Magnetic spinel structure ferrite nano particle and preparation thereof

A spinel structure and nanoparticle technology, applied in chemical instruments and methods, iron compounds, cobalt compounds, etc., can solve problems such as complex operations, high production costs, and environmental pollution, and achieve low yield and strong applicability , the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Weigh 2.67g of cobalt chloride, and dissolve 6.23g of ferrous sulfate in 60ml of deionized water to obtain a 0.56M metal ion solution;

[0025] 2) Weigh 3.60 g of sodium hydroxide and dissolve it in 30 ml of deionized water to obtain a 3M alkali metal hydroxide solution;

[0026] 3) The two solutions prepared in steps 1) and 2) were stirred and forcedly mixed at room temperature to obtain a slurry;

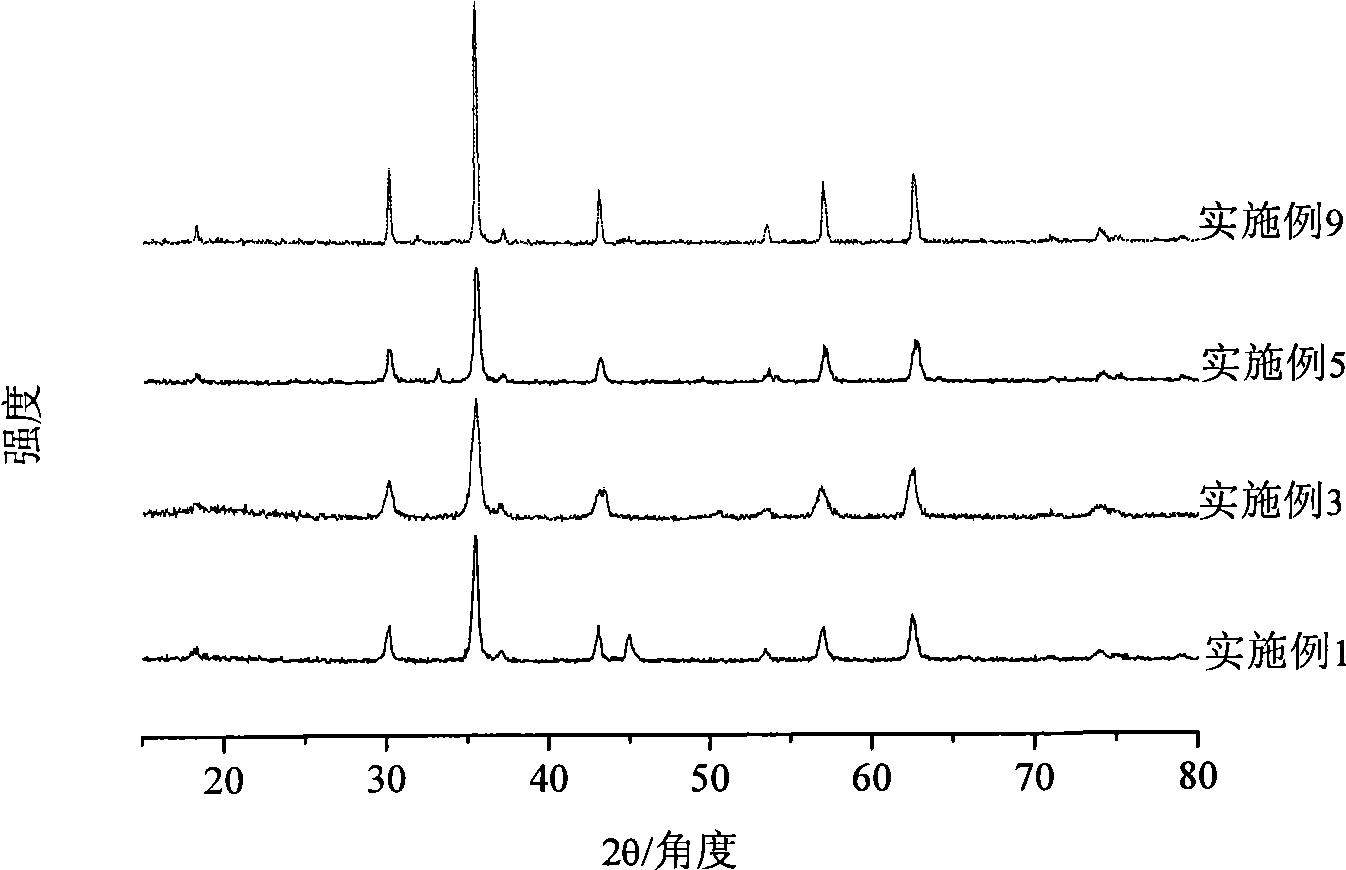

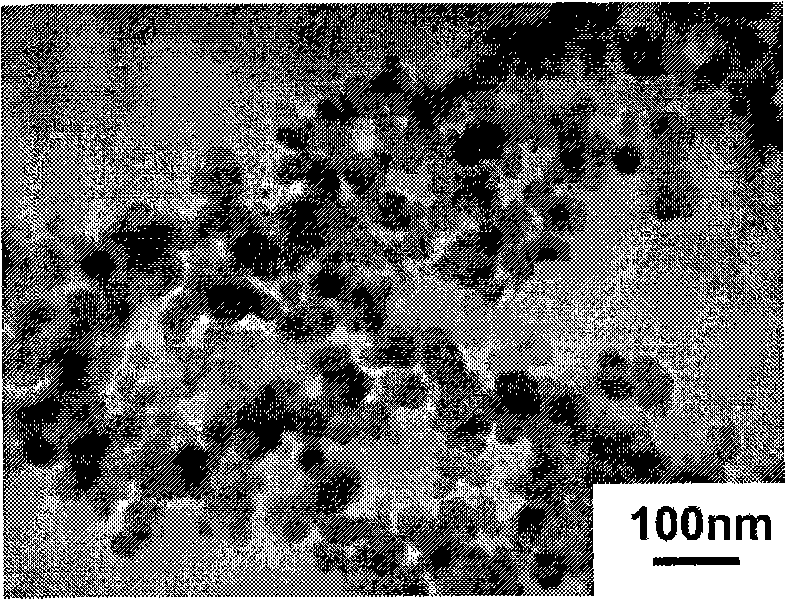

[0027] 4) The slurry obtained in step 3) was continuously stirred for 5 minutes, then placed in an 80ml polytetrafluorohydrothermal tank, and heated at 160°C for 4 hours, and the obtained precipitate was centrifuged, washed and dried to obtain a black powder, the product for CoFe 2 o 4 ,Such as figure 2 As shown, the product is spherical, about 30nm, Figure 8 The middle line 1 is the hysteresis loop of the product, and the saturation magnetization is 95.23emu / g.

Embodiment 2

[0029] 1) Weigh 0.05g of copper chloride, 0.04g of zinc chloride, 2.53g of cobalt chloride, and 6.23g of ferrous sulfate and dissolve them in 60ml of deionized water to obtain a 0.56M metal ion solution;

[0030] 2) Weigh 3.60 g of sodium hydroxide and dissolve it in 30 ml of deionized water to obtain a 3M alkali metal hydroxide solution;

[0031] 3) The two solutions prepared in steps 1) and 2) were stirred and forcedly mixed at room temperature to obtain a slurry;

[0032] 4) The slurry obtained in step 3) was continuously stirred for 5 minutes, then placed in an 80ml polytetrafluorohydrothermal tank, and heated at 160°C for 4 hours, and the obtained precipitate was centrifuged, washed and dried to obtain a black powder, the product for Co 0.95 Cu 0.025 Zn 0.025 Fe 2 o 4 , spherical, about 30nm, saturation magnetization 92.75emu / g.

Embodiment 3

[0034] 1) Weigh 0.76g of copper chloride, 0.61g of zinc chloride, 0.53g of cobalt chloride, and 6.23g of ferrous sulfate and dissolve them in 60ml of deionized water to obtain a 0.56M metal ion solution;

[0035] 2) Weigh 3.6 g of sodium hydroxide and dissolve it in 30 ml of deionized water to obtain a 3M alkali metal hydroxide solution;

[0036] 3) The two solutions prepared in steps 1) and 2) were stirred and forcedly mixed at room temperature to obtain a slurry;

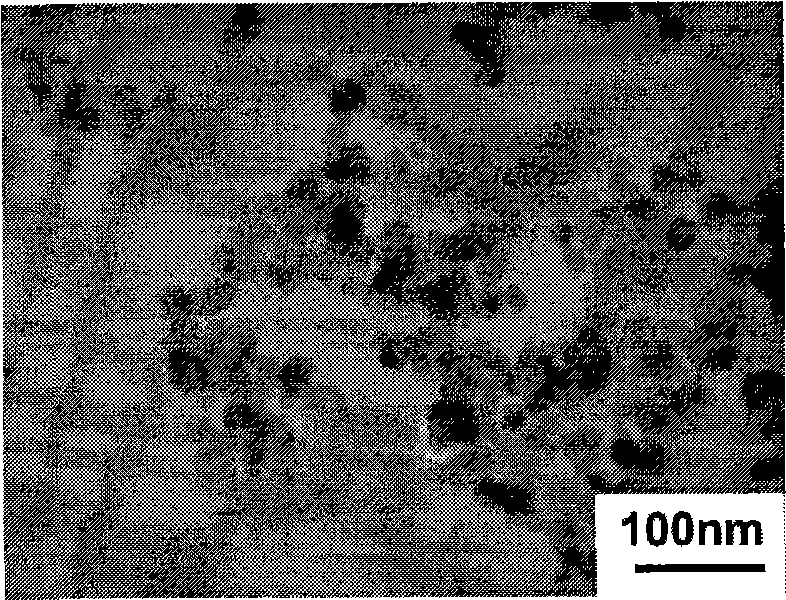

[0037] 4) The slurry obtained in step 3) was continuously stirred for 5 minutes, then placed in an 80ml polytetrafluorohydrothermal tank, and heated at 160°C for 4 hours, and the obtained precipitate was centrifuged, washed and dried to obtain a black powder, the product for Co 0.2 Cu 0.4 Zn 0.4 Fe 2 o 4 ,Such as image 3 As shown, the product is spherical, about 20nm, Figure 8 The middle line 3 is the hysteresis loop of the product, and the saturation magnetization is 70.38emu / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com