Luminophore and core-shell luminophore precursors

A technology for luminescent materials and precursors, applied in the field of preparing this new type of luminescent materials, can solve the problem of high cost and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0188] In the following examples, the prepared particles were characterized by particle size, morphology and composition by the following methods.

[0189] particle size measurement

[0190] Using a laser particle size analyzer (Malvern 2000), particle diameters were measured on particle samples dispersed in water and subjected to ultrasound (130W) for 1 minute and 30 seconds.

[0191] electron microscopy

[0192] Transmission electron micrographs were obtained on particle sections (microsection method) using a high-resolution JEOL 2010 FEG-type TEM microscope. The spatial resolution of the device for measuring chemical composition by EDS (Energy Dispersive Spectroscopy) is less than 2 nm. Correlation of the observed morphology with the measured chemical composition demonstrates the core-shell structure and allows measurement of shell thickness on micrographs.

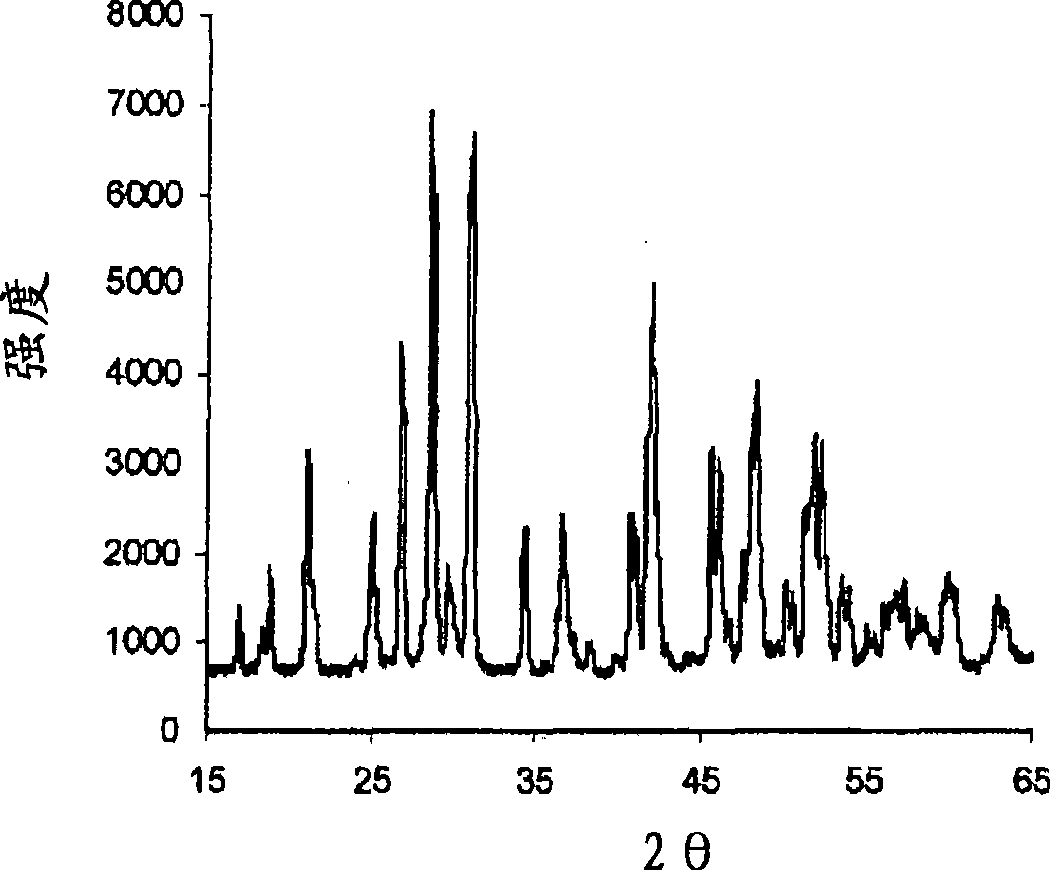

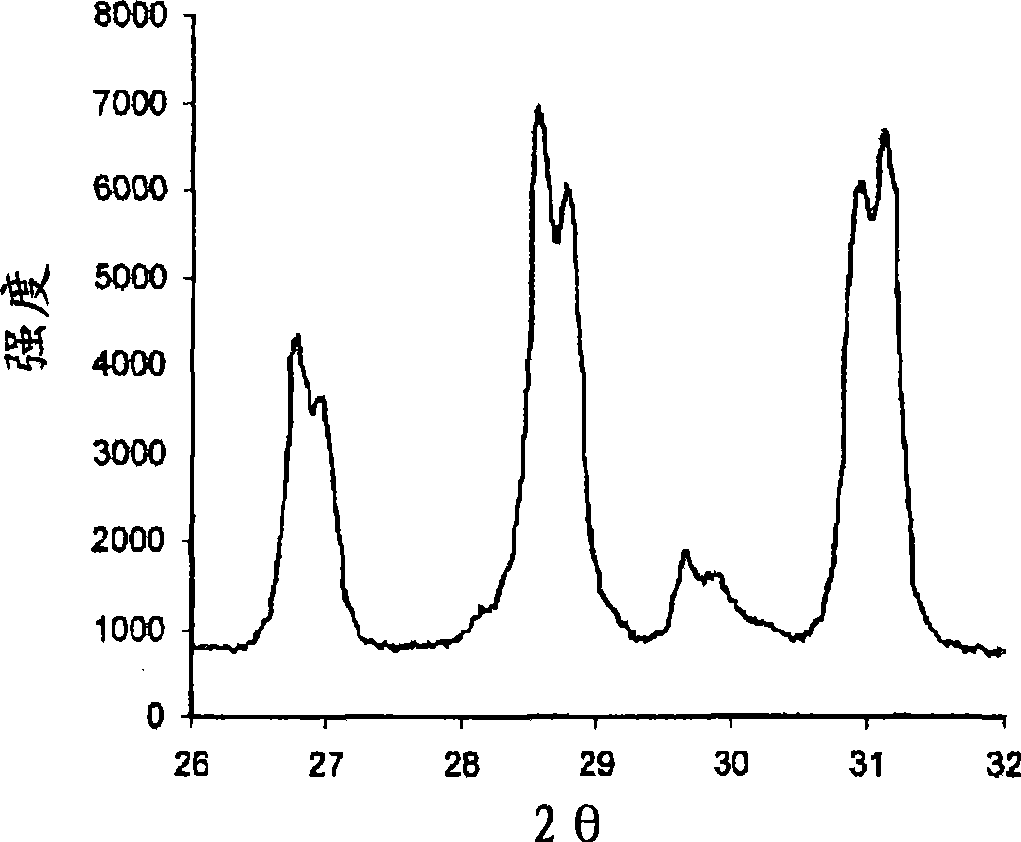

[0193] Determination of chemical composition by EDS was achieved by X-ray diffraction analysis of photographs...

Embodiment 1

[0200] Example 1 : LaPO 4 Synthesis of nuclear precursors

[0201] To 500ml of phosphoric acid H which had been brought to pH 1.6 by adding ammonia water and heated to 60°C over one hour 3 PO 4 Add 500ml of lanthanum nitrate solution (1.5mol / l) to the solution (1.725mol / l). During the precipitation the pH was adjusted to 1.6 by adding ammonia.

[0202] At the end of the precipitation step, the reaction medium is maintained at 60° C. for a further 1 h. The precipitate was then easily collected by filtration, washed with water, and then dried in air at 60°C. The obtained powder was then subjected to heat treatment at 900° C. in air.

[0203] Characterized by X-ray diffraction, the product thus obtained is lanthanum orthophosphate LaPO with monazite structure 4 . Particle size D 50 It is 5.2 μm and has a dispersion index of 0.6. The specific surface area S of the product measured by BET BET =6m 2 / g.

Embodiment 2

[0204] Example 2 : LaPO 4 Synthesis of nuclear precursors

[0205] After one hour, add ammonia water to make the pH value reach 1.9 and heat to 500ml phosphoric acid H at 60°C. 3 PO 4 Add 500ml of lanthanum nitrate solution (1.5mol / l) to the solution (1.725mol / l). During the precipitation the pH was adjusted to 1.9 by adding ammonia.

[0206] At the end of the precipitation step, the reaction medium is maintained at 60° C. for a further 1 h. The precipitate was then easily collected by filtration, washed with water, and then dried in air at 60°C. The obtained powder was then subjected to heat treatment at 900° C. in air.

[0207] Characterized by X-ray diffraction, the product thus obtained is lanthanum orthophosphate LaPO with monazite structure 4 . Particle size D 50 It is 4.3 μm and has a dispersion index of 0.4.

[0208] The powder was then calcined in air at 1100 °C for 2 h. Thus the particle size D 50 Rare earth phosphate with a diameter of 4.9 μm, a dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com