Method for preparing mullite crystal whisker by non-hydrolytic sol-gel process

A technology of mullite whiskers and mullite, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve problems such as complex process, small size of mullite whiskers, complex process, etc., to achieve The process is simple, the inclusion of particles is less, and the effect of low preparation temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

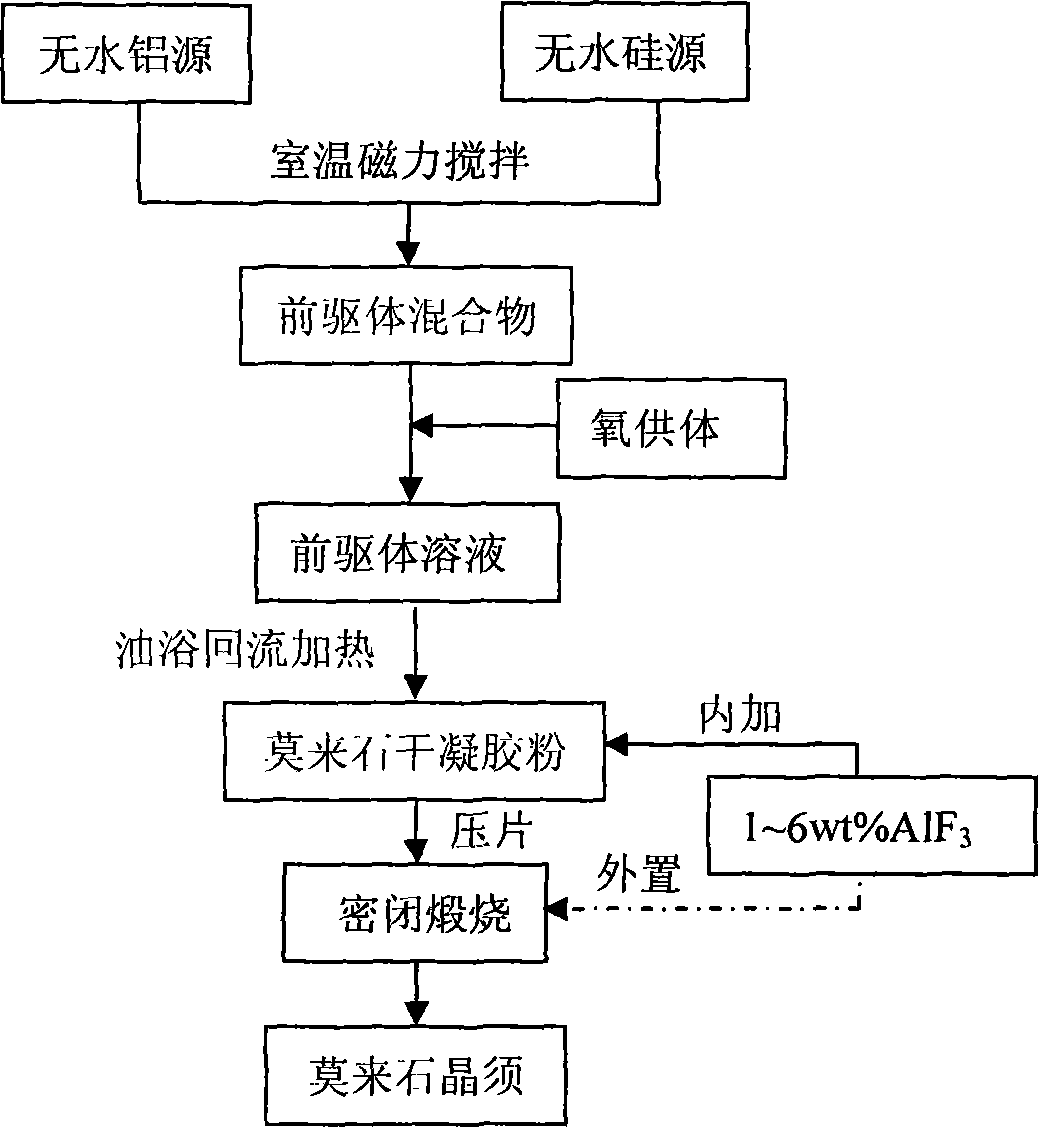

Method used

Image

Examples

Embodiment 1

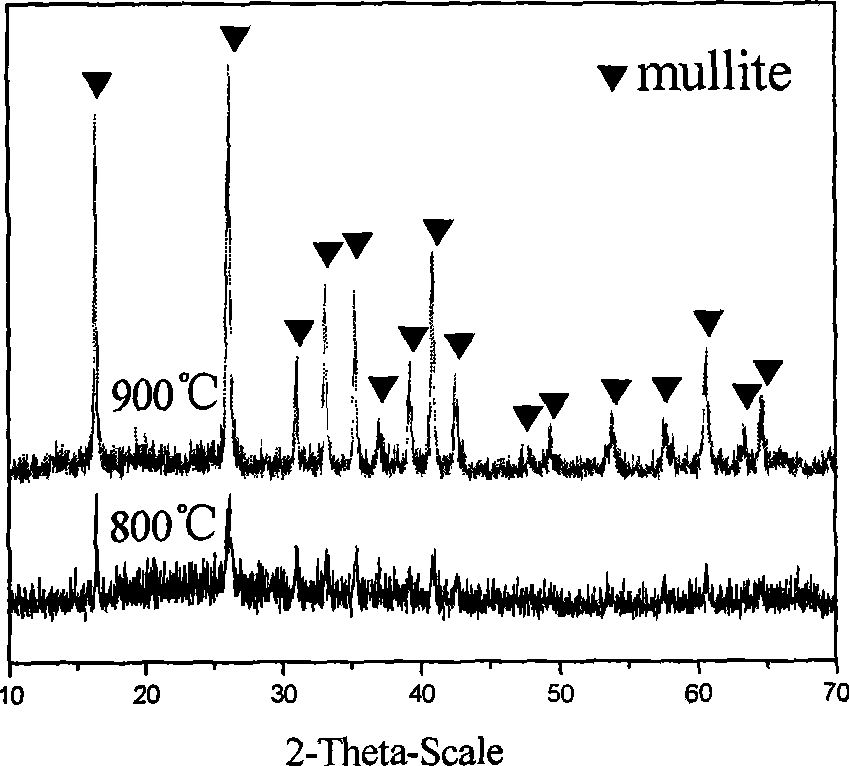

[0022] Si(OC 2 h 5 ) 4 (chemically pure), anhydrous AlCl 3 (analytical pure) as the precursor, anhydrous ether (chemically pure) as the oxygen donor, AlF 3 (Industrial pure) is a whisker catalyst. First, measure 0.0179mol Si(OC 2 h 5 ) 4 Place in a 100ml dry Erlenmeyer flask, add 0.0537mol anhydrous AlCl 3, stirred magnetically at room temperature to obtain a khaki precursor mixture, added 0.0448mol ether, and stirred for 15 minutes to obtain a black solution. The solution was placed in an oil bath at 110°C for reflux heating for 24 hours to obtain mullite xerogel; Grind and pass through a 250 mesh sieve to obtain xerogel powder. After granulating the xerogel powder, press it into a sheet-like sample in a powder tablet press under a pressure of 12 MPa, then place the sample in an alumina crucible for airtight calcination, and External 1wt% whisker catalyst AlF in the crucible 3 . The firing system is as follows: the heating rate is 4°C / min before 350°C, and then rais...

Embodiment 2

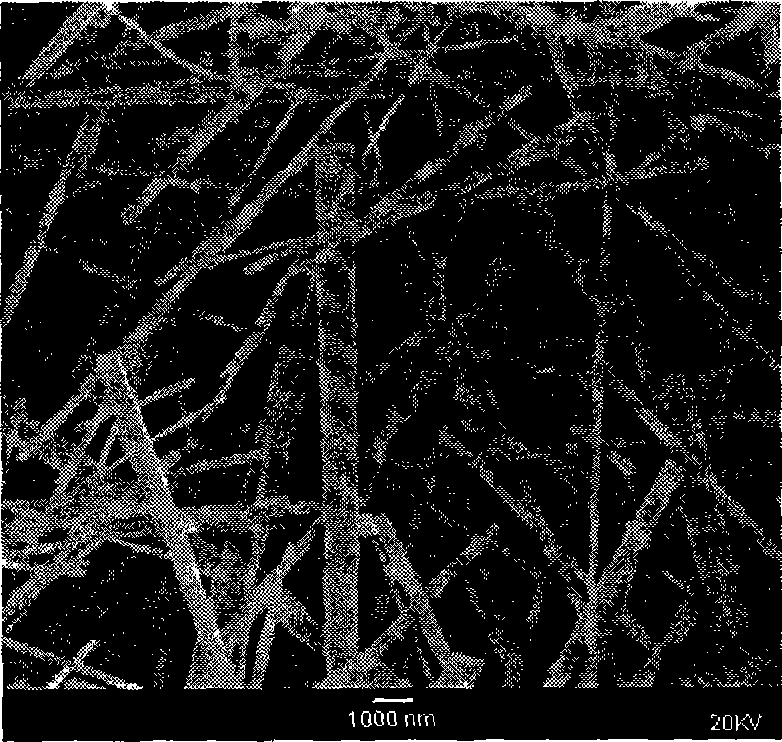

[0024] Si(OC 2 h 5 ) 4 (chemically pure), anhydrous AlCl 3 (analytical pure) as the precursor, anhydrous ether (chemically pure) as the oxygen donor, AlF 3 (Industrial pure) is a whisker catalyst. The amount of raw materials used to prepare mullite whiskers, the process flow and the firing system are the same as in Example 1, except that AlF 3 The dosage is 3wt%, and the morphology of the prepared mullite whiskers is shown in the appendix image 3 .

Embodiment 3

[0026] Si(OC 2 h 5 ) 4 (chemically pure), anhydrous AlCl 3 (analytical pure) as the precursor, anhydrous ether (chemically pure) as the oxygen donor, AlF 3 (Industrial pure) is a whisker catalyst. The amount of raw materials used to prepare mullite whiskers, the process flow and the firing system are the same as in Example 1, except that AlF 3 The consumption of is 6wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com