heating and pressuring roll at 300.degree. C. and under a line pressure of 6.6.times.10.sup.4 N / m, so that the curing treatment was continuously carried out.

[0101] Then, the carbonization treatment was carried out and the carbonaceous material sheet obtained was wound up in a roll form in the same manner as in Example 1.

[0102] The obtained carbonaceous material sheet had no problem of a crack, a fragment or the like, and was excellent in its handling property with a bending strength of 82 Mpa, so that it had a good quality. Further, it was verified that productivity is also high since a long carbonaceous material sheet ...

example 3

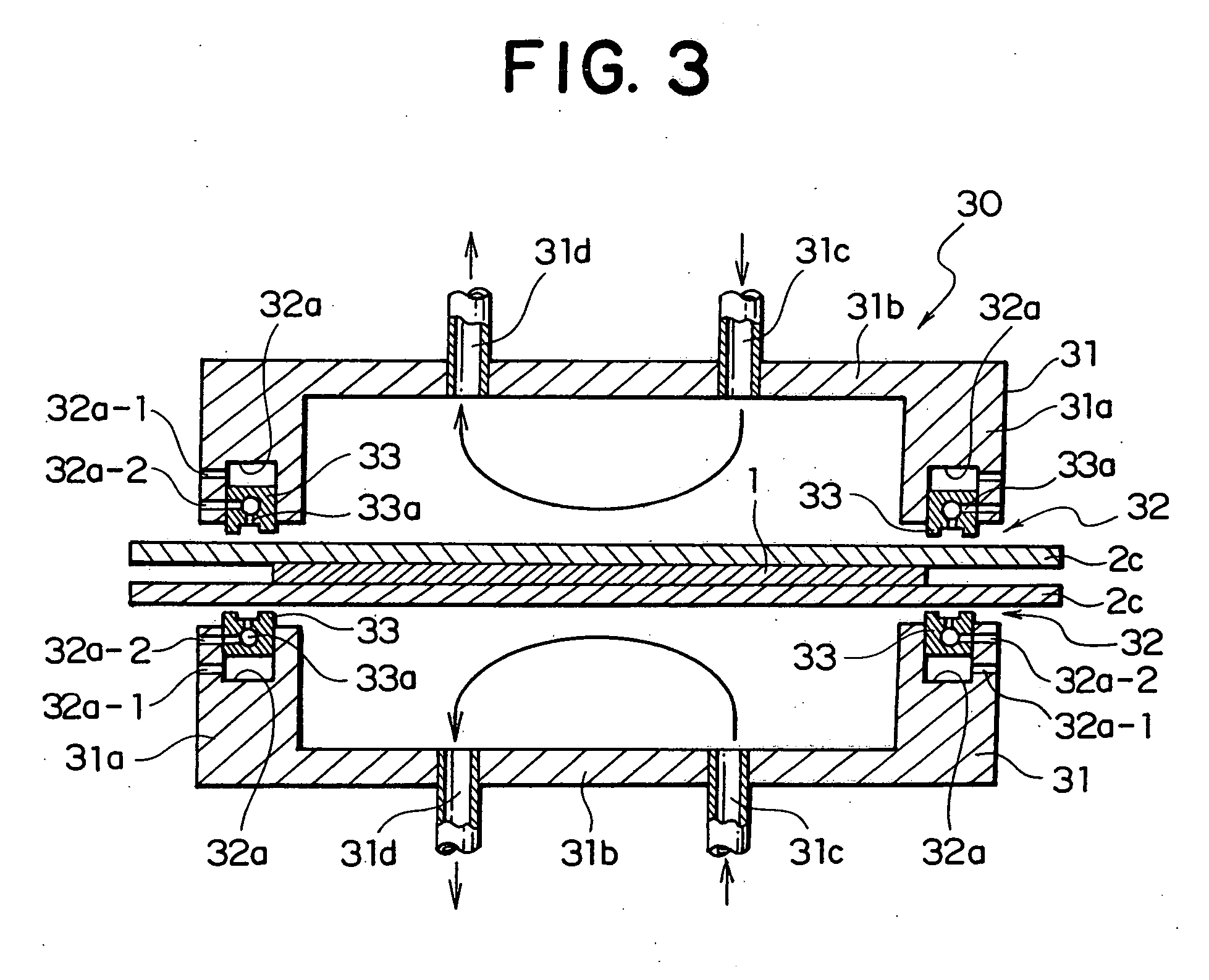

[0103] The curing treatment was continuously carried out in the same condition as in Example 1 in the apparatus for manufacturing the resin-impregnated cured sheet of Example 1, except that the heating and pressuring device shown in FIG. 3 was used as the resin curing means in place of the heating and pressuring rolls, the nip pressure was set to be 5.times.10.sup.4 N / m.sup.2, and the residential time in the device was set to be 2 minutes.

[0104] Then, carbonization treatment was carried out and the carbonaceous material sheet obtained was wound up in a roll form in the same manner as in Example 1.

[0105] The obtained carbonaceous material sheet had smooth surface and uniform thickness, had no crack, fragment or the like, and was excellent in its handling property with a bending strength of 85 Mpa. Thus, it has a good quality. Further, since a long carbonaceous material sheet can be continuously produced, productivity is also extremely high.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| operational temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com