Improved composite electrical adhesive tape and processing method thereof

An electrical tape, pressure-sensitive adhesive technology, applied in the direction of film/sheet adhesive, adhesive, adhesive type, etc., can solve the problem of poor surface wetting ability of metal core material or plastic sheath substrate Meet the requirements of insulation and sealing, damage sealing performance and electrical insulation performance, etc., achieve excellent insulation and self-adhesion, eliminate hidden dangers of easy failure, and improve the effect of wetting ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] An improved processing technology of composite electrical tape:

[0031] ① mixing polyisobutylene and butyl rubber or isoprene rubber as the main raw material;

[0032] ② Calendering to make a 51mm×1.0mm×3m substrate-free base material, the thickness of the base material layer is 1.0mm;

[0033] ③Scrape or spray solvent-based rubber pressure-sensitive adhesive HX-902 directly on the above-mentioned base material. About 9.5h, the thickness of the pressure-sensitive adhesive layer is about 15μm after drying;

[0034] ④ Composite the above-mentioned base material coated with pressure-sensitive adhesive with release film or release paper and roll it into a disc-shaped product.

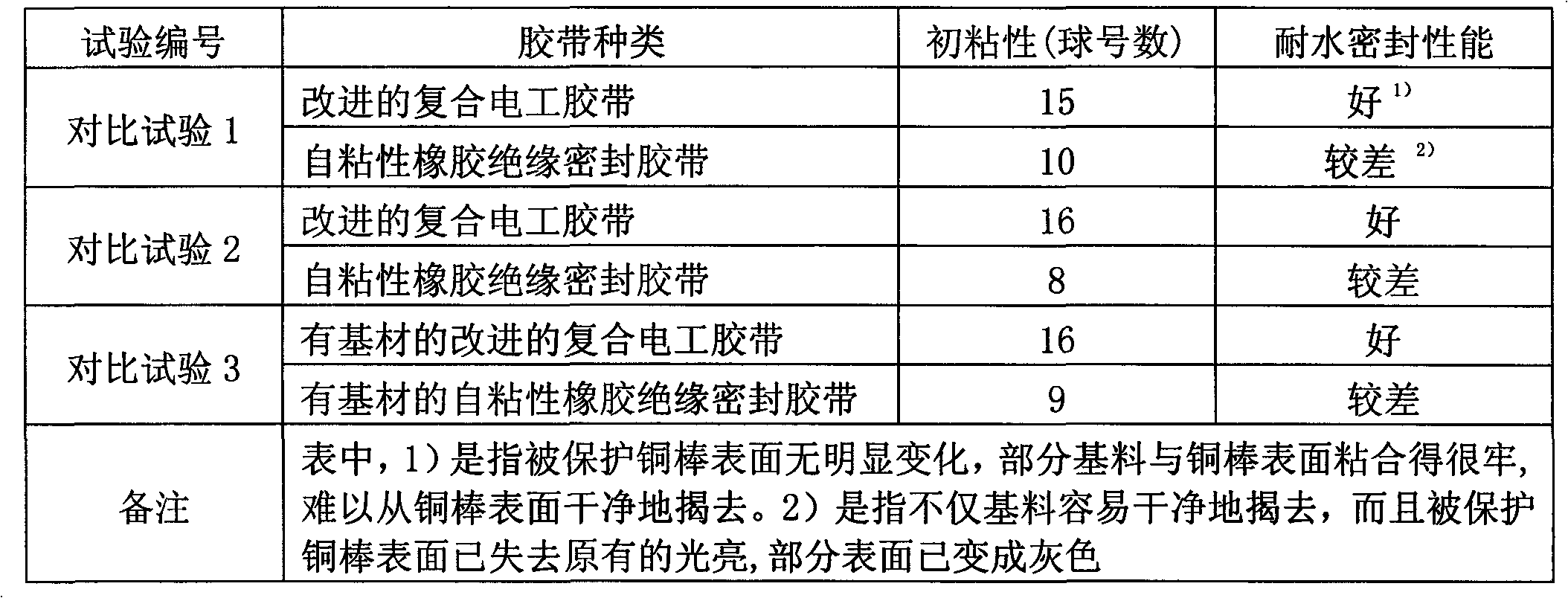

[0035] The prepared improved composite electrical tape was tested for its initial adhesion and water-resistant sealability, and the results are shown in Table 1 for the results of Comparative Test 1.

Embodiment 2

[0037] In this example, an improved composite electrical tape is prepared, and the preparation method is the same as in Example 1.

[0038] The difference is that a layer of solvent-based acrylate pressure-sensitive adhesive is coated on the surface of the base material calendered with polyisobutylene and butyl rubber or isoprene rubber as the main material. The measured solvent-based acrylate The properties of the pressure-sensitive adhesive are: initial tack of 16, 180°peel strength of 7.0N / 25mm, stickiness of about 9.5h, and the thickness of the pressure-sensitive adhesive layer after drying is about 3μm.

[0039] The prepared improved composite electrical tape was tested for initial tack and water resistance, and the results were as follows:

[0040] 1) The initial viscosity is 11;

[0041]2) Water-resistant sealing effect: the rubber base material is easier to remove, and the surface of the protected copper rod has partially lost its original brightness.

[0042] The ab...

Embodiment 3

[0044] This example introduces another processing technology of the improved composite electrical tape.

[0045] ① Mixing the rubber compound with polyisobutylene and butyl rubber or isoprene rubber as the main raw material;

[0046] ② Calender the above-mentioned mixed rubber material into a base material of 51mm×1.0mm×3m, and the thickness of the base material layer is 1.0mm.

[0047] ③Scratch the hot-melt acrylic pressure-sensitive adhesive glue solution on the release film or release paper. The measured initial tack of the hot-melt acrylic pressure-sensitive adhesive is 16, and the 180° peel strength is 7.1N / 25mm. About 9.0h, the thickness of the pressure-sensitive adhesive layer after drying is about 5μm;

[0048] ④Compound the release film or release paper with the base material coated with pressure-sensitive adhesive, and transfer the pressure-sensitive adhesive on the release film or release paper to the base material.

[0049] The prepared improved composite electri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com