A kind of deposition method of microcrystalline silicon thin film

A technology of microcrystalline silicon thin film and deposition method, which is applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problems of low photoelectric conversion efficiency, lower manufacturing cost, and low growth rate, and achieve large-area low-temperature Preparation, strong absorption properties, uniform grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A 1.7 μm thick amorphous silicon film was deposited on glass by plasma enhanced chemical vapor deposition (PECVD). The discharge gas is Ar, the reaction gas is SiH 4 . The deposition process parameters are: the background vacuum of the deposition chamber is 7×10 -3 Pa, SiH 4 The flow rate is 10sccm, the Ar flow rate is 70sccm, the deposition temperature is ~300°C, the pressure in the reaction chamber is 3.0Pa, the microwave power is 600W, and the deposition time is 6h.

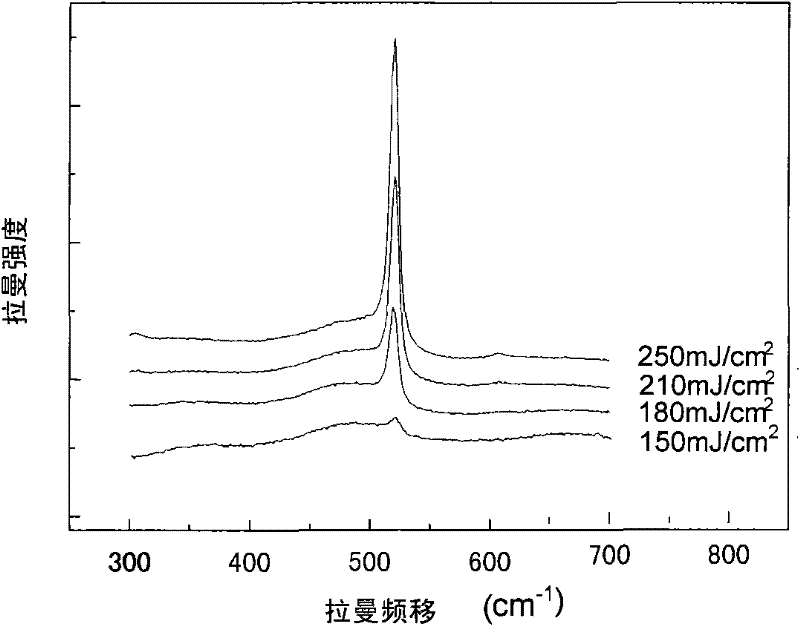

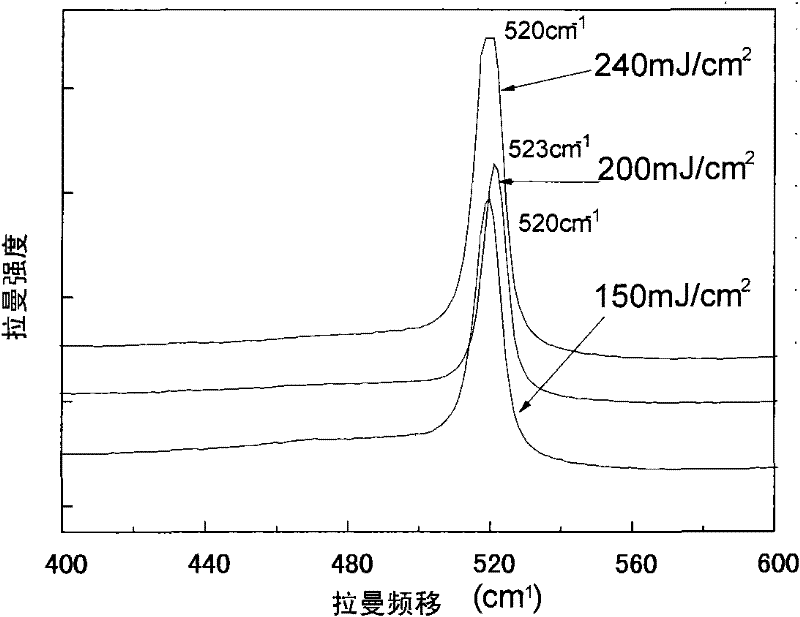

[0027] The pre-deposited a-Si film was cleaned successively with acetone and alcohol solution, dried and fixed on the sample stage, ready for laser surface crystallization. The excimer laser is used as the laser source, the laser is filled with working gas KrF, and the pressure is maintained at 0.5MPa, and argon is introduced as the protective gas of the workpiece, and the pump pulse is gradually adjusted. When the pump pulse with a peak value of 12-20kV is applied to between the discharge electrode...

Embodiment 2

[0033] The difference from Example 1 is:

[0034] A 700nm thick amorphous silicon film was deposited on glass by plasma enhanced chemical vapor deposition (PECVD). The discharge gas is Ar, the reaction gas is SiH 4 . The deposition process parameters are: the background vacuum of the deposition chamber is 7×10 -3 Pa, SiH 4 The flow rate is 10sccm, the Ar flow rate is 70sccm, the deposition temperature is ~300°C, the pressure in the reaction chamber is 3.0Pa, the microwave power is 600W, and the deposition time is 4h.

[0035] The pre-deposited a-Si film was cleaned successively with acetone and alcohol solution, dried and fixed on the sample stage, ready for laser surface crystallization. The excimer laser is used as the laser source, the laser is filled with the working gas ArF, and the pressure is maintained at 0.5MPa, and the argon gas is introduced as the protective gas of the workpiece, and the pump pulse is gradually adjusted. When the pump pulse with a peak value of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| laser pulse width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com