Automatic radioactive material packaging method and system

A packaging method and radioactive technology, applied in radioactive purification, portable protective containers, nuclear engineering, etc., can solve problems affecting the health of workers, radioactive leakage, lax packaging, etc., to reduce labor costs, ensure full automation, and improve The effect of packaging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] First, in order to better illustrate the automatic packaging method for radioactive materials of the present invention, the automatic packaging system for implementing the automatic packaging method will be described in detail.

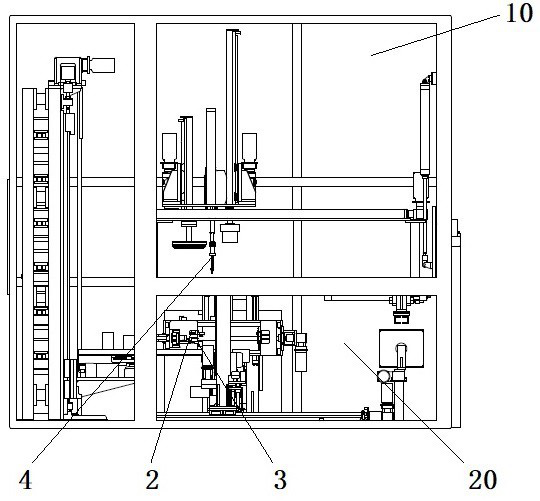

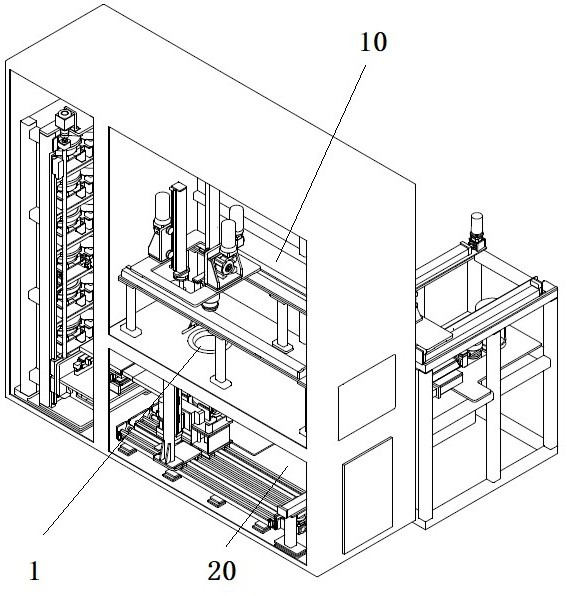

[0059] Such as figure 1 , 2 As shown, the automatic packaging method is carried out in the automatic packaging system. The automatic packaging system first includes a closed system, which is divided into upper and lower two-layer spaces; considering that the packaged materials contain radioactive substances, the described The upper and lower floors are isolated from each other at all times to further ensure that radioactive materials will not leak into any undesired spaces. Among them, the upper space 10 of the closed system is provided with a number of mobile components to transfer the radioactive materials that are about to be packaged by other suitable transport mechanisms or to execute any required transfer instructions; the lower space 20...

Embodiment 2

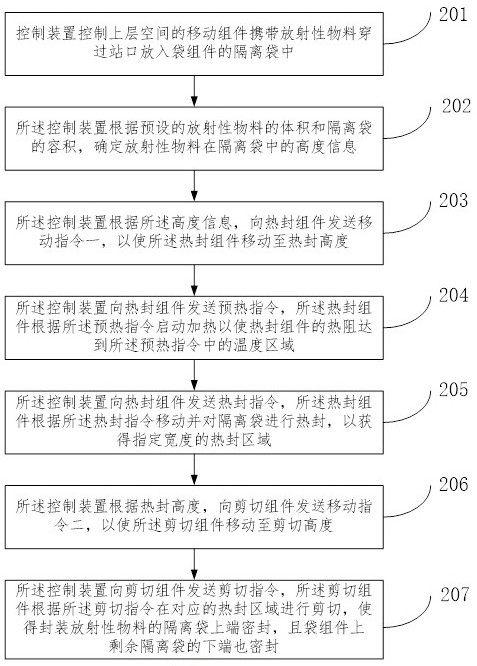

[0072] Based on the aforementioned figure 1 , 2 As shown in the packaging system, the embodiment of the present invention also provides an automatic packaging method for radioactive materials. The execution body of the method can be a control device. Always isolate during bagging. The packaging method of this embodiment may include the following steps, such as image 3 shown.

[0073] 201. The control device controls the mobile assembly in the upper space to carry radioactive materials through the station opening and put them into the plastic bag of the plastic bag assembly; the plastic bag of the plastic bag assembly is nested on the outer edge of the station entrance in the lower space.

[0074] In practical applications, the material to be packaged is transported to a designated area of the upper space via a special transfer channel or a transfer device, which is not limited in this embodiment and can be adjusted according to actual needs. Since the transfer channel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com