A-site doped K2NiF4 type cathode material of intermediate-low temperature solid oxide fuel cell

A fuel cell and cathode material technology, which is applied to solid electrolyte fuel cells, fuel cell parts, battery electrodes, etc., can solve the problems of reducing non-stoichiometric oxygen content, affecting the ionic conductivity of materials, and improving service life, The effect of improving ionic conductivity and improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

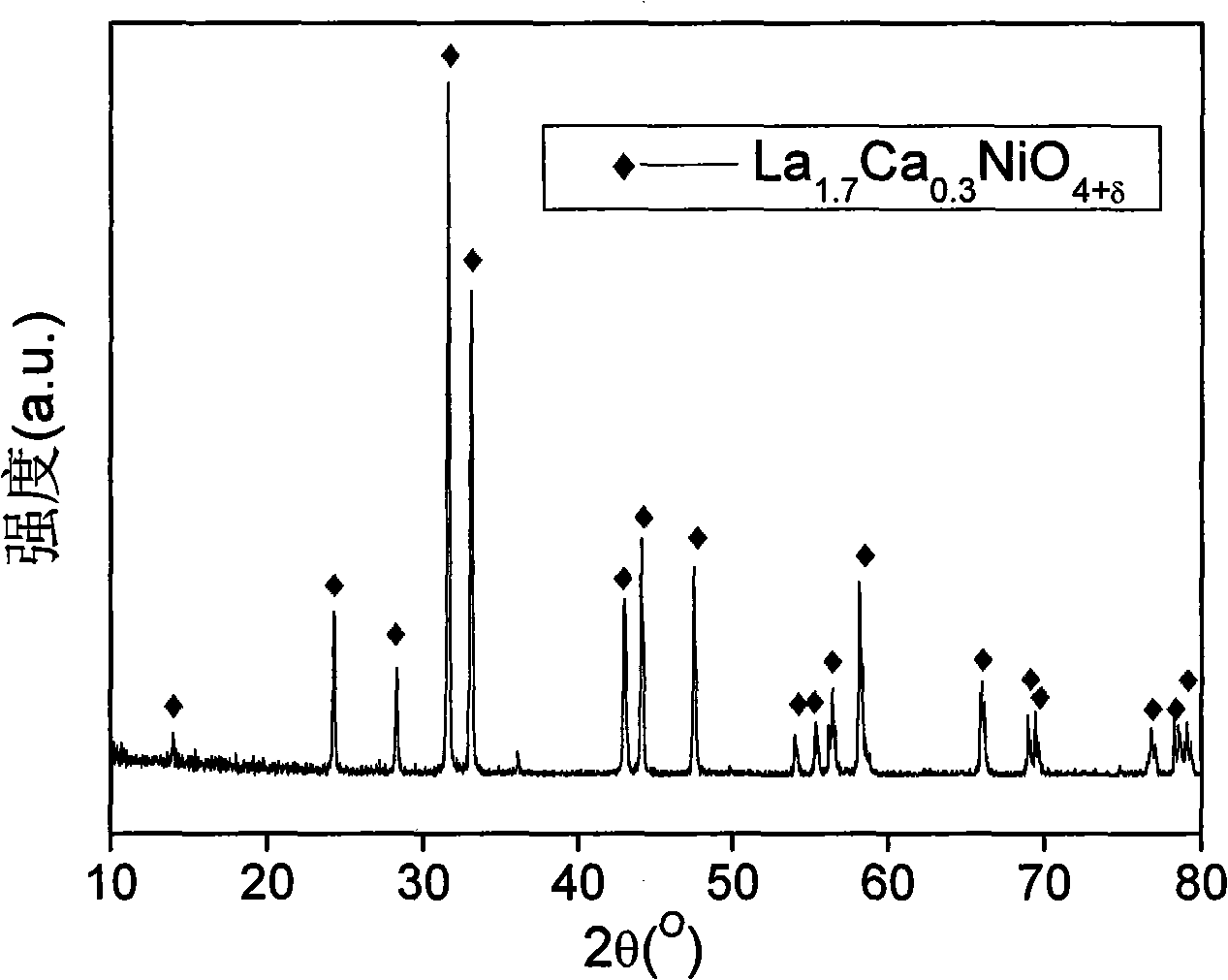

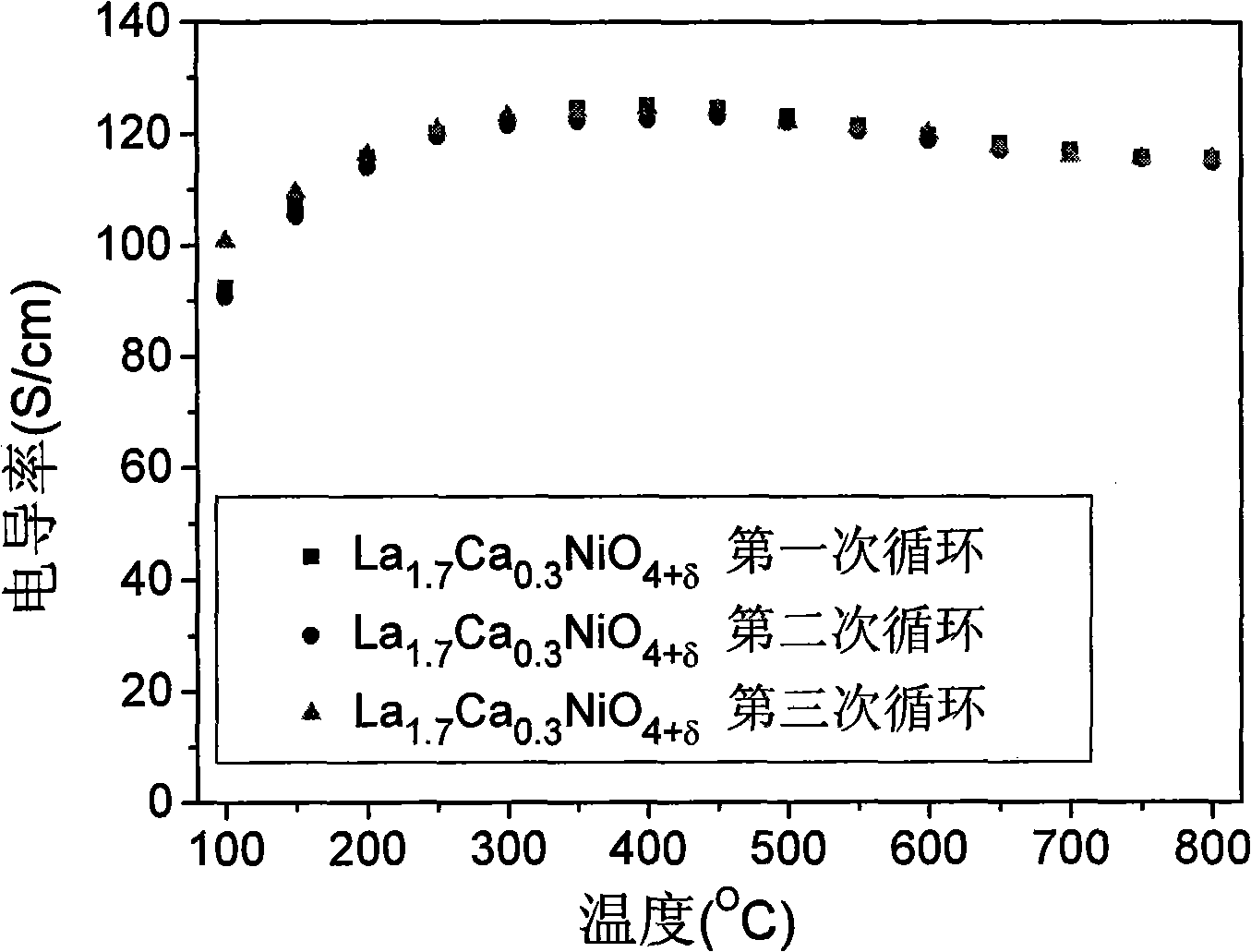

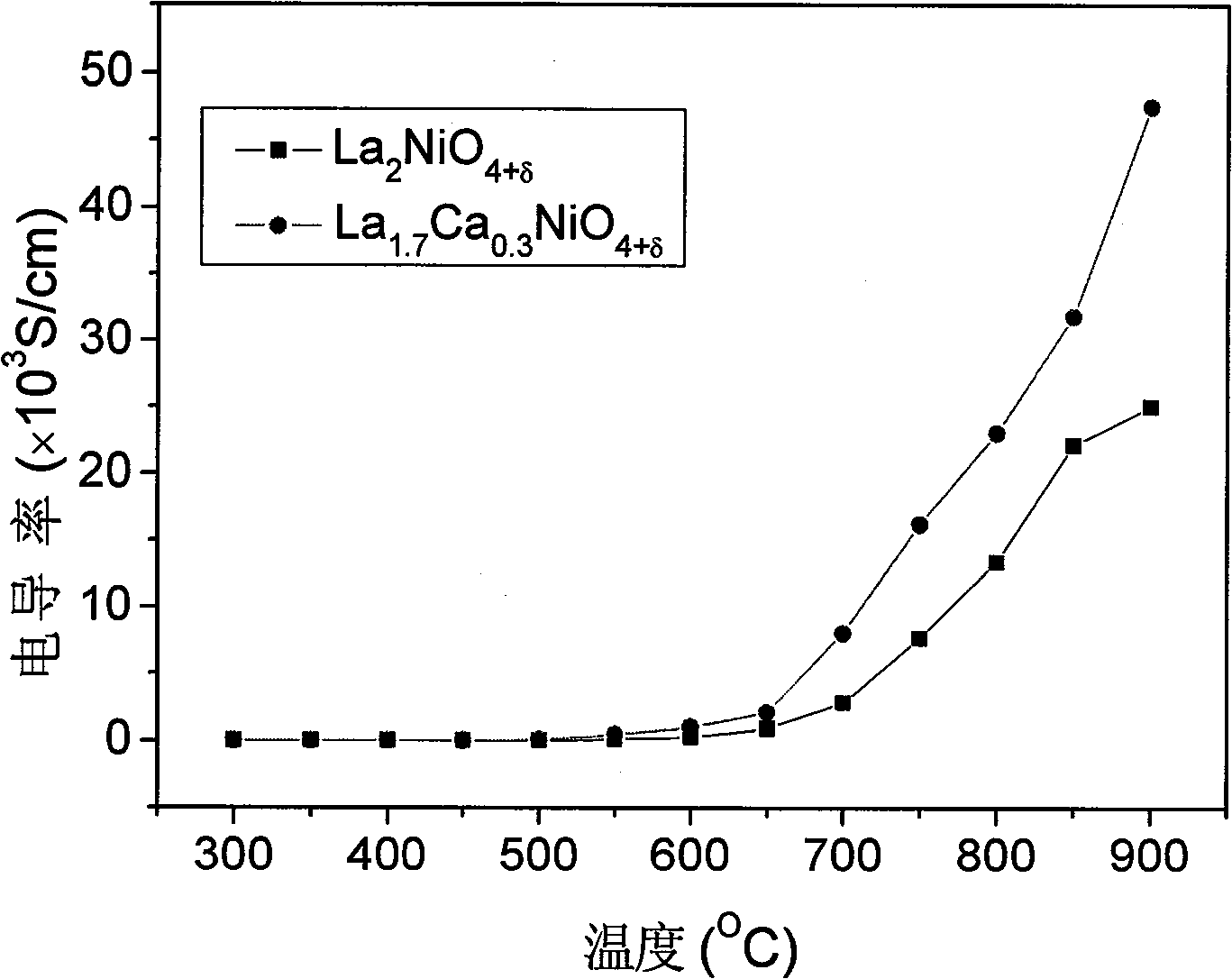

[0013] Example 1: La 1.7 Ca 0.3 NiO 4+δ Synthesis, conductivity testing and chemical compatibility testing of

[0014] Press La 1.7 Ca 0.3 NiO 4+δ The stoichiometric ratio, weigh an appropriate amount of La 2 o 3 ,. La 2 o 3 Dissolve in dilute nitric acid solution, then add Ni(NO 3 ) 2 ·6H 2 O, Ca(NO 3 ) 2 4H 2 O. According to the metal ion / citric acid ratio of 1:1.5, an appropriate amount of citric acid was weighed and dissolved in the above solution. Stir well, mix evenly, and evaporate in a water bath at 80°C to obtain a gel. Heating the gel to about 300°C, the gel burns to obtain the precursor powder. The precursor powder was calcined at 950°C for 8 hours to obtain the desired cathode powder material La 1.7 Ca 0.3 NiO 4+δ . The synthesized powder was added with 40% by volume of carbon powder and 2% by volume of PVA solution, mixed and dry-pressed, and the prepared sample was kept at 1350° C. for 5 hours to make a porous anode material.

[0015] The obt...

Embodiment 2

[0017] Example 2: La 1.8 Ca 0.2 NiO 4+δ Synthesis of Nitrate-Glycine Method and Preparation of Cathodic Membrane

[0018] Take La(NO 3 ) 3 ·6H 2 O, Ni(NO 3 ) 2 ·6H 2 O, Ca(NO 3 ) 2 4H 2 O is raw material, according to: La 1.8 Ca 0.2 NiO 4+δ The ratio of the elements weighed an appropriate amount of nitrate, dissolved in deionized water. At the same time, weigh glycine into the above solution according to the metal ion / glycine ratio of 1 / 1.5, stir and mix. Evaporate in a water bath at 70°C to obtain a green gel. Continue heating the gel to about 300°C, the gel burns to obtain the precursor powder. The above precursor was ground and calcined at 800 °C for 12 hours to obtain La 1.8 Ca 0.2 NiO 4+δ cathode material. Take a certain amount of powder, add 10% mass fraction of soluble starch and 1% mass fraction of ethyl cellulose, and finally add 1ml of deionized water, mix evenly and apply it evenly on the dense electrolyte fired at high temperature by screen prin...

Embodiment 3

[0019] Example 3: La 1.9 Ca 0.1 NiO 4+δ solid phase synthesis

[0020] Press La 1.9 Ca 0.1 NiO 4+δ The stoichiometric ratio of La 2 o 3 , basic nickel carbonate (analytical pure) and CaCO 3 (analytical pure). Pour the above materials into a ball mill jar, use agate balls as the grinding medium, and alcohol as the dispersant. After mixing and grinding for 5 hours, dry the mixed slurry, and then calcinate at 1100°C for 10 hours to obtain the tetragonal phase K 2 NiF 4 structured cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com