Method for manufacturing and integrating multichannel high-sensitive biosensor

A biosensor and integrated method technology, which is applied in the field of silicon nanowire biosensors based on SOI technology, can solve problems such as decreased detection sensitivity, and achieve the effects of reducing false detection rate, high sensitivity, and reducing defective product rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

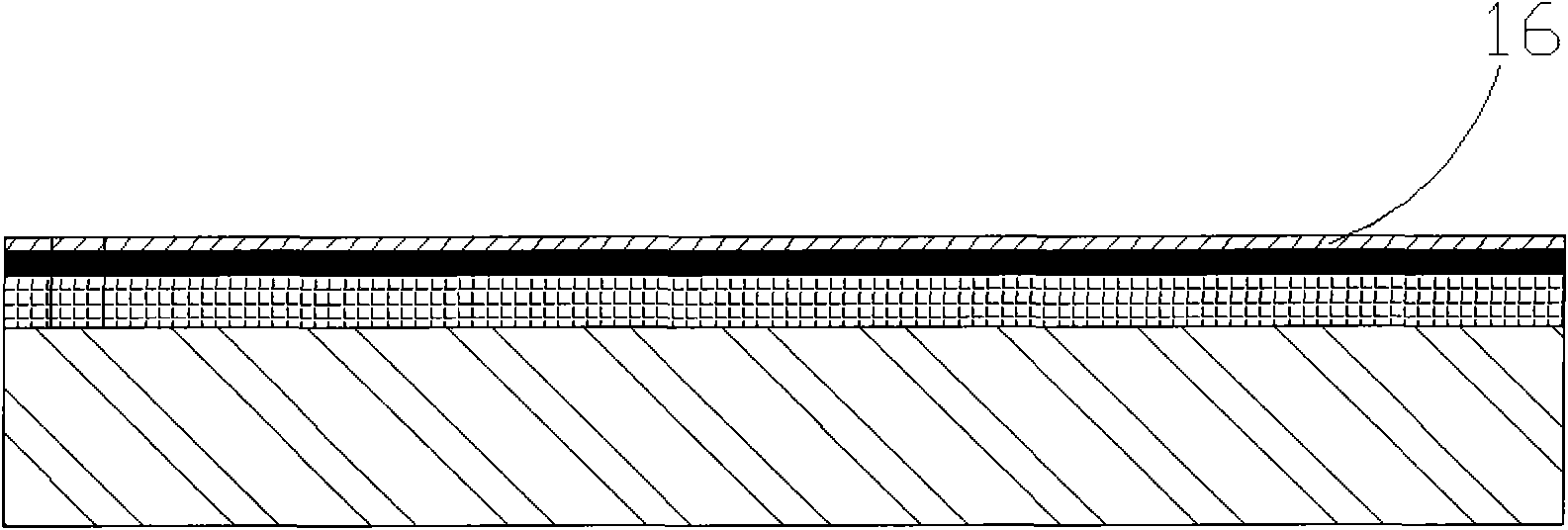

[0048] (1) Silicon nanowire FET field effect transistors are manufactured by top-down method based on SOI silicon wafer:

[0049] 1) Silicon wafer cleaning, first boil the silicon wafer with 7:3 concentrated sulfuric acid and hydrogen peroxide at 60 degrees for 15 minutes, then take out the ultrapure water to rinse, then use 1:3:7 ammonia water and hydrogen peroxide solution to boil for 10 minutes, take out the ultrapure water and rinse ; Next, heat in 1:2:8 hydrochloric acid and hydrogen peroxide aqueous solution at 60°C for 10 minutes, take it out, rinse it with ultrapure water, and dry it with nitrogen; corrode it with 5:1 hydrofluoric acid buffer solution for 5 seconds, take it out, and use ultrapure water Rinse and dry with nitrogen gas; dry in a 100-degree oven for 10 minutes; after cleaning, remove the polluting organic matter and metal ions contained on the surface of the silicon wafer;

[0050] 2) To thin the silicon wafer, first oxidize the silicon wafer with wet oxy...

Embodiment II

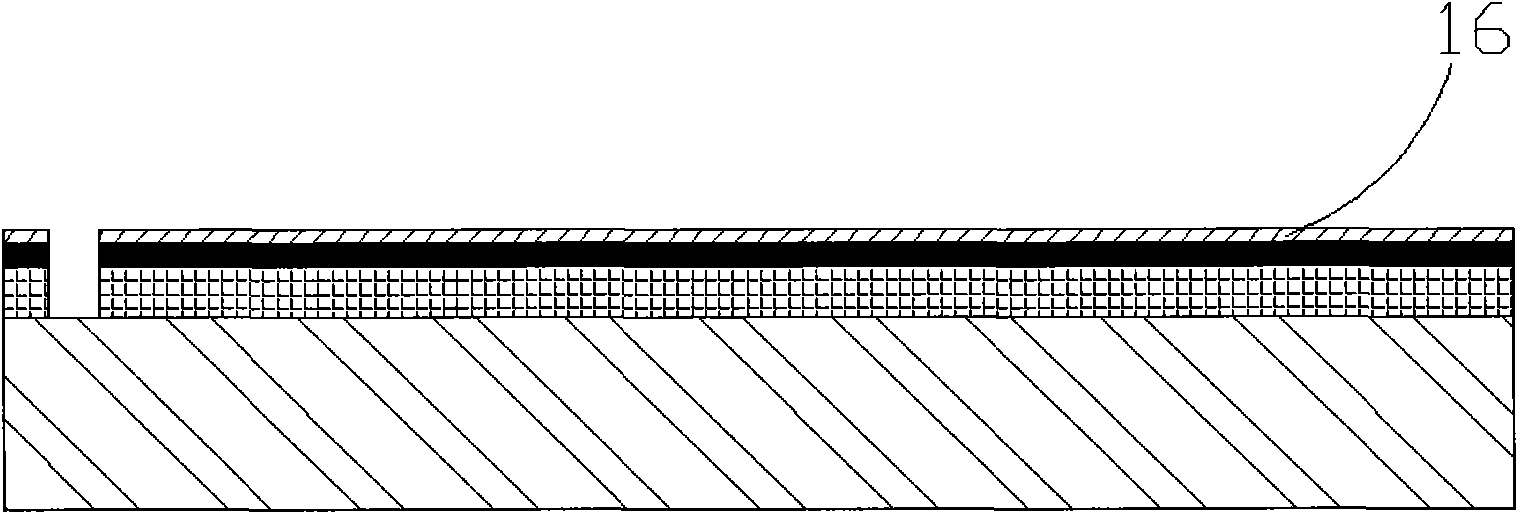

[0066] (1) Silicon nanowire FET field effect transistors are manufactured by top-down method based on SOI silicon wafer:

[0067] 1) Silicon wafer cleaning, first boil the silicon wafer with 7:3 concentrated sulfuric acid and hydrogen peroxide at 60 degrees for 15 minutes, then take out the ultrapure water to rinse, then use 1:3:7 ammonia water and hydrogen peroxide solution to boil for 10 minutes, take out the ultrapure water and rinse , then heated in 1:2:8 hydrochloric acid and hydrogen peroxide aqueous solution at 60°C for 10 minutes, took it out, rinsed it with ultrapure water, dried it with nitrogen, etched it with 5:1 hydrofluoric acid buffer solution for 5 seconds, took it out, and rinsed it with ultrapure water Rinse, blow dry with nitrogen, and dry in a 100-degree oven for 10 minutes. After cleaning, the contaminated organic matter and metal ions contained on the surface of the silicon wafer are removed;

[0068] 2) Thinning of silicon wafers, first oxidize the silic...

Embodiment III

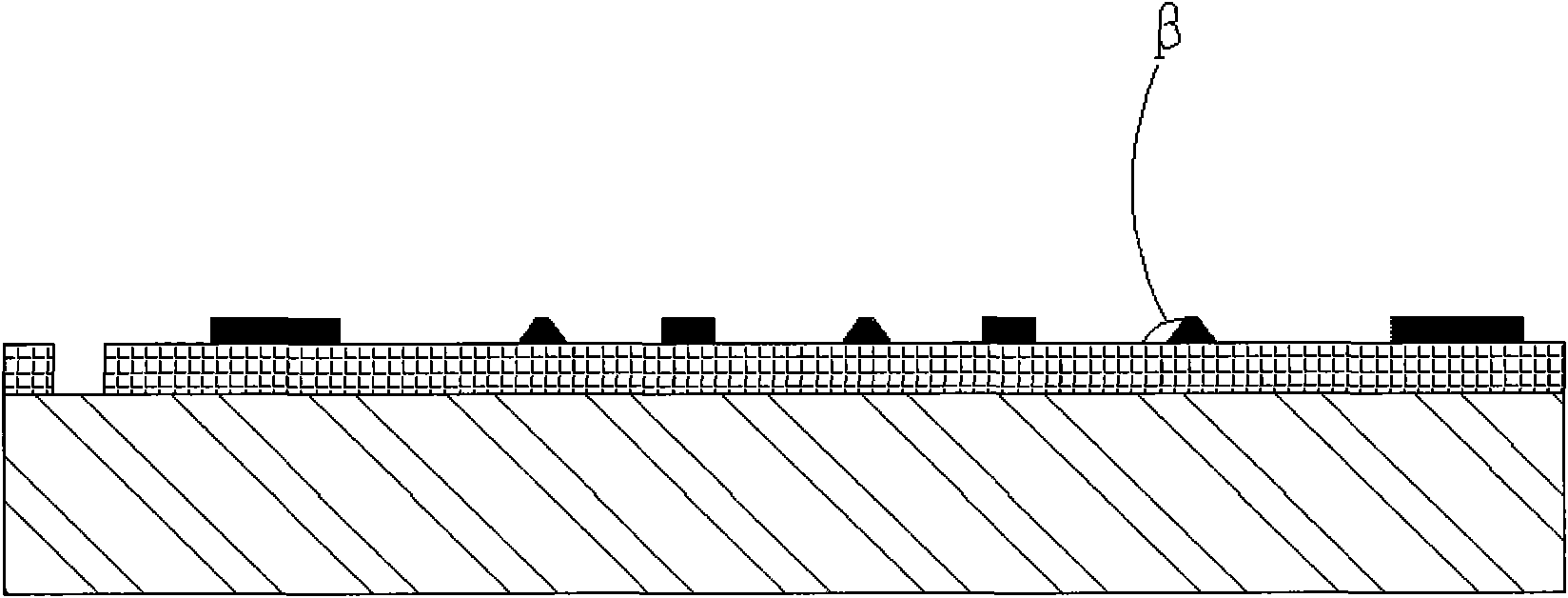

[0086] (1) Silicon nanowire FET field effect transistors are manufactured by top-down method based on SOI silicon wafer:

[0087] 1) Silicon wafer cleaning, first boil the silicon wafer with 7:3 concentrated sulfuric acid and hydrogen peroxide at 60 degrees for 15 minutes, then take out the ultrapure water to rinse, then use 1:3:7 ammonia water and hydrogen peroxide solution to boil for 10 minutes, take out the ultrapure water and rinse , then heated in 1:2:8 hydrochloric acid and hydrogen peroxide aqueous solution at 60°C for 10 minutes, took it out, rinsed it with ultrapure water, dried it with nitrogen, etched it with 5:1 hydrofluoric acid buffer solution for 5 seconds, took it out, and rinsed it with ultrapure water Rinse, blow dry with nitrogen, and dry in a 100-degree oven for 10 minutes. After cleaning, the contaminated organic matter and metal ions contained on the surface of the silicon wafer are removed;

[0088] 2) Thinning of silicon wafers, first oxidize the silic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com