Device for recycling waste heat in high temperature steam from rubbish treatment

A high-temperature steam and waste heat recovery technology, applied in the direction of solid waste removal, etc., can solve the problems of excessive energy consumption, multi-energy, air pollution, etc., and achieve the effect of reducing air pollution, saving energy consumption, and reducing heating capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing:

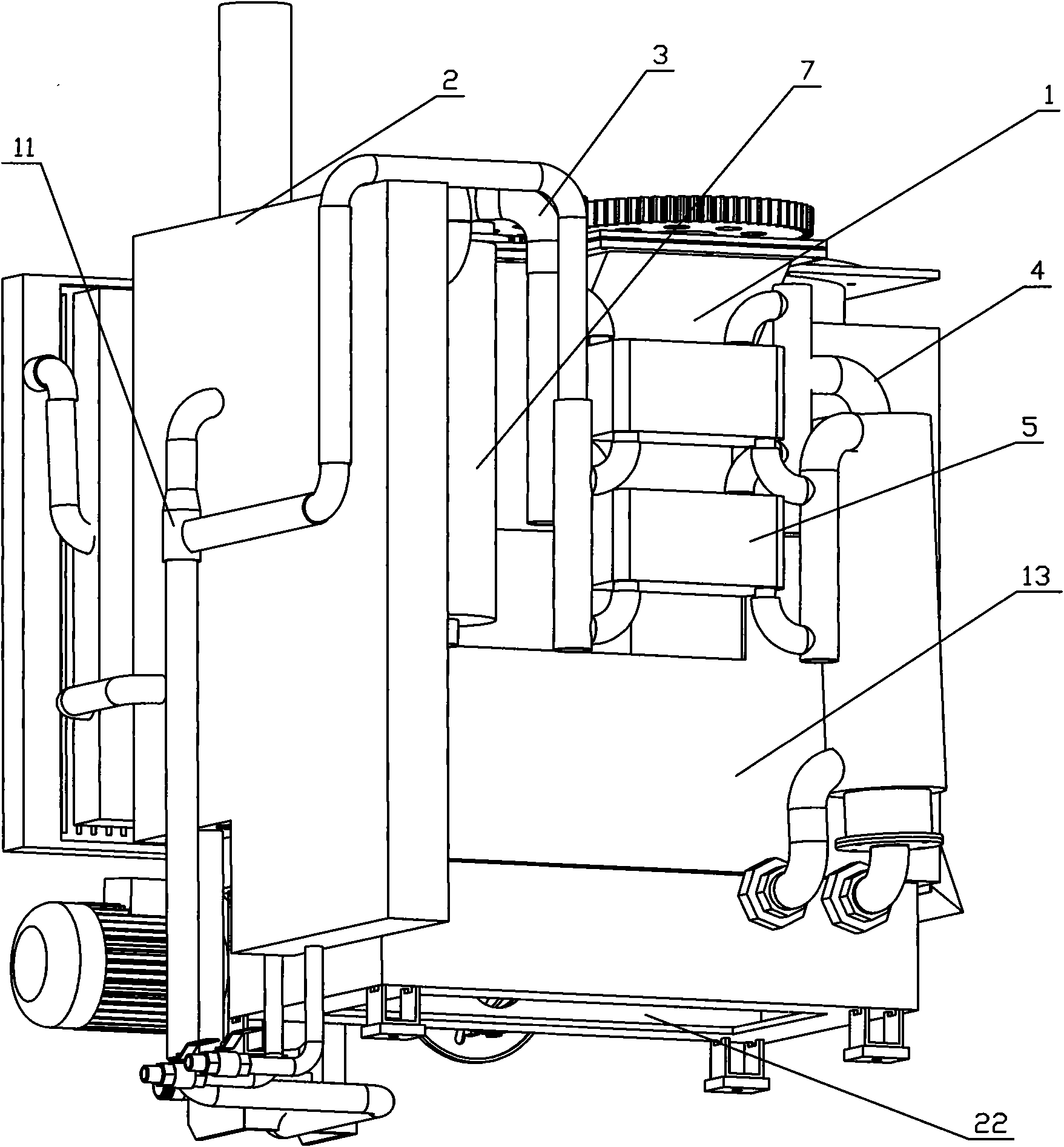

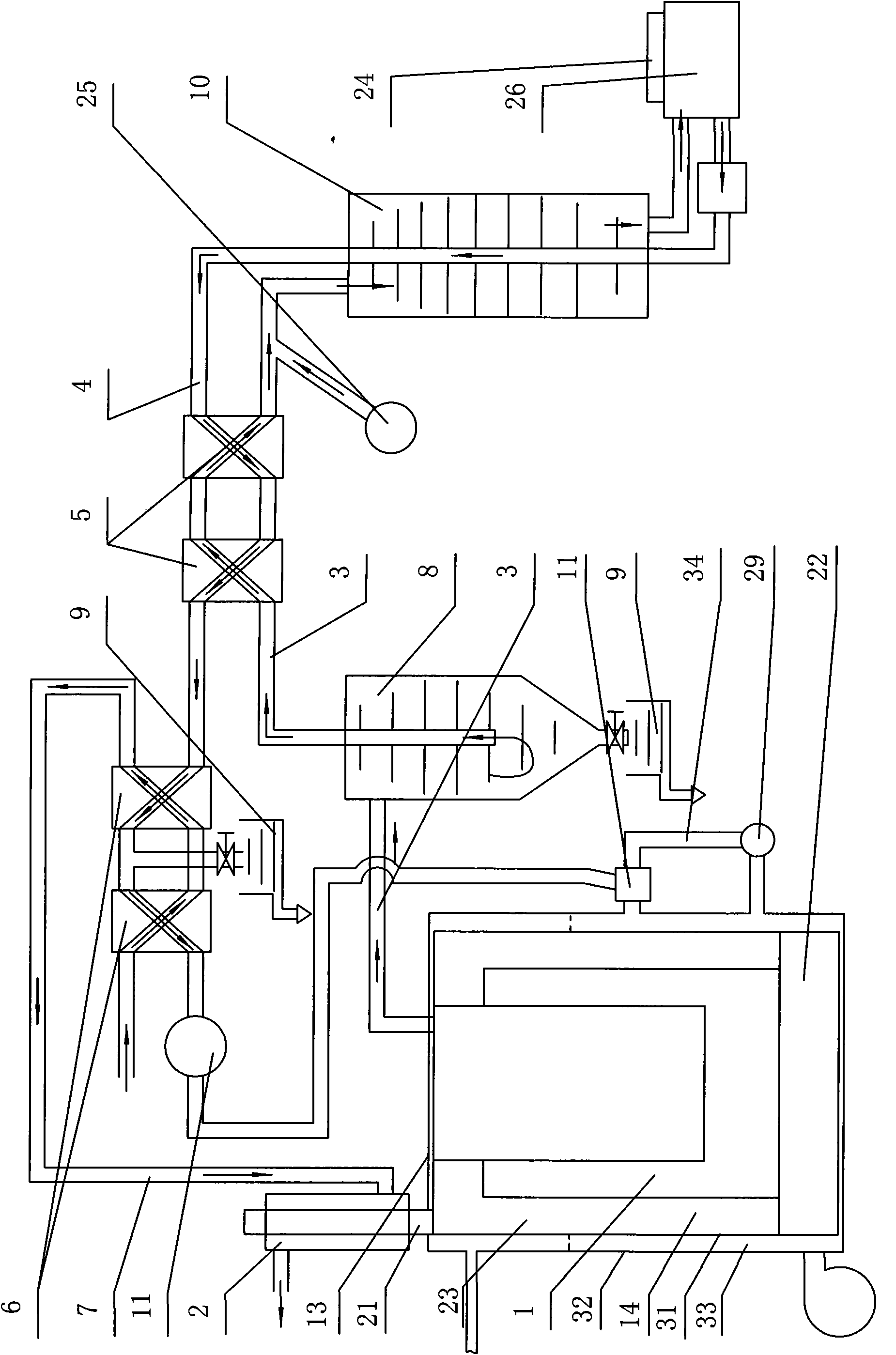

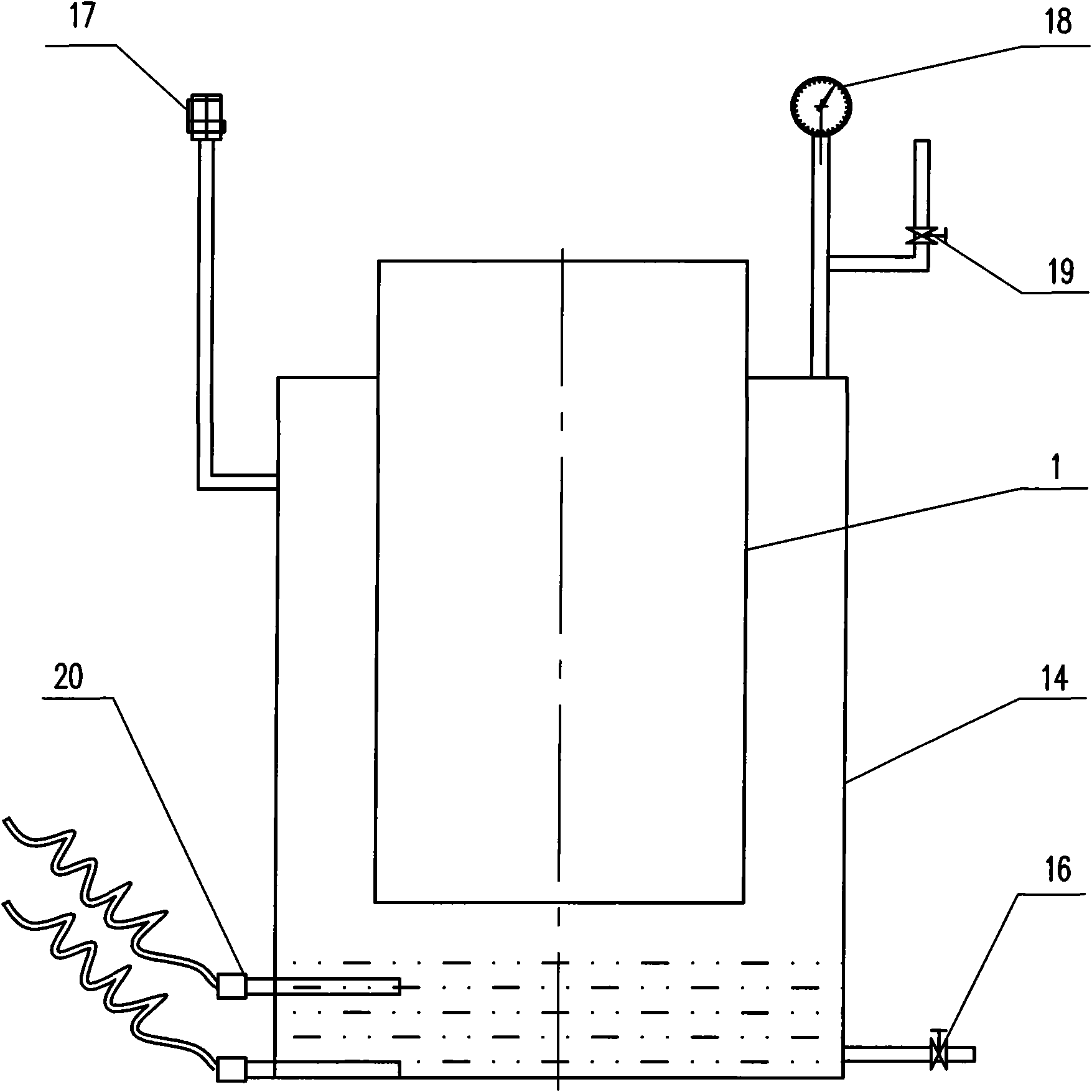

[0026]As shown in the accompanying drawings, a waste heat recovery device for high-temperature steam treated with treated materials includes a treatment tank 1 and a deodorization device. The lower end of the treatment tank 1 is provided with a combustion chamber 22. The heating in the combustion chamber 22 can be heated by a heating plate. Can adopt burner to heat, can also adopt heating plate and burner to heat together, be provided with stirring device in the processing tank 1, the structure of stirring device can be identical with the prior art, this does not go into details, processing tank 1 passes through exhaust channel 3 and The deodorizing device is connected, and it is characterized in that a body of heater 13 is provided, the treatment tank 1 and the combustion chamber 22 are arranged in the body of heater 13, the deodorization device is located in the combustion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com