Process and device for coating steel strip through ECR microwave plasma chemical vapor deposition

A technology of chemical vapor deposition and microwave plasma, applied in the direction of gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of not seeing continuous strip steel coating, not finding, etc., to avoid pollution, ionization degree The effect of high and low substrate temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

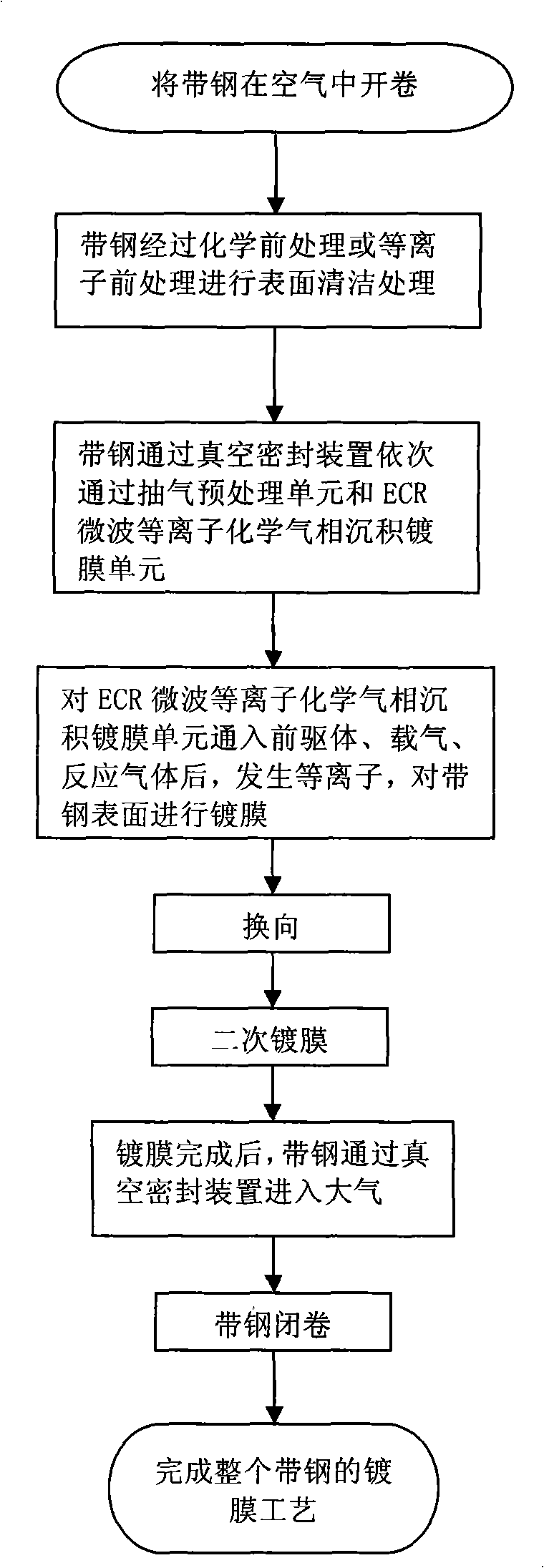

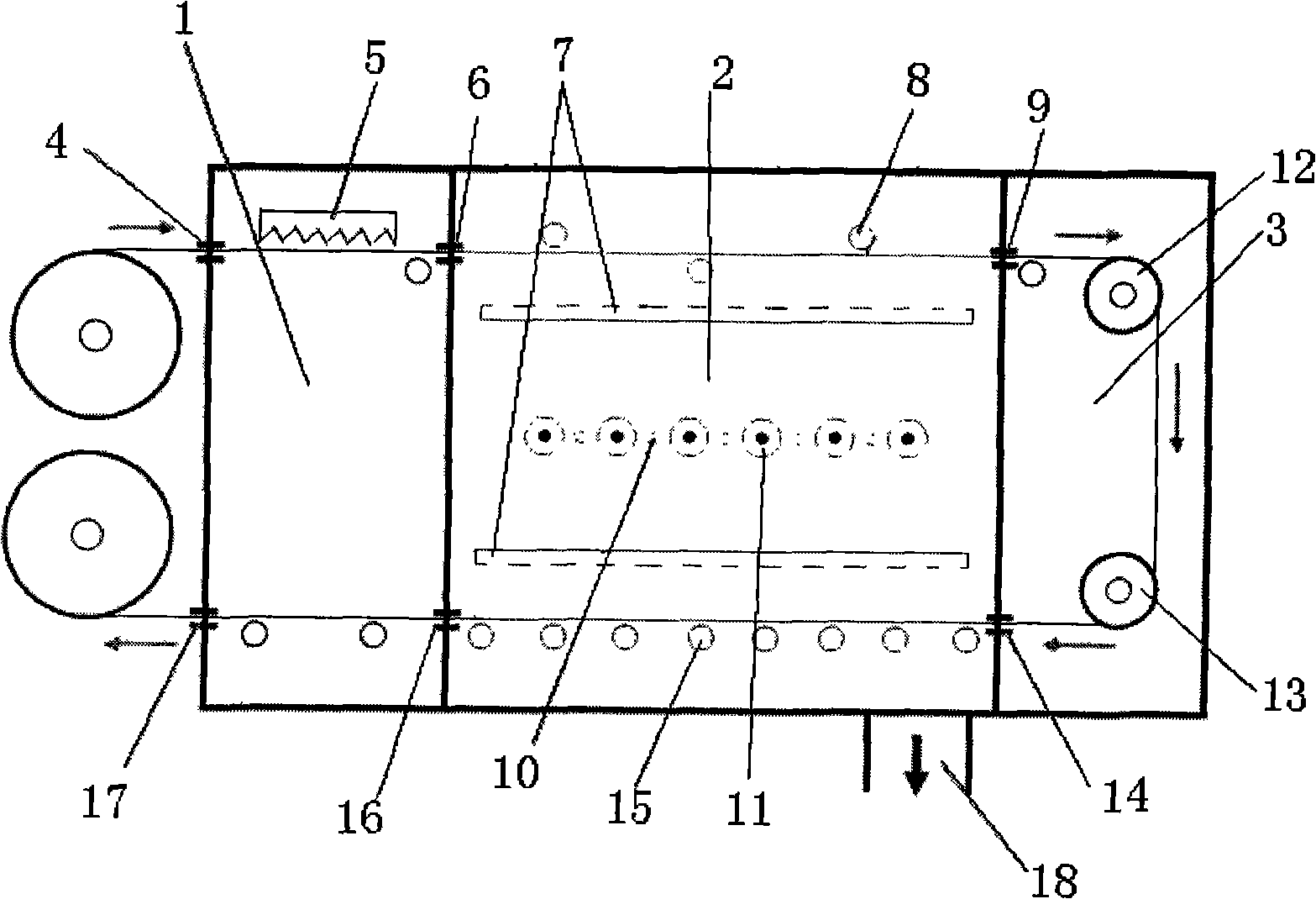

Method used

Image

Examples

Embodiment 1

[0054] Embodiment one. Cold-rolled steel strip is coated with SiO 2

[0055] In this example, SiH4 is selected as the precursor, oxygen is passed through, and SiO2 film is deposited in the ECR microwave plasma chemical vapor deposition coating unit.

[0056] The ratio of SiH4 / O2 is 8 / 24, and Si:O is closest to 1:2 at this flow rate.

[0057] The cold-rolled sheet passes at 20m / min, which can achieve 50-100nm SiO 2 coating products.

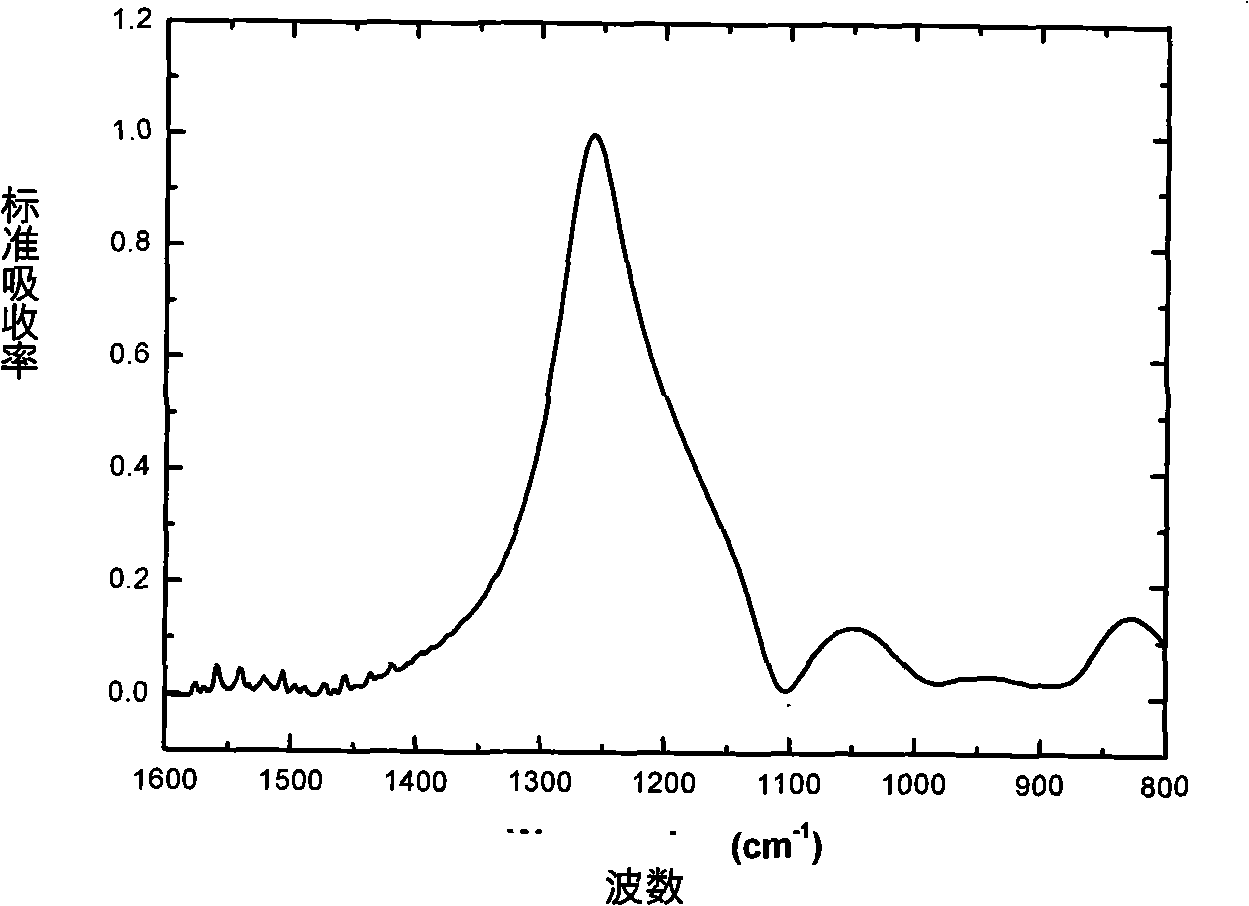

[0058] When the width of the cold-rolled sheet is in the range of 300mm, the fluctuation of the film thickness is within 3%. The deposited SiO 2 Thin film structure diagram (FTIR diagram) such as image 3 As shown, it can be seen that what is deposited is SiO 2 film.

Embodiment 2

[0059] Embodiment 2. Galvanized steel coil coated with SiO 2

[0060] In this example, choose SiH 4 As a precursor, oxygen is introduced to deposit SiO in the ECR microwave plasma chemical vapor deposition coating unit 2 film.

[0061] SiH 4 / O 2 The ratio is 8 / 24, and Si:O is closest to 1:2 at this flow rate.

[0062] 50-100nm SiO can be achieved when the galvanized sheet passes through at 20m / min 2 coating products.

[0063] When the width of the cold-rolled sheet is in the range of 300mm, the fluctuation of the film thickness is within 3%. Its film structure is as Figure 4 and Figure 5 As shown, it can be seen that what is deposited is SiO 2 film.

Embodiment 3

[0064] Embodiment three. Plating TiO on stainless steel coils 2

[0065] In this example, titanium isopropoxide TIPT (Ti(O-i-C 3 h 7 ) 4 )) As a precursor, oxygen is introduced to deposit TiO in the ECR microwave plasma chemical vapor deposition coating unit 2 film.

[0066] TIPT is heated to 100 degrees, through argon, into the coating chamber; when the ratio of TIPT and oxygen is 1:2. Generate plasma for coating. Stainless steel plate passes at 20m / min, 50nm TiO can be achieved 2 coating products.

[0067] It can be seen from the above examples that surface technology will be the focus of the next steel technology research and development, especially the best process for realizing "personalized products". The user's demand for performance and the pressure of environmental protection make the vacuum coating technology as "the next generation of continuous strip steel coating technology" has attracted great attention, and has become a worldwide research and development...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com