Back incident-type TiO* UV detector and preparation method thereof

An ultraviolet light, back-incidence technology, applied in sputtering plating, semiconductor devices, ion implantation plating, etc., can solve the problems of harsh equipment and processing conditions, difficult preparation process, high cost, etc., to achieve high sensitivity, The effect of increasing the effective working area and improving the sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

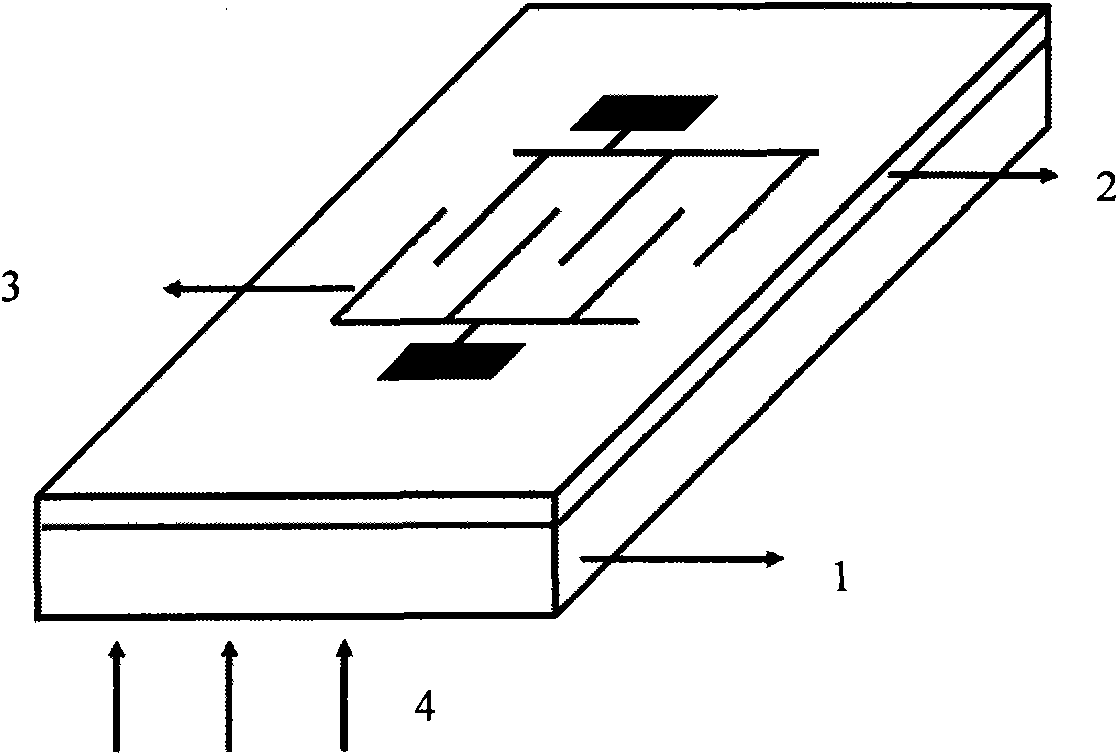

[0029] First, the sol-gel technique was used to grow TiO with a thickness of 0.15 μm on the cleaned quartz substrate. 2 nano film. The specific method is to add 10mL tetrabutyl titanate dropwise to 100mL absolute ethanol under stirring at 1000 rpm at room temperature, then add dropwise 10mL glacial acetic acid, and stir for 60 minutes to obtain a uniform and transparent light yellow solution; 10 mL of deionized water was slowly added dropwise to the above solution at a rate of 1 mL / min, and the stirring was continued for 2 hours to obtain a uniform and transparent light yellow sol, which was left to age for 5 hours. The aged sol was spin-coated on the quartz substrate by spin-coating at a spin-coating speed of 2500 rpm; then the film was sintered in a muffle furnace for 2h at a sintering temperature of 600°C to obtain TiO 2 film. The thickness of the film is about 150 nm.

[0030] In the prepared TiO 2 On the thin film, a photoresist finger structure complementary to the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com