Method for extracting medlar polysaccharide

An extraction method and technology of wolfberry polysaccharide, which are applied in the field of high-efficiency and energy-saving extraction of wolfberry polysaccharide, can solve the problem that the extraction of active ingredients that do not involve fresh biological materials and the ultra-fine pulverization function using microwaves, the inability to dry wolfberry fruit in time, and the impact on wolfberry fruit Quality and safety problems, to achieve the effect of solving heavy labor and energy waste, reducing energy consumption, and saving extraction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

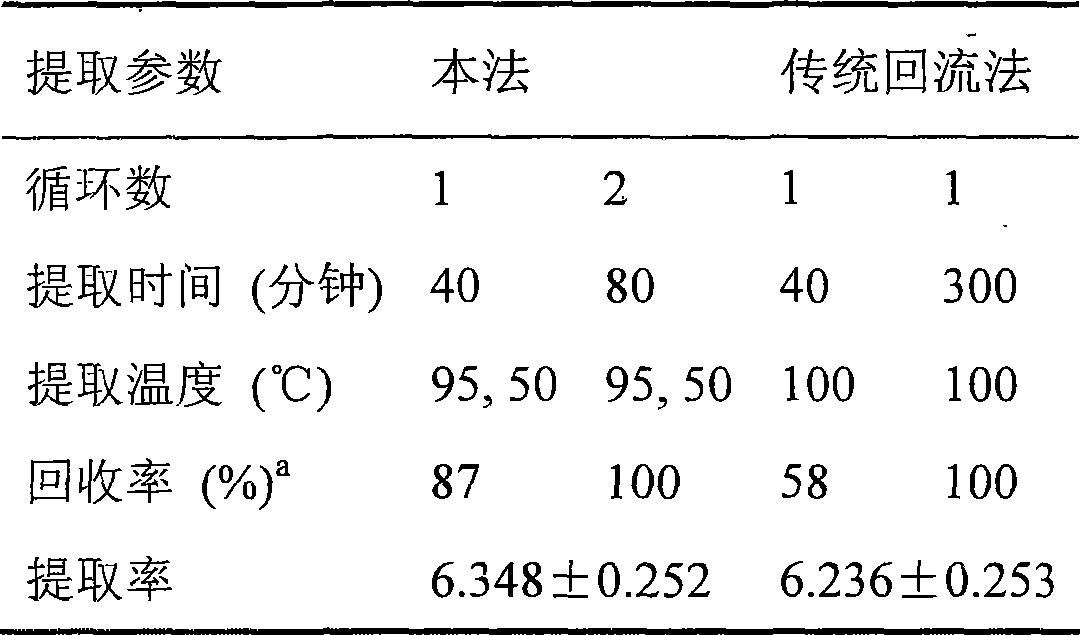

Examples

Embodiment 1

[0021] A kind of operation step of extracting polysaccharide from fresh medlar is as follows:

[0022] 1. Extract fully mature wolfberry;

[0023] 2. Use a refiner to grind the fresh wolfberry into a homogenate, which can be repeatedly refined once or twice or three times or four times according to the fineness of the homogenate;

[0024] 3. Pour fresh wolfberry homogenate into the container. The bottom of the container should be made of glass plate, and the microwave will act on the homogenate through the glass from the bottom; or the microwave will act on the homogenate from the top or side, and the corresponding microwave will pass through The surface is made of glass material;

[0025] 4. Microwave treatment until the homogenate temperature is 50 degrees Celsius or 60 degrees Celsius or 70 degrees Celsius or 80 degrees Celsius or 90 degrees Celsius or 100 degrees Celsius, and the boiling time lasts for 10 minutes or 20 minutes or 30 minutes or 40 minutes or 50 minutes or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com