Method for preparing patterned polymer brush

A technology of polymer brushes and mixed solutions, which is applied in the field of preparation of patterned polymer brushes, can solve the problems of limited use and the influence of surface microstructure stability, and achieves fast initiation speed, simple operation and high graft density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

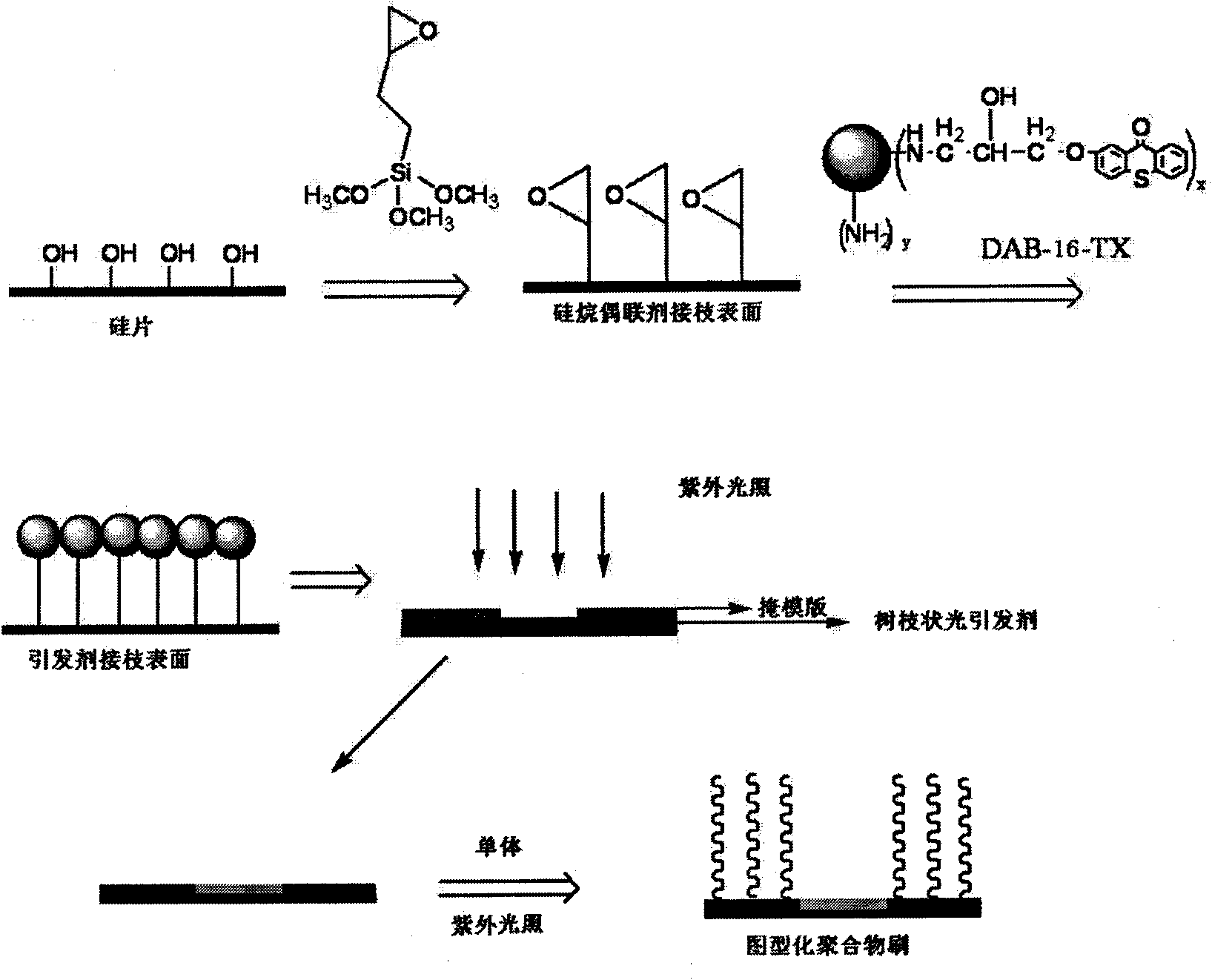

[0020] 1. Substrate treatment

[0021] Boil the silicon substrate in a mixed solution of concentrated sulfuric acid and hydrogen peroxide for 1 hour. The mass ratio of concentrated sulfuric acid and hydrogen peroxide in the mixed solution is 7:3. Then place the substrate in acetone for 30 minutes and rinse it with deionized water. , drying to remove organic matter and impurities on the surface of the substrate.

[0022] 2. Self-assembly of epoxy silane coupling agent

[0023] The cleaned and dried substrate was immersed in a 5 mM toluene solution of 3-glycidyl propoxytrimethoxysilane and allowed to stand for 12 hours. Then, the taken-out substrate was ultrasonically cleaned in toluene and acetone successively, and dried to obtain a silicon chip self-assembled by the epoxy silane coupling agent.

[0024] 3. Initiator DAB-16-TX grafting

[0025] Immerse the self-assembled substrate of the epoxy silane coupling agent in a chloroform solution with a photoinitiator DAB-16-TX con...

Embodiment 2

[0032] 1. Substrate treatment

[0033] Boil the silicon substrate in a mixed solution of concentrated sulfuric acid and hydrogen peroxide for 1.5 hours. The mass ratio of concentrated sulfuric acid to hydrogen peroxide in the mixed solution is 7:3. Then place the substrate in acetone for 20 minutes of ultrasonication. Rinse and dry to remove organic matter and impurities on the surface of the substrate.

[0034] 2. Self-assembly of epoxy silane coupling agent

[0035] The cleaned and dried silicon wafer was immersed in a 5 mM toluene solution of 3-glycidyl propoxytrimethoxysilane and allowed to stand for 12 hours. Then, the silicon chip taken out was cleaned ultrasonically in toluene and acetone successively, and then dried to obtain the self-assembled substrate of epoxy silane coupling agent.

[0036] 3. Initiator DAB-16-TX grafting

[0037] Immerse the self-assembled substrate of the epoxy silane coupling agent in a chloroform solution with a photoinitiator DAB-16-TX conc...

Embodiment 3

[0043] 1. Substrate treatment

[0044] Boil the silicon substrate in a mixed solution of concentrated sulfuric acid and hydrogen peroxide for 2 hours. The mass ratio of concentrated sulfuric acid and hydrogen peroxide in the mixed solution is 7:3. Then place the substrate in acetone for 10 minutes and rinse it with deionized water. , drying to remove organic matter and impurities on the surface of the substrate.

[0045] 2. Self-assembly of epoxy silane coupling agent

[0046] The cleaned and dried silicon wafer was immersed in a 10 mM toluene solution of 3-glycidyl propoxytrimethoxysilane and allowed to stand for 12 hours. Then, the silicon chip taken out was cleaned ultrasonically in toluene and acetone successively, and then dried to obtain the self-assembled substrate of epoxy silane coupling agent.

[0047] 3. Initiator DAB-16-TX grafting

[0048] Immerse the self-assembled substrate of the epoxy silane coupling agent in a chloroform solution with a photoinitiator DAB-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com