Preparation method for titanium dioxide group catalyst carrier

A technology of titanium dioxide and carrier, which is applied in the field of preparation of titanium dioxide-based catalyst carrier, which can solve the problems of reduced mechanical strength of catalyst carrier and unfavorable catalyst life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

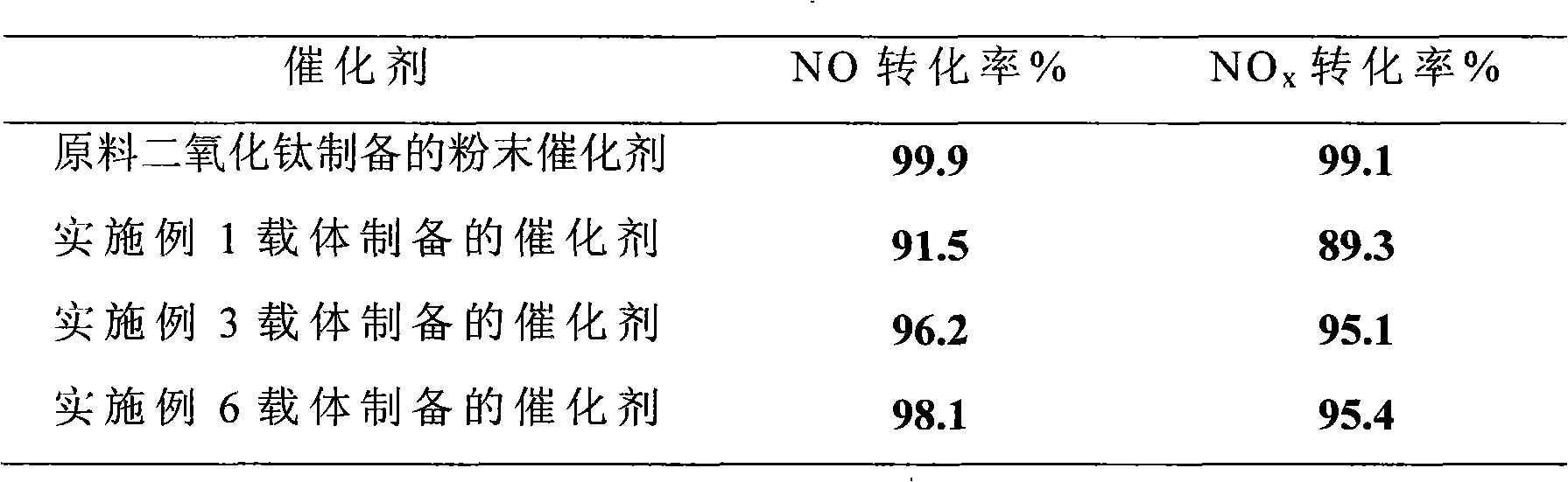

Examples

Embodiment 1

[0034] Example 1: Take 1000g of titanium dioxide prepared in the preparation example, crush the titanium dioxide powder until the particle size is less than 325 mesh, add 230g of bentonite, 60g of sodium carboxymethyl cellulose, and 25g of aluminum stearate, mix and grind evenly, and then add 30g of Glycerin, 10g of 65% concentrated nitric acid, 300g of distilled water are mixed and kneaded into mud in a kneader. The mud is stale for 12 hours at a temperature lower than 25°C, and extruded into a cylindrical or clover-shaped mud stick with a diameter of Ф4 through an extruder. After the mud strips were left at room temperature for 12 hours, they were cut into 2mm long column grains or clover. Dry the wet support at 60°C in an air atmosphere for 12 hours, and then burn at 500°C for 6 hours to obtain the desired catalyst support. The carrier has a lateral compressive strength of ~25N / mm and a specific surface area of ~85m 2 / g.

Embodiment 2

[0035] Embodiment 2: get the metatitanic acid 1000g (calculated as titanium dioxide) prepared by the preparation example, the metatitanic acid powder is pulverized to a particle size less than 325 mesh, add 230g kaolin, 60g methylcellulose, 25g aluminum stearate, After mixing and grinding evenly, add 30g of glycerin, 10g of 65% concentrated nitric acid, and 250g of distilled water, and mix and knead in a kneader to form a slurry. The mud is stale for 12 hours at a temperature lower than 25°C, and extruded into a cylindrical or clover-shaped mud stick with a diameter of Ф4 through an extruder. After the mud strips were left at room temperature for 12 hours, they were cut into 2mm long column grains or clover. Dry the wet support at 60°C in an air atmosphere for 12 hours, and then burn at 500°C for 6 hours to obtain the desired catalyst support. The support has a lateral compressive strength of ~32N / mm and a specific surface area of ~85m 2 / g.

Embodiment 3

[0036]Example 3: Take 1000 g of titanium dioxide prepared in the preparation example, grind the titanium dioxide powder to a particle size of less than 325 mesh, add 20 g of silicon dioxide, 60 g of methyl cellulose, and 25 g of aluminum stearate, mix and grind evenly. Another 100g of pseudo-boehmite (PA98 type, produced by Jinling Petrochemical Alkylbenzene Factory) was taken, mixed with 200g of 0.5M nitric acid to form a slurry, and added to the above mixed powder. Then add 30g of glycerin, 10g of citric acid, and 100g of distilled water, mix and knead in a kneader to form a slurry. The mud is stale for 12 hours at a temperature lower than 25°C, and extruded into a cylindrical or clover-shaped mud stick with a diameter of Ф4 through an extruder. After the mud strips were left at room temperature for 12 hours, they were cut into 2mm long column grains or clover. Dry the wet support at 60°C in an air atmosphere for 12 hours, and then burn at 500°C for 6 hours to obtain the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com