Conductive polymer wave-absorbing material

A technology of conductive polymers and wave-absorbing materials, applied in the field of wave-absorbing materials, can solve the problems of low conductivity, low bandgap width, no literature and patent reports, and no data on wave-absorbing performance, etc., to achieve light weight, thin coating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) A water-soluble polymer polyvinyl alcohol (PVA) solution with a mass concentration of 3% is prepared using a mixture of water and acetonitrile with a volume ratio of 10:1 as a solvent.

[0035]2) Add oxidant iron trichloride to the water-soluble polymer solution prepared in step 1), stir and dissolve, the molar concentration of ferric chloride in polyvinyl alcohol (PVA) aqueous solution is 0.05mol / L, obtain trichloride A mixture of iron and polyvinyl alcohol (PVA).

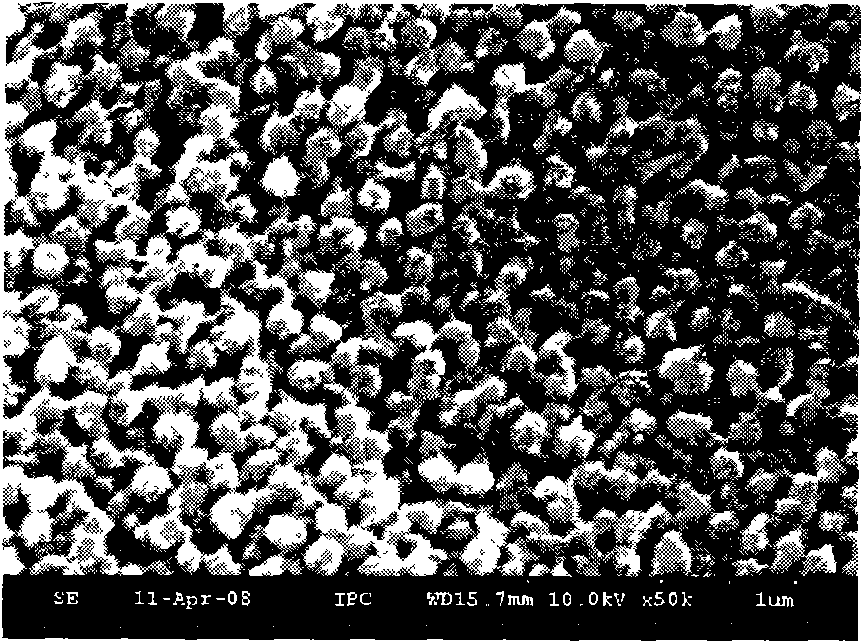

[0036] 3) under stirring conditions, the acid dopant β-naphthalenesulfonic acid is added to the mixed solution obtained in step 2), the molar concentration of the acid dopant β-naphthalenesulfonic acid in the mixed solution is 0.3mol / L, After stirring evenly, add 3,4 dioxyethylthiophene (EDOT), wherein: the molar weight of the added 3,4 dioxyethylthiophene (EDOT) is 0.5 of the ferric chloride molar weight added in step 2). times. Stirring was continued at room temperature for 24 hours to obtain a black...

Embodiment 2

[0040] 1). The mixture of water and acetonitrile with a volume ratio of 5:1 is used as a solvent to prepare a 5% polyvinylpyrrolidone (PVP) solution with a mass concentration.

[0041] 2). Add ammonium persulfate as oxidant in the polyvinylpyrrolidone (PVP) solution prepared in step 1), stir and dissolve evenly, the molar concentration of ammonium persulfate in the solution is 0.1mol / L, and obtain ammonium persulfate and polyethylene Pyrrolidone (mixture of PVP.

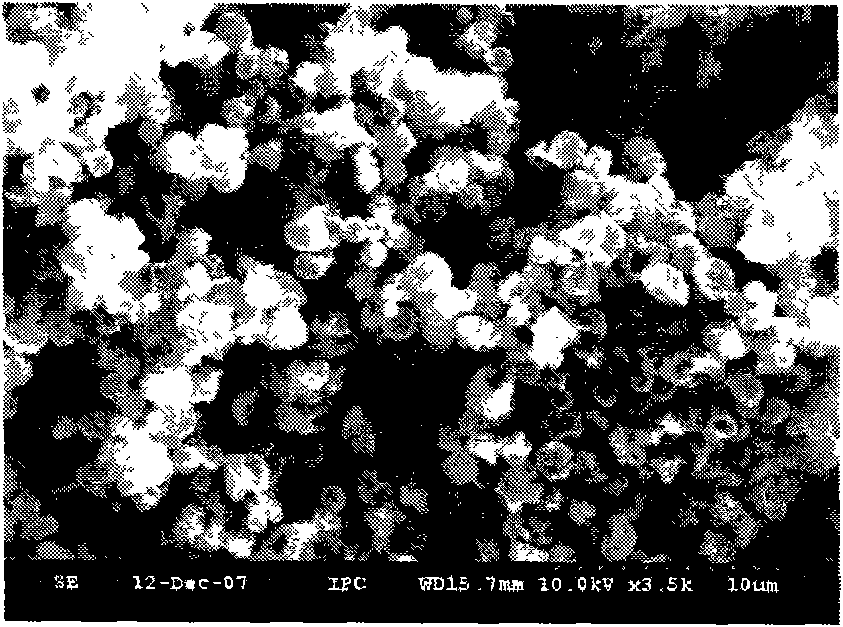

[0042] 3) under agitation, add 3,4 dioxyethylthiophene (EDOT) to the mixed solution obtained in step 2), wherein: the molar weight of the added 3,4 dioxyethylthiophene (EDOT) is the step 2) 2 times the molar amount of ammonium persulfate added in the mixture, and continued to stir and react at room temperature for 72 hours to obtain a black emulsion containing poly(3,4 dioxyethyl)thiophene (PEDOT) hollow microspheres.

[0043] 4) Dry the black emulsion in step 3) at 40° C. to obtain a dark gray blocky solid. The so...

Embodiment 3

[0046] 1) A water-soluble polymer polyvinylpyrrolidone (PVP) solution with a mass concentration of 2% is prepared by using a mixture of water and acetonitrile with a volume ratio of 6:1 as a solvent.

[0047] 2) in the water-soluble macromolecule solution of step 1) adding oxidant chloroauric acid, stirring and dissolving, the molar concentration of chloroauric acid in polyvinylpyrrolidone (PVP) aqueous solution is 0.3mol / L, obtains chloroauric acid and polyvinylpyrrolidone (PVP) aqueous solution A mixture of vinylpyrrolidone (PVP).

[0048] 3) Under stirring conditions, add the acid dopant p-toluenesulfonic acid into the mixed solution obtained in step 2), the molar concentration of the acid dopant p-toluenesulfonic acid in the mixed solution is 0.1mol / L, stir well Finally, add 3,4 dioxyethyl thiophene (EDOT), wherein: the molar amount of 3,4 dioxyethyl thiophene (EDOT) added is 3 times of the molar amount of ferric chloride added in step 2). Stirring was continued at room t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com