Polyester resin composition and light reflector

A technology of polyester resin and light reflector, which is applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., and can solve the problems of not being able to continuously obtain moldings, impairing reflective metal surfaces, and rising mold temperature gas , to achieve the effect of excellent surface and light reflectivity, reduction of suppression characteristics, and excellent surface appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~12、 comparative example 1~9

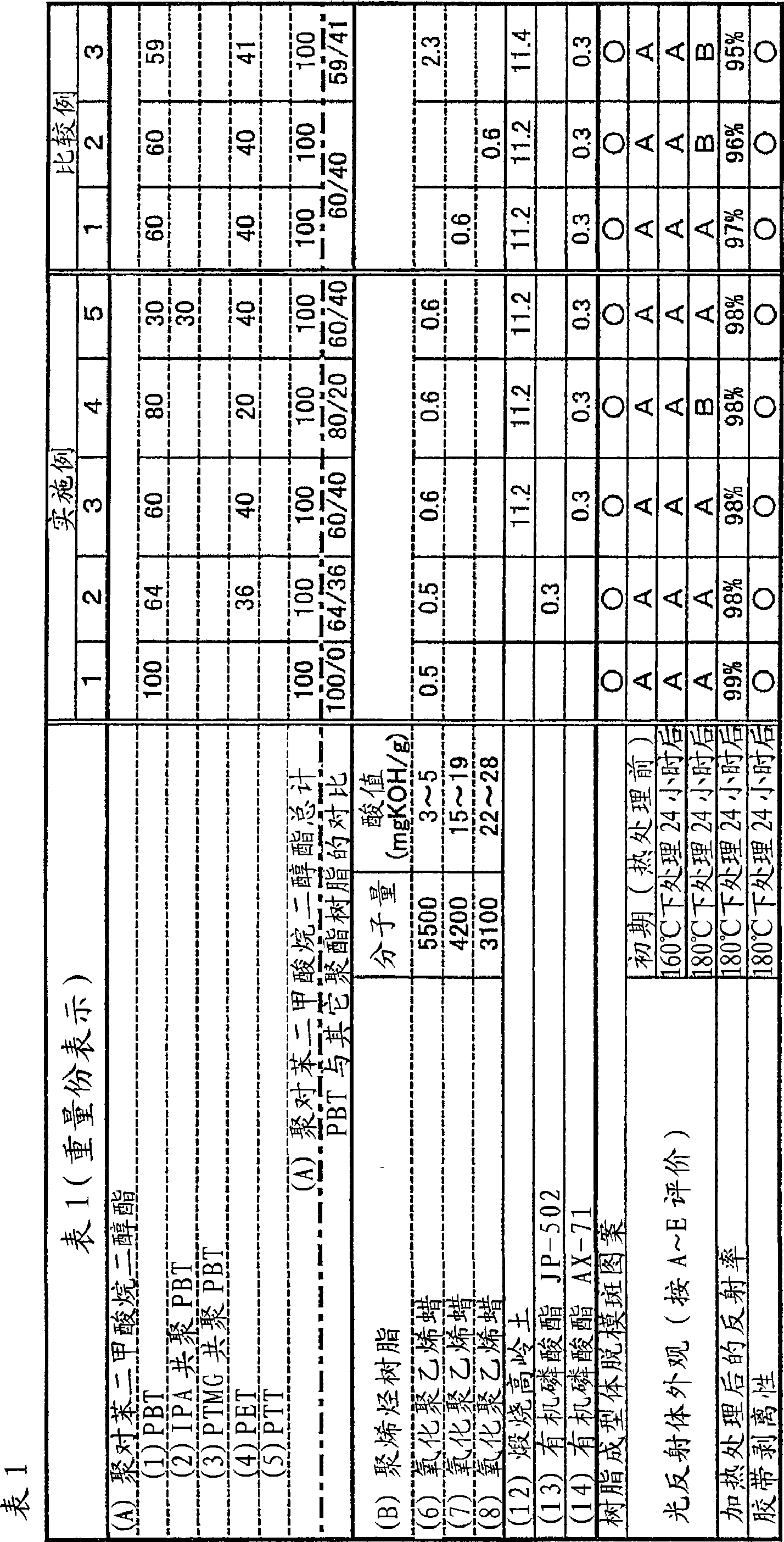

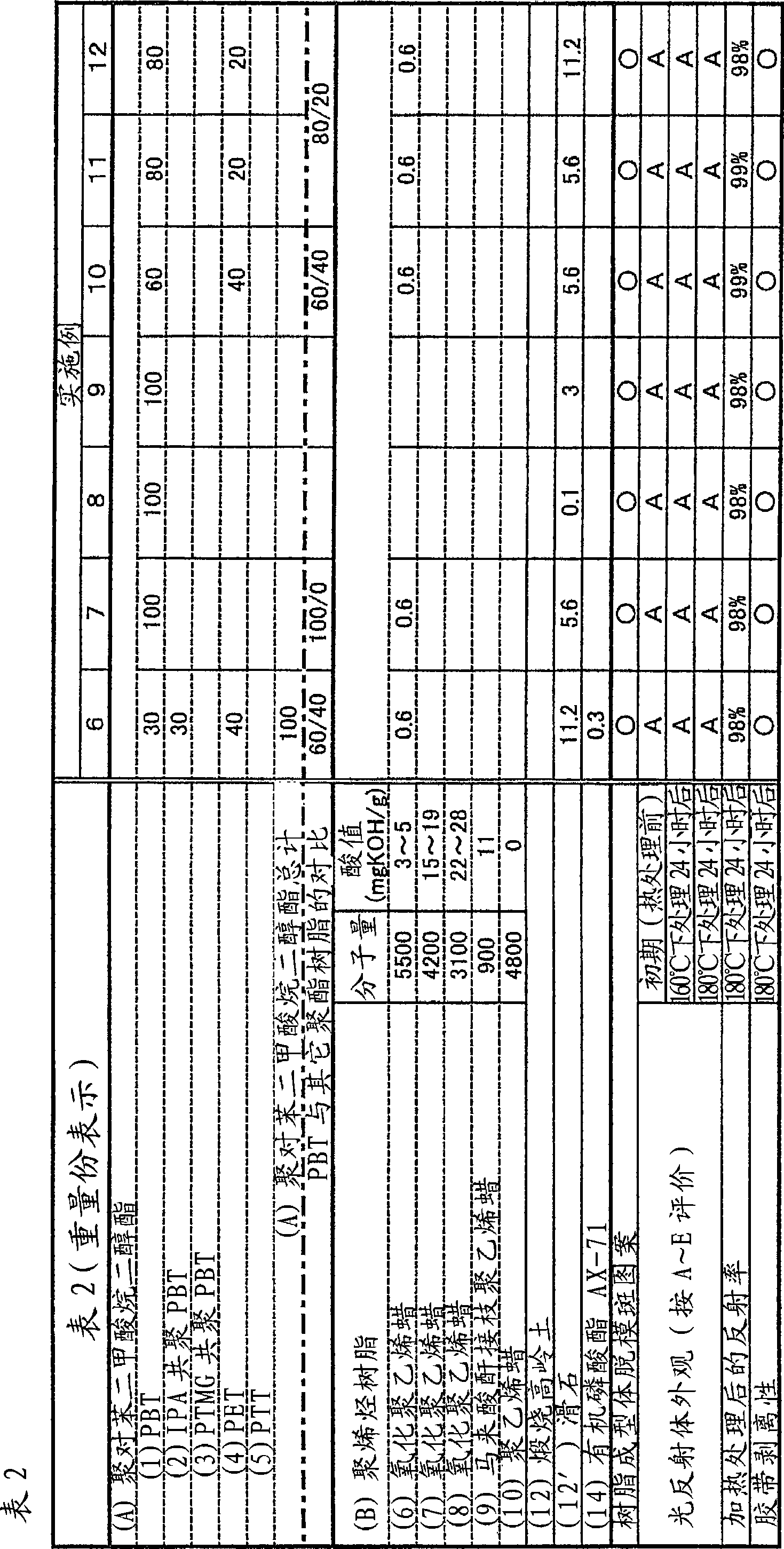

[0154] Fully dry mix polyester resin, modified polyolefin resin, particulate filler and other additives according to the composition in Table 1, and then use a twin-screw extruder whose temperature is set at 250°C to extrude at a speed of 15kg / hour Granulated.

[0155] The obtained pellets were dried at 120°C for 6 hours before injection molding, using an injection molding machine with a clamping pressure of 75 tons, a molding temperature of 265°C, and a mirror mold with a molded body shape of 100mm×100mm×3mm. Molding was performed at 110° C. to obtain a resin molded body. The releasability during injection molding is good, and it can be easily taken out from the molded body.

[0156] Aluminum was vapor-deposited on the surface of the obtained resin molded body without primer treatment so that the thickness of the aluminum film was 140 nm, and an aluminum-deposited light reflector was obtained. In addition, using the above-mentioned pellets, an ISO test piece was molded by a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com