Halogen-free and flame-retardant polyethylene cable material

A technology of flame-retardant cable material and polyethylene, applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., to reduce the formation of gaps, excellent flame-retardant effects, and promote the formation of surface carbides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

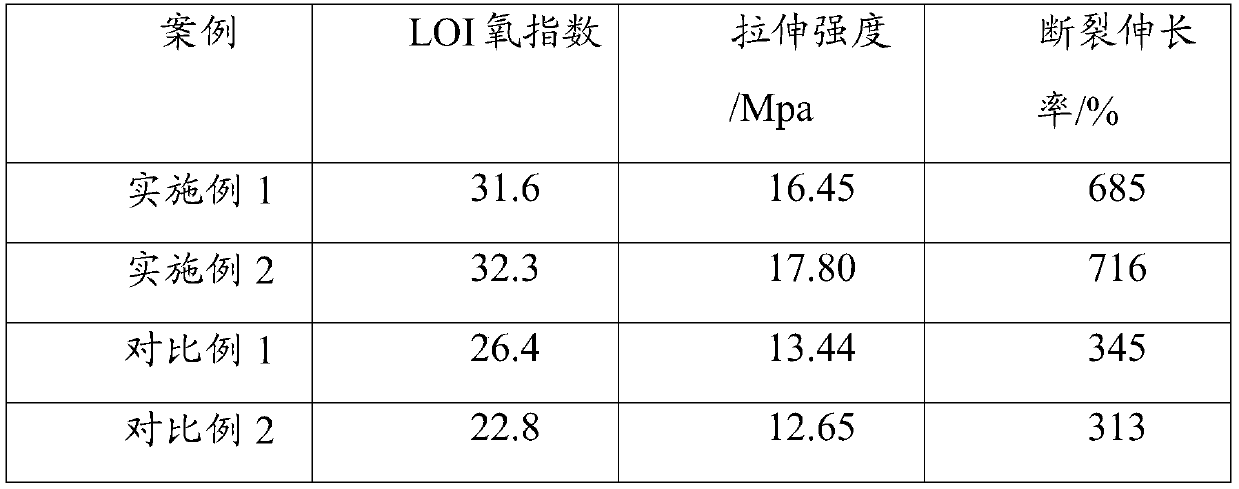

Embodiment 1

[0023] The total weight of polyethylene halogen-free flame retardant cable material is 10 kg, of which low-density polyethylene resin accounts for 78%, phosphate-modified ultra-fine calcium carbonate (average particle size 2.5μm) accounts for 16%, oleic acid amide accounts for 1.5% %, triglycidyl epoxyphenyl silane accounts for 4%, and stearic acid accounts for 0.5%. Mix uniformly in advance in a high mixer according to the above ratio, then plasticize and granulate in an extruder, and then use a flat vulcanizer to mold to obtain a test sample.

Embodiment 2

[0025] The total weight of polyethylene halogen-free flame retardant cable material is 10 kg, of which low-density polyethylene resin accounts for 70%, phosphate-modified ultrafine calcium carbonate (average particle size 1.6 μm) accounts for 22%, and oleic acid amide accounts for 22% %, triglycidyl epoxyphenyl silane accounts for 5%, and stearic acid accounts for 1%. Mix uniformly in advance in a high mixer according to the above ratio, then plasticize and granulate in an extruder, and then use a flat vulcanizer to mold to obtain a test sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com