Expansion type flame-retardant coatings glue and use thereof in textile finishing

A flame retardant coating and fabric finishing technology, applied in fiber type, fiber treatment, plant fiber, etc., can solve the problems of loss or degradation of flame retardants, fabrics that cannot be washed, and easy decline in flame retardant performance, so as to improve the durability Washable, realizes multi-functionality, and has good washing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

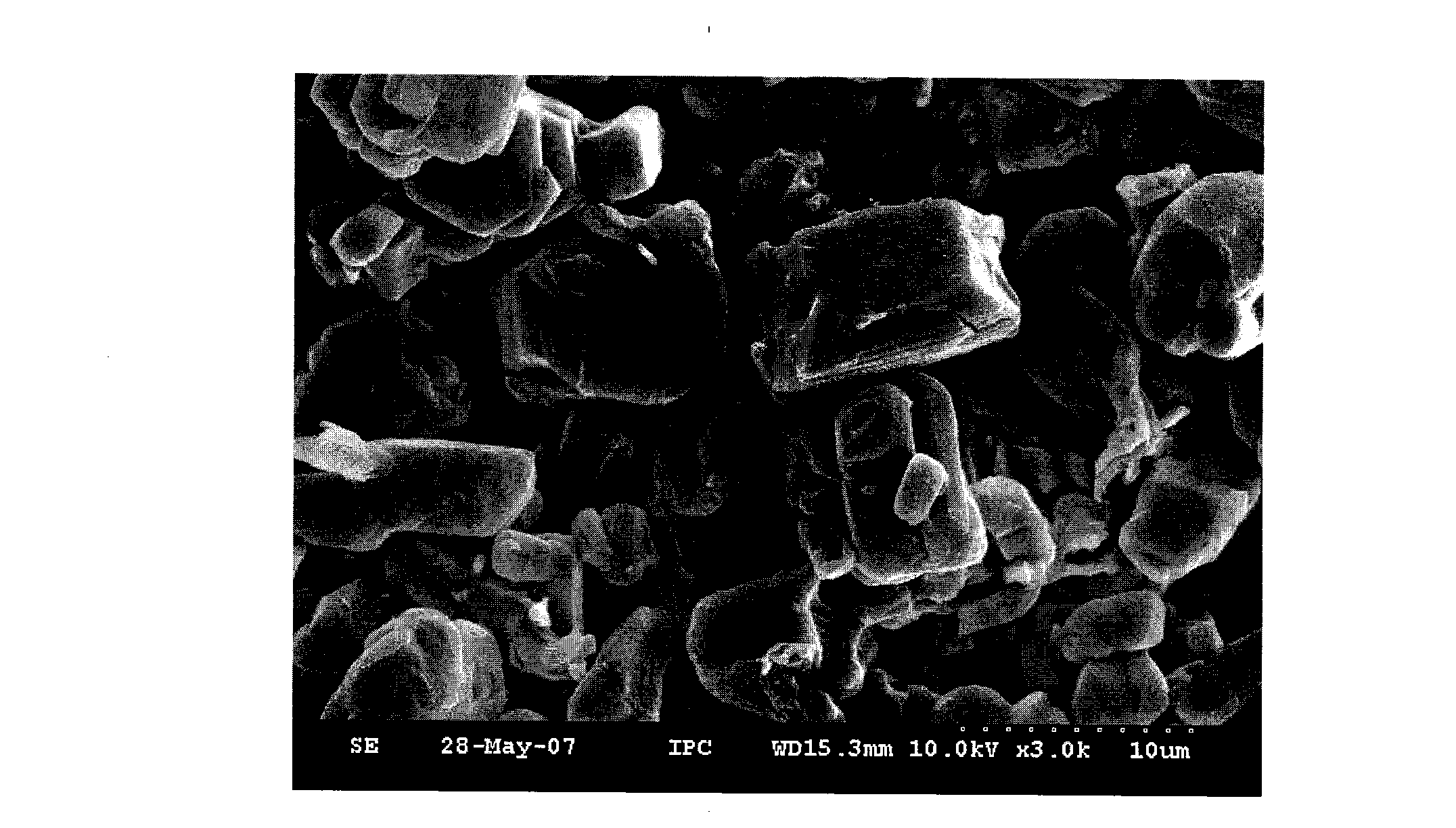

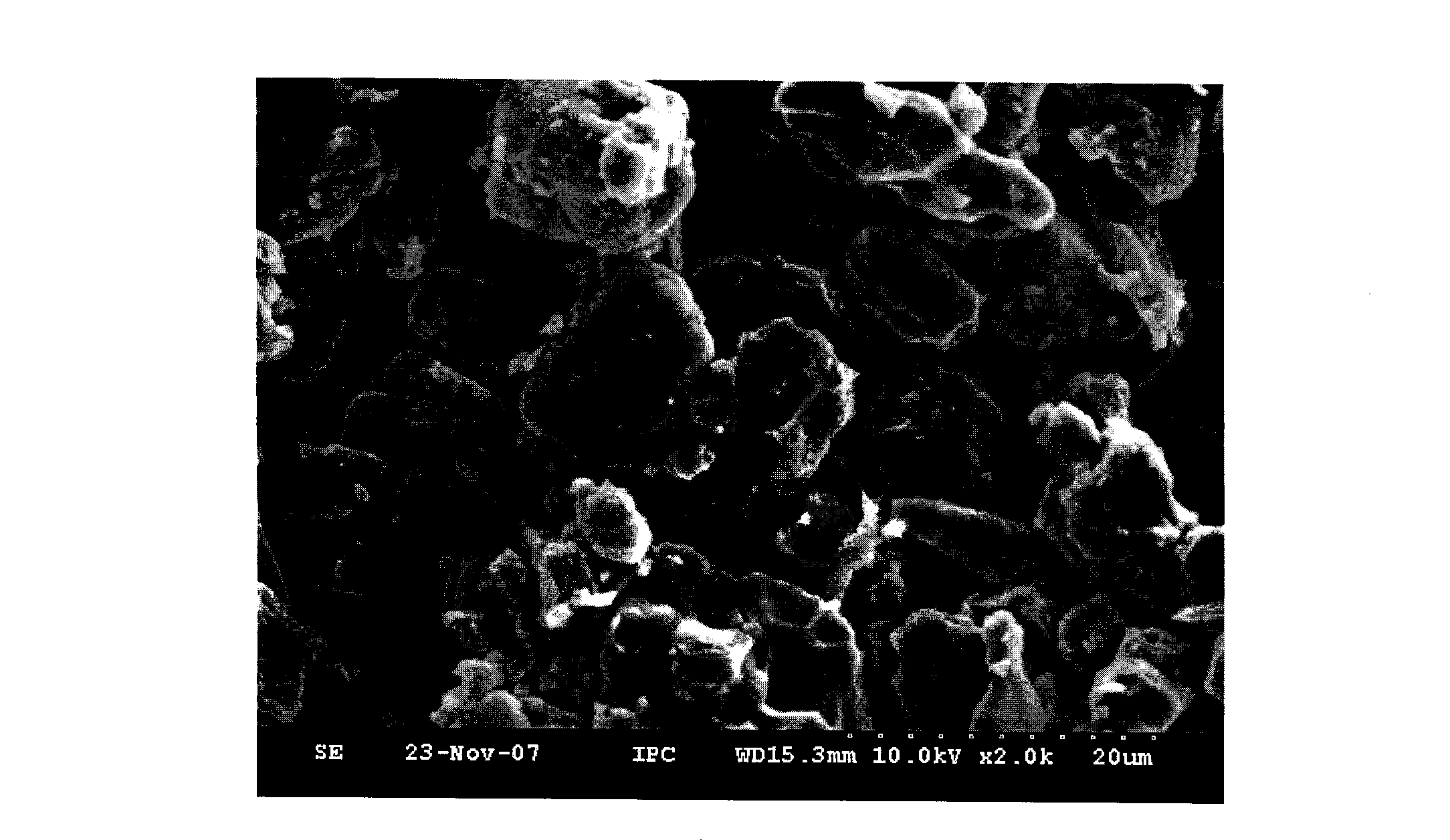

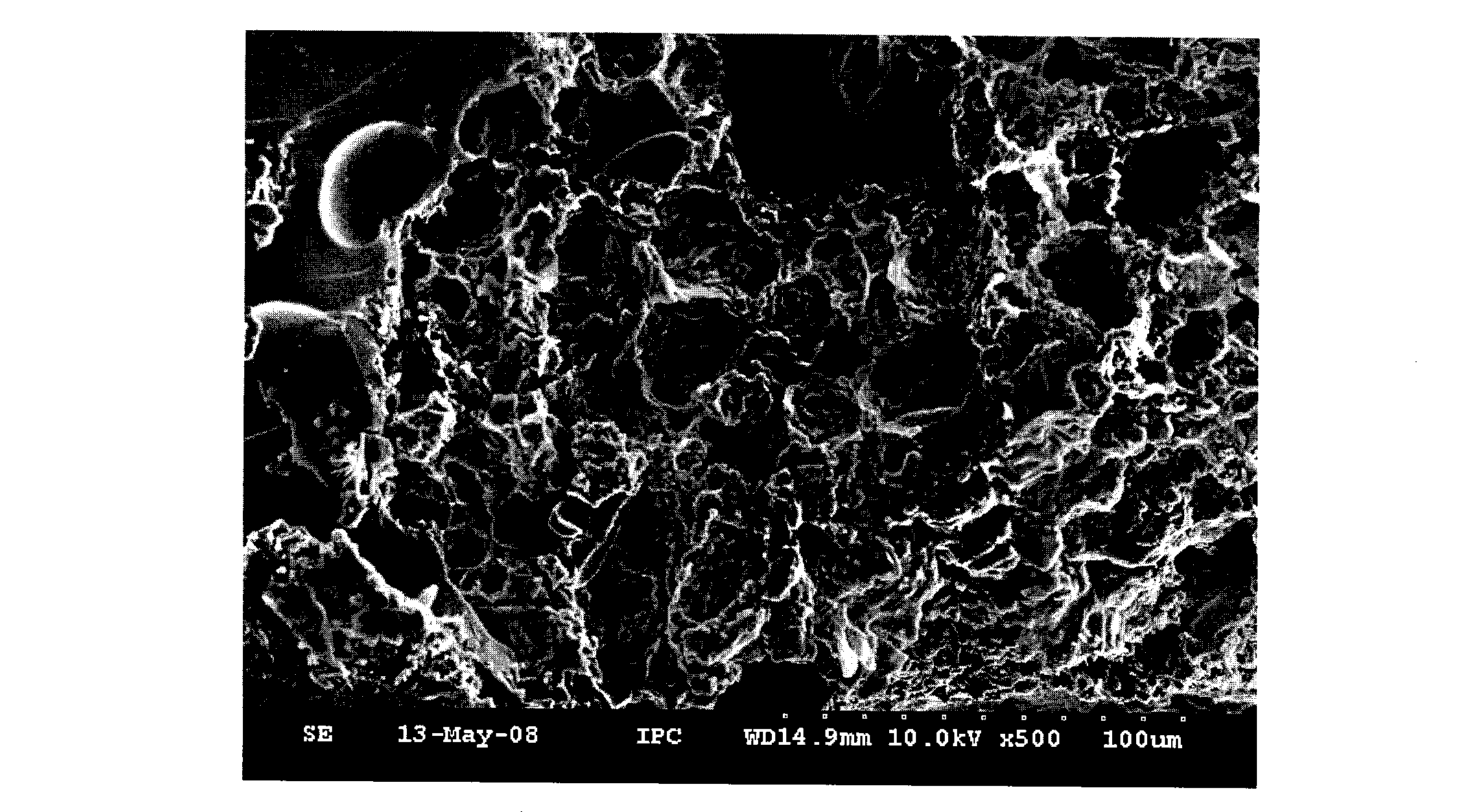

[0033] 100 grams of Type II APP (product of Sichuan Shifang Changfeng Chemical Co., Ltd., CF-APP201), 30 grams of MEL, 2.5 grams of 4A zeolite, the average particle size of the three components is about 2.0-15.0 microns, add to 250 grams of 95% In ethanol, stir evenly, add 0.75 g of γ-glycidoxypropyltrimethoxysilane (KH-560), and then add 0.10 g of ammonia. Under uniform stirring, heat from room temperature to 79°C, reflux for 1.5 hours, and cool to 70 ℃, add 1.2 grams of γ-aminopropyltriethoxysilane (KH-550) dropwise, heat to 79℃, reflux for 1.5 hours, cool to 70℃, add 2.0 grams of γ-glycidoxypropyltrimethoxysilane (KH-560), add 0.10 g of ammonia, reflux at 80°C for 2.5 hours, cool down, remove the solvent, and dry at 110°C for 0.5 hours to obtain a coated modified composite flame retardant (see figure 2 ), the surface of the uncoated ammonium polyphosphate is regular and smooth, with distinct edges and corners, and a regular square shape. The coated flame retardant has blurr...

Embodiment 2

[0038] 105 grams of melamine modified type II APP (product of Changfeng Chemical Co., Ltd., Sichuan Shifang City, CF-APP202), 35 grams of MEL, 3.5 grams of 4A zeolite, the average particle size of the three components is about 2.0-15.0 microns, add To 250 grams of 95% ethanol, stir evenly, add 0.80 grams of γ-glycidoxypropyltrimethoxysilane (KH-560), and then add 0.10 grams of ammonia, heat from room temperature to 79 ℃ under uniform stirring, reflux 1.5 After hours, the temperature is lowered to 70°C, 1.0 g of γ-aminopropyltriethoxysilane (KH-550) is added dropwise, heated to 79°C, refluxed for 1.5 hours, and the temperature is lowered to 70°C, 1.5 g of KH-550 is added, and heated to Reflow at 80°C for 2.5 hours, cool down, remove the solvent, and dry at 110°C for 0.5 hours to obtain a coated modified composite flame retardant.

[0039] Weigh 100 grams of the coated and modified composite flame retardant, add 80 grams of water, 1.0 grams of non-ionic surfactants (add 0), 125 gra...

Embodiment 3

[0042] 150 grams of epoxy resin coated Type II APP (product of Sichuan Shifang Changfeng Chemical Co., Ltd., CF-APP204), 30 grams of MEL, 5.0 grams of 4A zeolite, the average particle size of the three components is about 2.0-15.0 microns, add To 300 grams of 95% ethanol, stir evenly, add 1.5 grams of γ-glycidoxypropyltrimethoxysilane (KH-560), and then add 0.10 grams of ammonia, heat from room temperature to 79°C under uniform stirring, and reflux for 1.5 After hours, the temperature is lowered to 70°C, 1.5g of γ-aminopropyltriethoxysilane (KH-550) is added dropwise, heated to 79°C, refluxed for 1.5 hours, cooled to 70°C, 1.5g of γ-methacryloyl Oxypropyltrimethoxysilane (KH-570), heated to 80°C, then refluxed for 2.5 hours, cooled down, removed the solvent, and dried at 110°C for 0.5 hours to obtain a coated modified composite flame retardant.

[0043] Weigh 150 grams of the coated and modified composite flame retardant, add 100 grams of water, 1.0 grams of non-ionic surfactant ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com