A fully synthetic cutting fluid

A cutting fluid, fully synthetic technology, used in lubricating compositions, petroleum industry, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

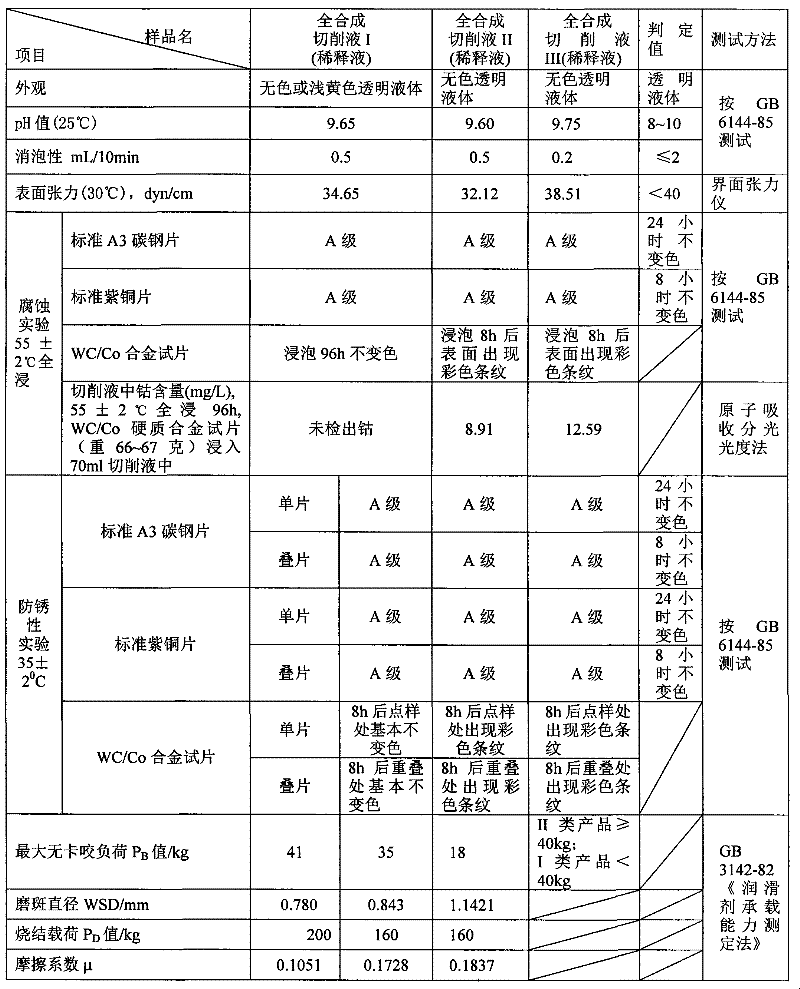

Image

Examples

Embodiment 1

[0019] Synthetic example 1 of embodiment 1 additive

[0020] Weigh 5 grams of OP-10, dissolve it with 30 milliliters of acetone, add 10 milliliters of toluene, raise the temperature to 54-55 ° C, add ammonium persulfate (APS) initiator solution and 5 grams of sodium acrylate dropwise to the reaction system at the same time, drop After the addition is complete, keep the temperature for 5 hours, stop the reaction, remove the organic solvent by distillation, and obtain the self-made additive. The amount of APS accounts for 0.1% of the amount of sodium acrylate.

Embodiment 2

[0021] Synthetic example 2 of embodiment 2 additives

[0022] Weigh 10 grams of TWEEN-80, dissolve it with 30 milliliters of acetone, then add 10 milliliters of toluene, raise the temperature to 54-55 ° C, add APS initiator solution and 7 grams of ammonium acrylate dropwise, after the addition is complete, keep warm for about 5 hours, stop Reaction, the organic solvent is removed by distillation, and the self-made additive is obtained. The amount of APS accounts for 0.2% of the amount of sodium acrylate.

Embodiment 3

[0023] Embodiment 3 Fully synthetic cutting fluid (I) preparation of the present invention

[0024] 15 grams of sodium oleate, 5 grams of OP-10, 15 grams of polyethylene glycol 400, 1.5 grams of borax, 12 grams of additives prepared as in Example 1, 0.2 grams of isothiazolinone, and 0.02 grams of emulsified silicone oil were dissolved in an appropriate amount of In deionized water, adjust the pH value of the above solution to about 9 with 10% sodium hydroxide aqueous solution to obtain a total amount of 100 grams of fully synthetic cutting fluid.

[0025] When using or performing performance tests, dilute fully synthetic cutting fluid I 20 times with deionized water or distilled water before use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com