Method for producing electrodeposited cobalt by non-hydrochloric acid electrolyte

A technology of electrolyte and electrowinning, which is applied to the improvement of process efficiency, photography process, instruments, etc., and can solve the problems of complex process, low metal recovery rate, and increased operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

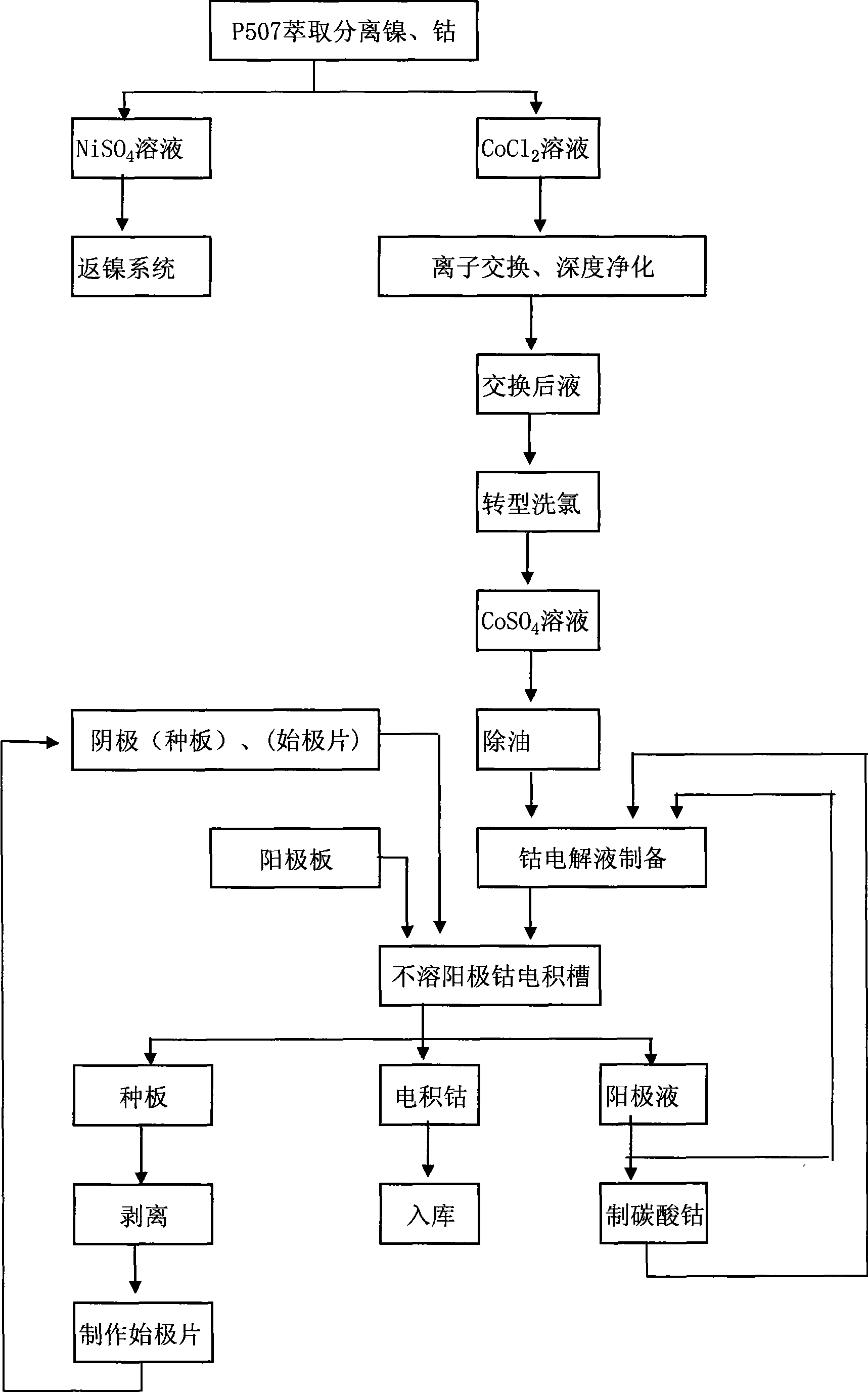

Image

Examples

Embodiment

[0033] The method for producing electrolytic cobalt with the non-hydrochloric acid electrolyte of the present embodiment mainly includes the following steps

[0034] 1) The cobalt raw material is put into a pulverizer for pulverization;

[0035] 2) Grinding in the grinding machine;

[0036] 3) Put the ground fine powder into the leaching tank for oxidative leaching to obtain the pre-extraction solution;

[0037] 4) Use chemical methods to remove metal and non-metal impurities, and remove impurities such as calcium and magnesium;

[0038] 5) Solvent extraction: extract with P204 extractant to obtain CoCl 2 solution;

[0039] 6) Resin exchange is used to remove impurities for deep purification.

[0040] 7) Extraction transformation

[0041] CoCl 2 After the solution is separated from nickel Ni and cobalt Co by extractant P507, cobalt is still in the form of CoCl 2 In order to ensure the environmental quality of the electrowinning process, it must be converted to a non-hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com