Electrode wire for wire electric discharging, method for manufacturing the electrode wire, and apparatus for manufacturing bus line thereof

A technology of wire discharge machining and manufacturing method, which is applied in the field of improved wire discharge machining electrode wires, can solve the problems of increased manufacturing costs and complicated procedures, and achieve the effects of reduced production, good discharge performance, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

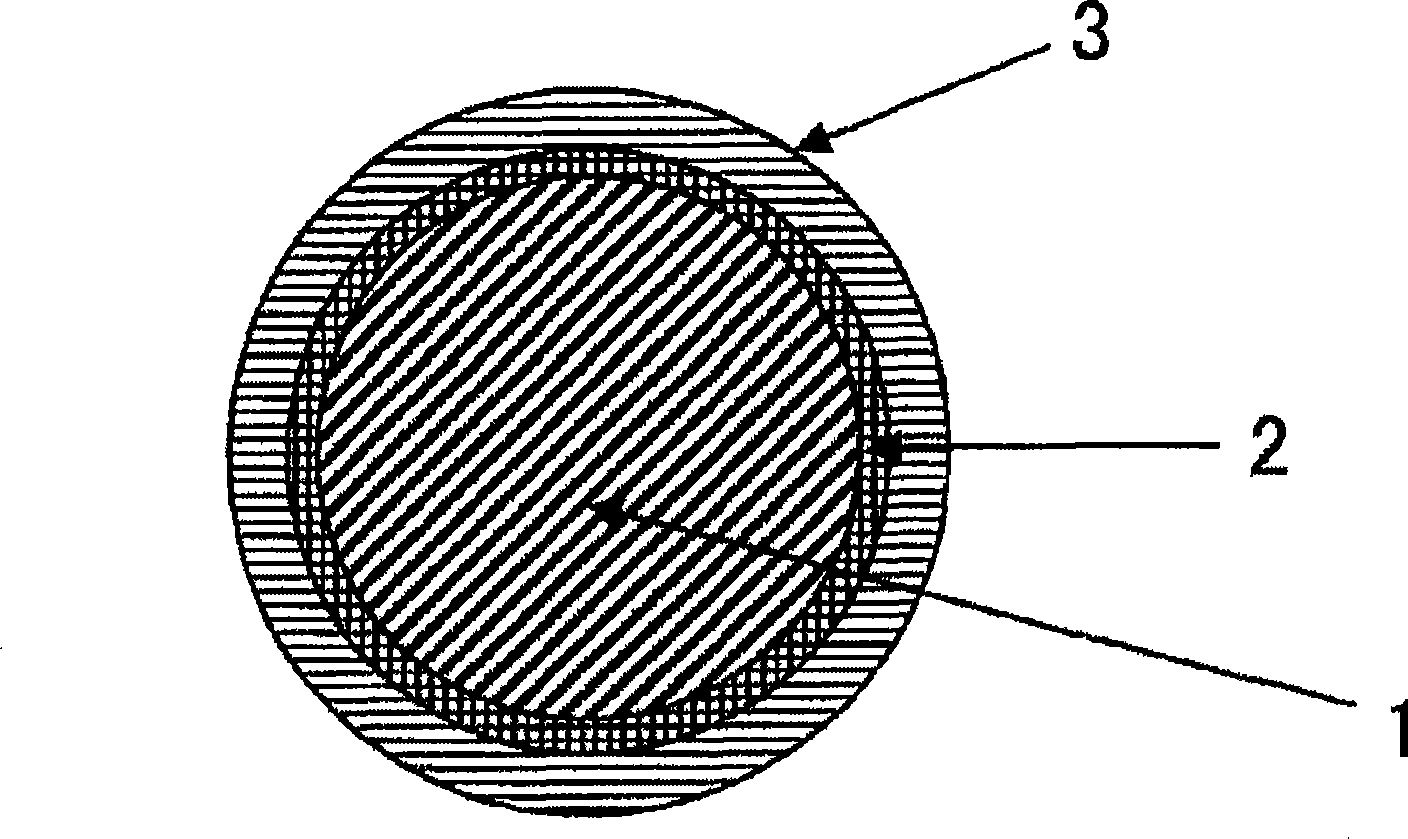

[0064] The first embodiment (Example No1 to No4)

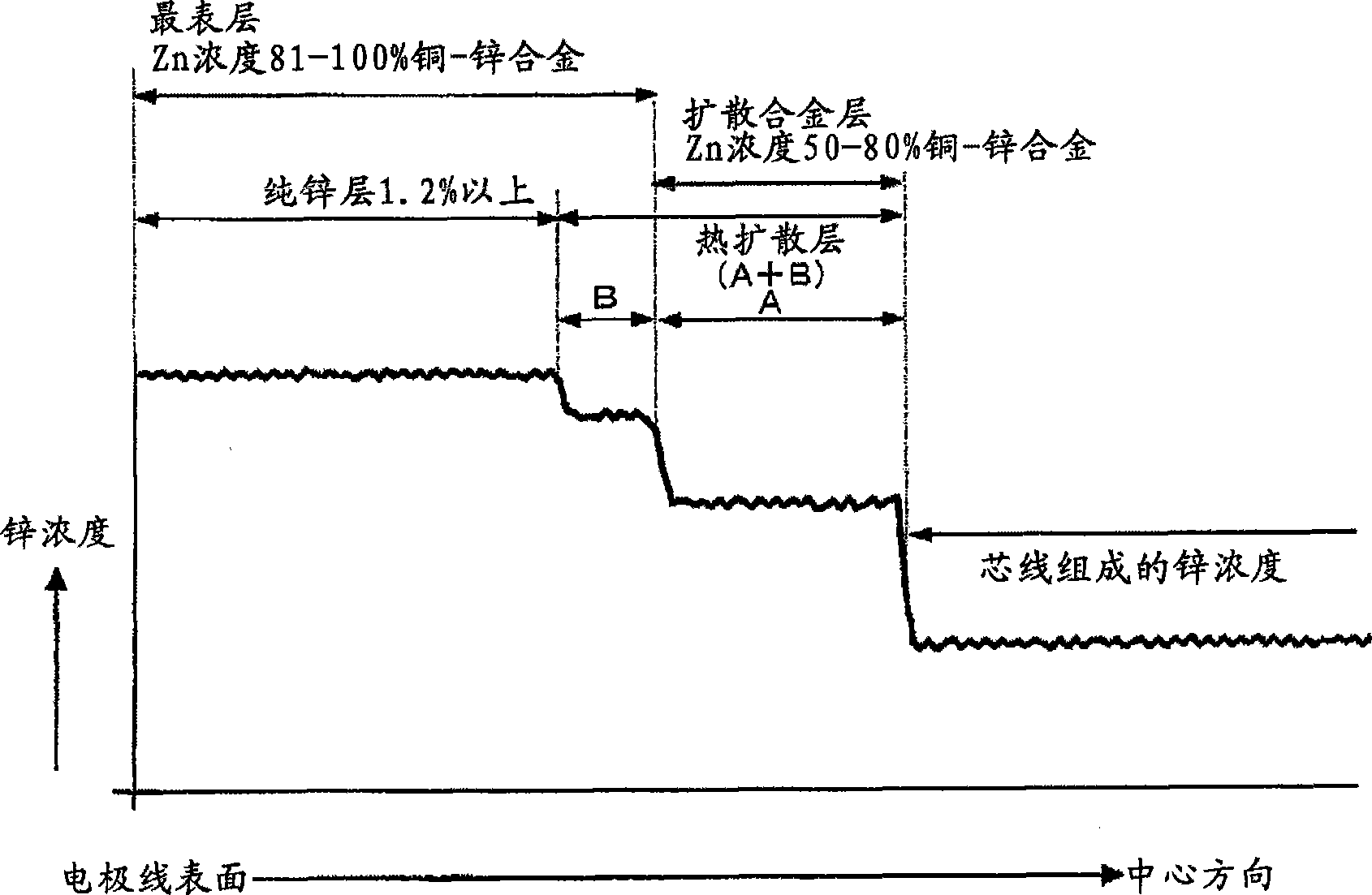

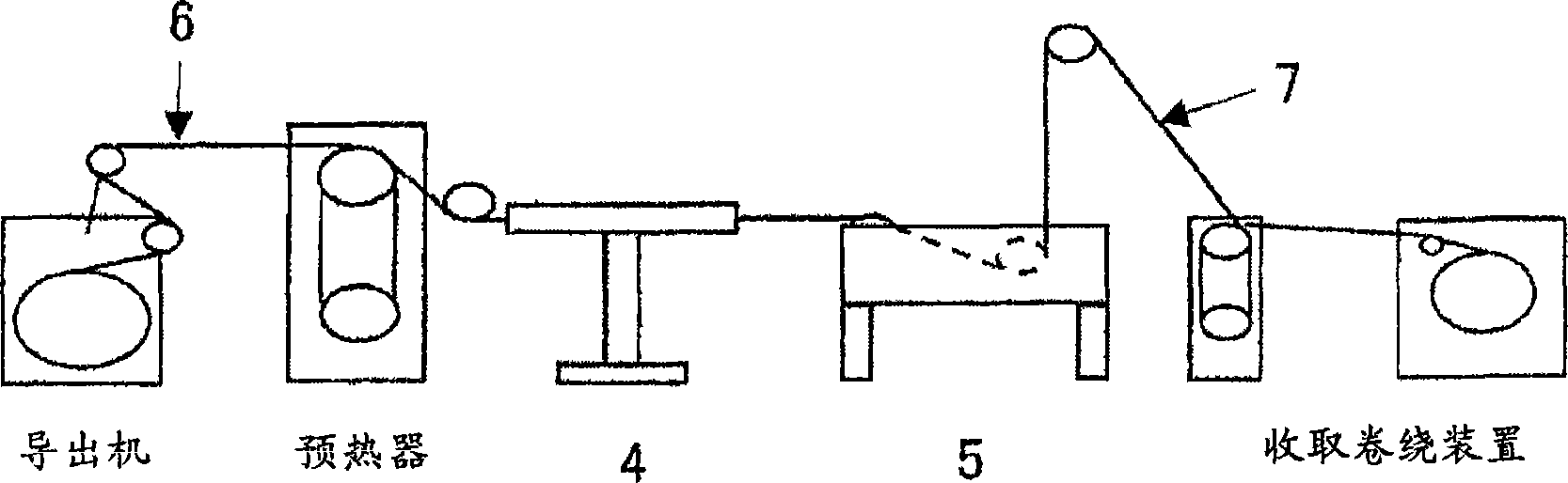

[0065] 65 / 35 brass wire (copper 65% by weight / zinc 35% by weight) with a wire diameter of 1.2 mm through melting, casting, and wire drawing processes is used as the core wire 6, and the image 3 The pickling, water washing, and flux tank 4 that constitute a part of the hot-dip coating apparatus are shown to wash the surface, pass it through the coating tank 5 that maintains pure zinc at 460°C, and then pass it through the coating tank 5 Pull vertically and perform blowing treatment, thereby forming a copper-zinc alloy layer by mutual thermal diffusion at the interface where the brass wire and zinc are in contact, and for the purpose of studying, make the upper layer of the copper-zinc alloy layer The range of the immersion time of the pure zinc layer was changed to four examples of 0.5 second, 0.7 second, 1.0 second, and 1.2 seconds to manufacture the plated bus bar 7 of the electrode wire.

[0066] For blowing treatment, in ...

no. 2 Embodiment

[0069] The 2nd embodiment (embodiment No5 and No6)

[0070] Electrode wires with a diameter of 0.25 mmφ were produced under the same conditions as in the first embodiment above, except that the temperature of the hot-dip coating tank was 440° C. and the immersion time was 0.5 second and 1 second.

no. 3 Embodiment

[0071] The 3rd embodiment (embodiment No7 and No8)

[0072] Electrode wires with a diameter of 0.25 mmφ were produced under the same conditions as in the first embodiment above, except that the temperature of the hot-dip coating tank was set to 500° C. and the immersion time was set to 0.5 second and 1 second.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com