Inductive heating and open-close type heating fixture based on sensor

A technology of induction heating and fixing device, applied in electric heating device, metal processing, metal processing equipment, etc., can solve the problems of inability to take out the sensor, high labor experience, pollution of the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

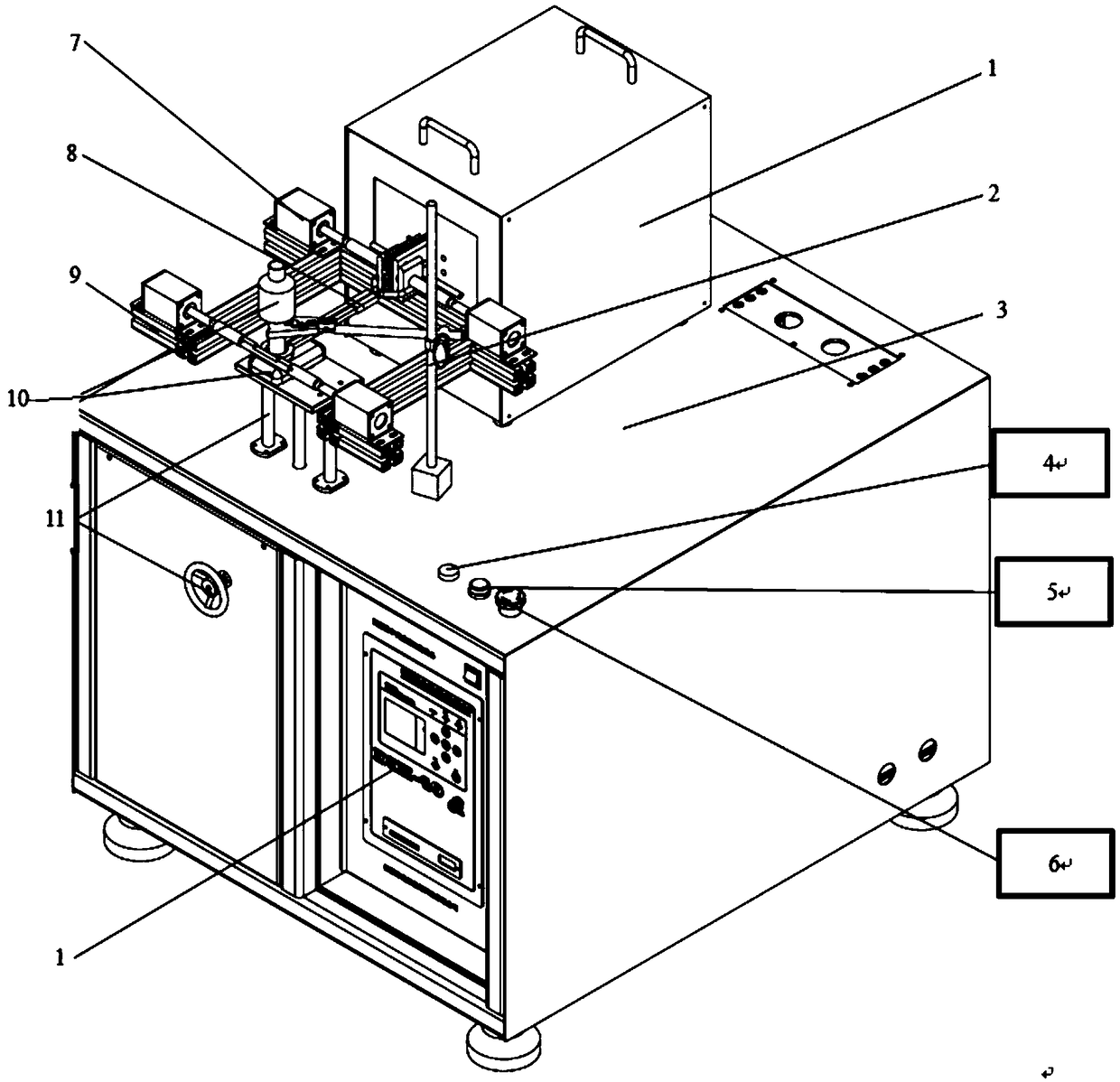

[0022] The present invention is described in further detail below in conjunction with accompanying drawing:

[0023] like figure 1 As shown, an open-close heating and fixing device based on induction heating of an inductor includes a high-frequency brazing equipment 1 and an open-close induction wire device 8, and the open-close type induction wire device 8 is composed of a left half induction wire device and a right half induction wire device A complete induction wire device is formed, the left half induction wire device and the right half induction wire device are connected to the high-frequency brazing equipment 1, and the left half induction wire device and the right half induction wire device are respectively fixed to the movable fixed device; during use , the left half of the induction wire and the right half of the induction wire are moved by the movable fixed device to make the two fit together, and after forming a complete induction wire, they are connected with the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com