Oil press for automatically moulding rare-earth magnetic powder

A technology of automatic forming and rare earth magnetic powder, which is applied in the field of automatic forming hydraulic press of rare earth magnetic powder to achieve the effect of improving production efficiency, reducing failure rate and maintenance time, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

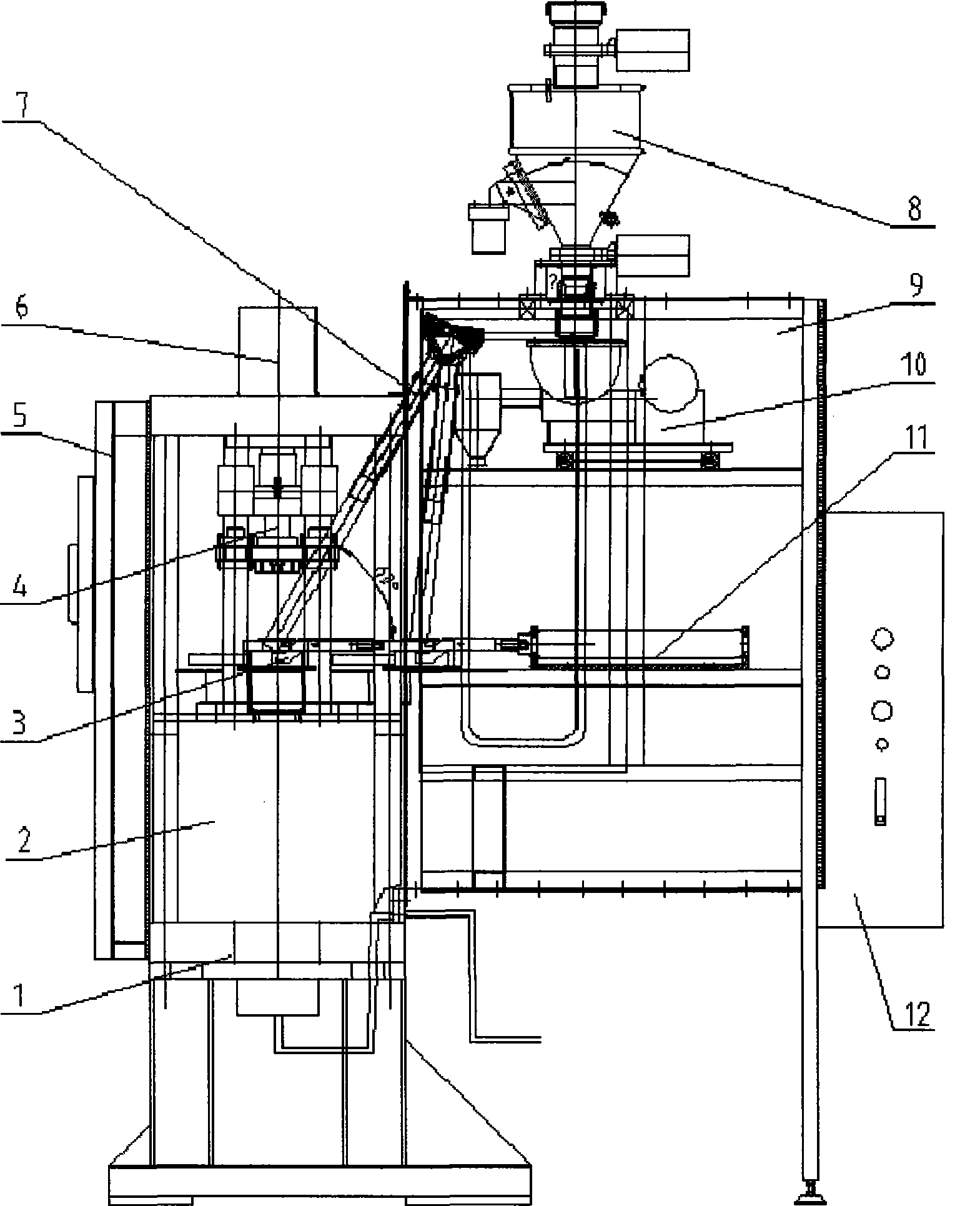

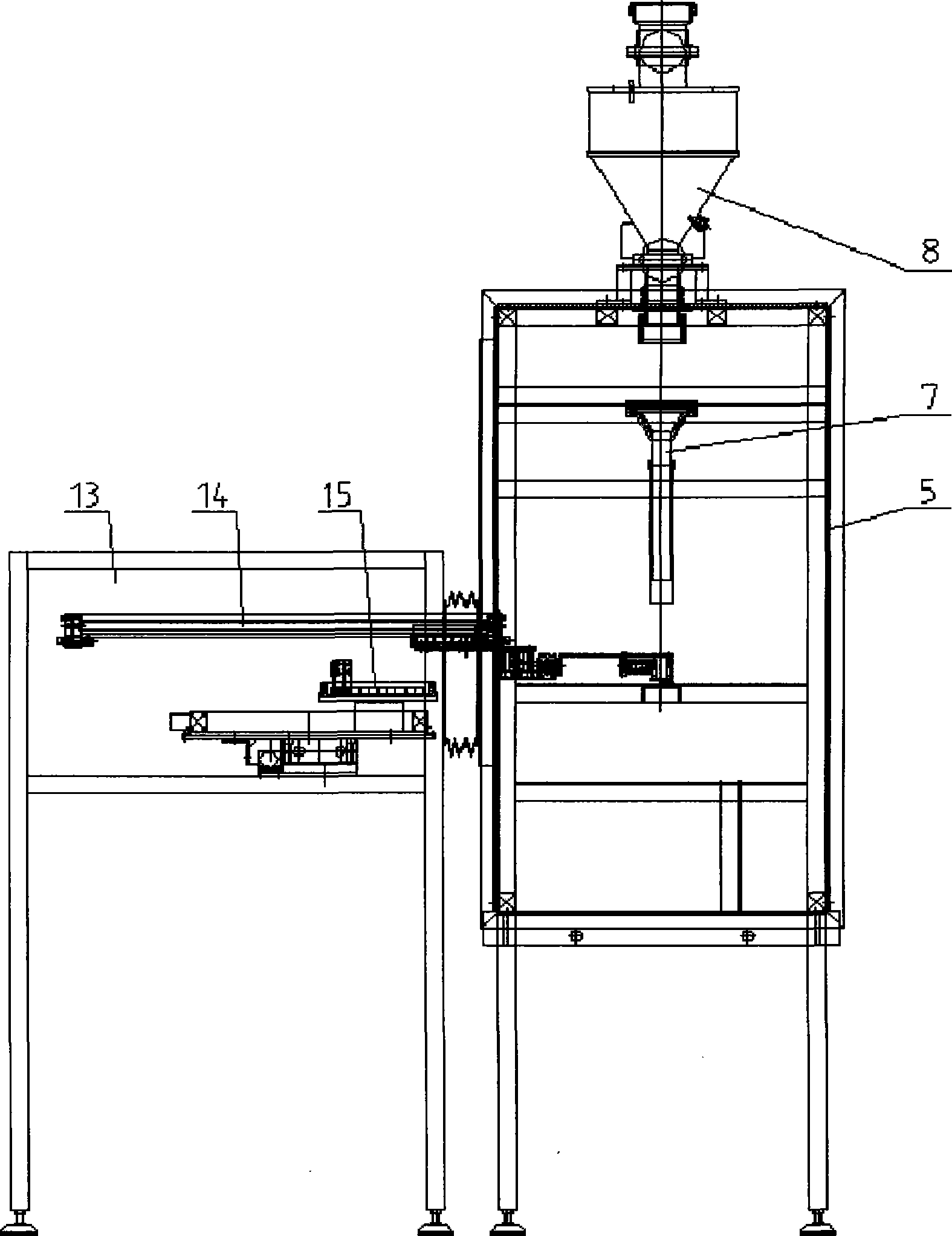

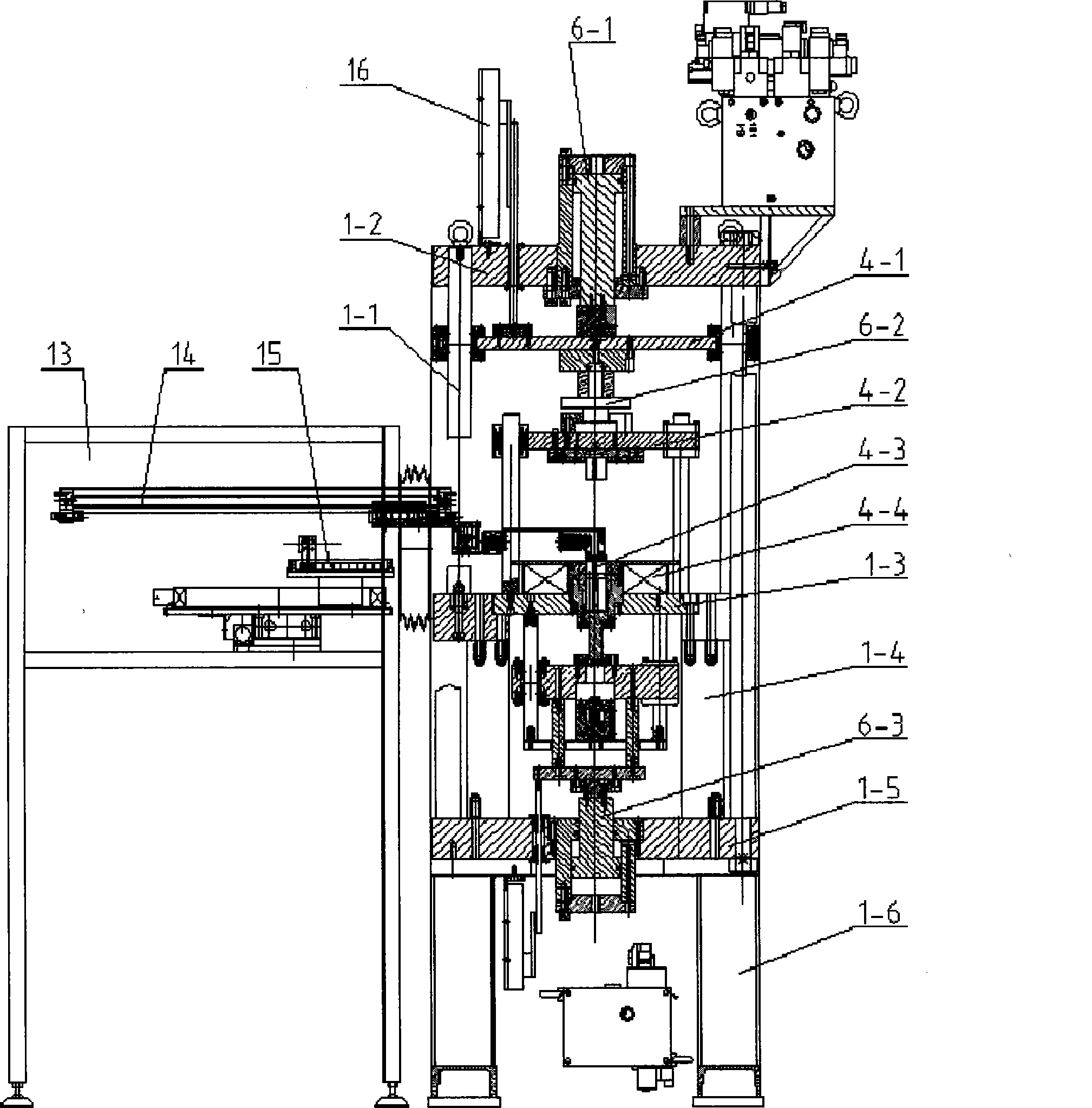

[0022] see Figure 1-4 , Rare earth magnetic powder automatic forming hydraulic press, composed of feeding system (9), forming pressing system (2), retrieving system (13) and electrical control system (12), feeding and feeding system (9), forming pressing system The system (2) and the reclaiming system (13) are connected to each other in the shape of a character. The shell (5) is sealed with transparent material organic glass, and the interior is connected to each other. An oxygen content detector is installed and filled with an inert protective gas (such as argon gas) etc.), the completely closed system controls the inert gas environment so that the rare earth magnetic powder will not be oxidized.

[0023] Feeding system (9) includes casing (5), feeding shoe (3), telescopic tube (7), hopper (8), weighing device (10), feeder drive cylinder (11) and hydraulic and electrical The control assembly is equipped with a hopper (8) at the top of the feeding system (9), the hopper (8) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com