Terahertz GaN Gunn diode based on conducting type SiC substrate and manufacturing process thereof

A technology of Gunn diode and manufacturing method, which is applied in the field of microelectronics, can solve the problems of low output power, achieve the effects of improving heat dissipation, reducing parasitic series resistance, and reducing parasitic series resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The invention manufactures a terahertz GaN Gunn diode based on a 2-inch n-type conduction type 4H-SiC substrate.

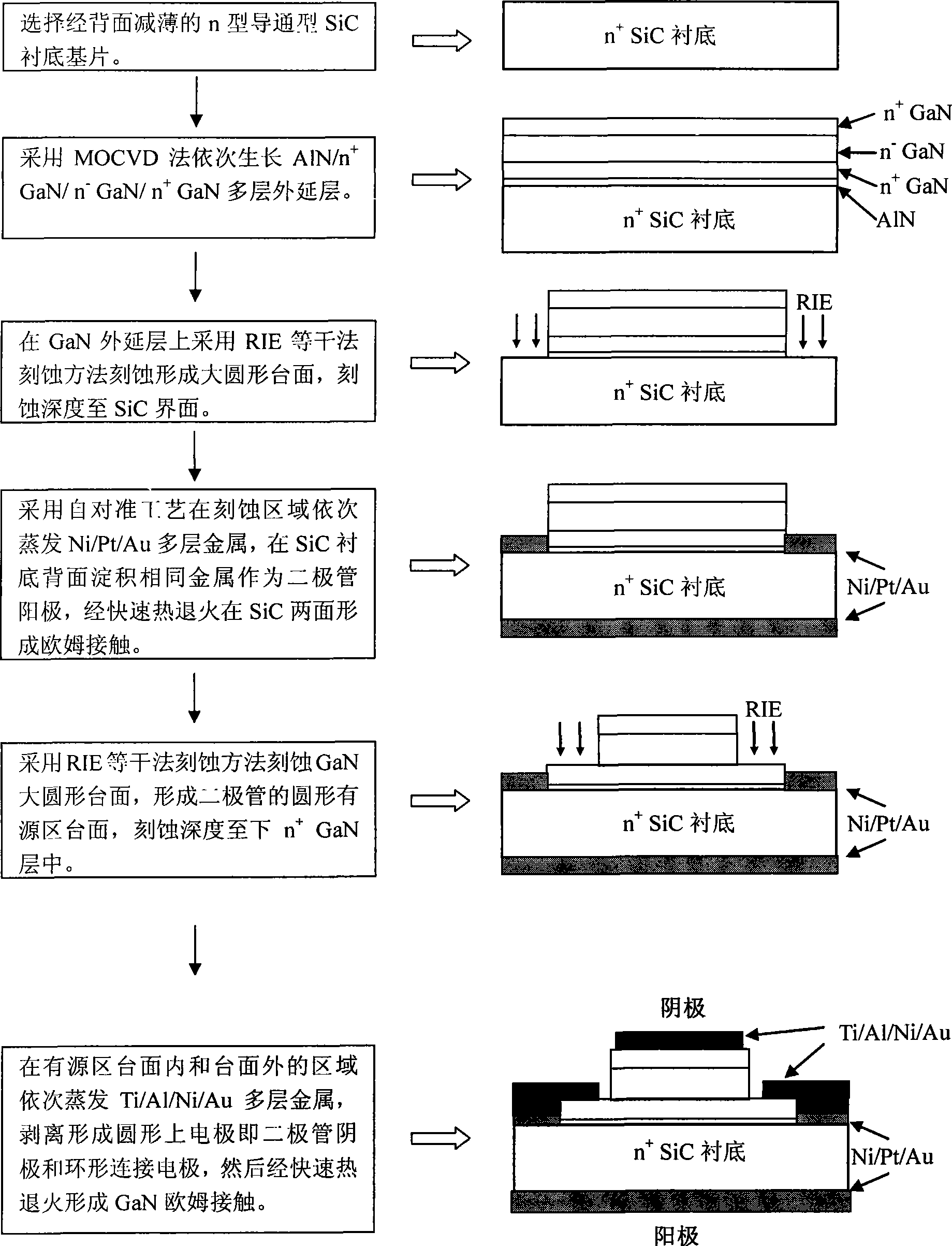

[0052] refer to image 3 Technological process, the production process of the present embodiment is as follows:

[0053] 1. Select a 2-inch 4H-SiC conduction-type n-type SiC substrate with a doping concentration of 5×10 18 cm -3 , the backside is thinned to a substrate thickness of 150 μm.

[0054] 2. Trimethylaluminum and high-purity ammonia are used as aluminum and nitrogen sources on MOCVD, and a low-temperature AlN nucleation layer is first grown on the SiC substrate at a temperature of about 600°C and a pressure of 40 Torr, with a thickness of 30nm.

[0055] 3. Using triethylgallium and high-purity ammonia gas as the source of gallium and nitrogen, and silane gas as the n-type doping source, control the temperature at 950°C and the pressure at 40 torr, and grow a layer of high-temperature n on the AlN nucleation layer. + GaN layer with a doping co...

Embodiment 2

[0068] The invention manufactures a GaN Gunn diode based on a 2-inch n-type conduction type 6H-SiC substrate and SiN passivation.

[0069] refer to image 3 Technological process, the production process of the present embodiment is as follows:

[0070] 1. Select a 2-inch 6H-SiC conduction-type n-type SiC substrate with a doping concentration of 5×10 18 cm -3 , the back side is thinned to a substrate thickness of 200 μm.

[0071] 2. Trimethylaluminum and high-purity ammonia are used as aluminum and nitrogen sources on MOCVD, and a low-temperature AlN nucleation layer is first grown on the SiC substrate at a temperature of about 600°C and a pressure of 40 torr, with a thickness of 50nm.

[0072] 3. Using triethylgallium and high-purity ammonia gas as the source of gallium and nitrogen, and silane gas as the source of n-type doping, control the temperature at 950°C and the pressure at 40 torr, and grow a layer of high-temperature n on the AlN nucleation layer. + GaN layer wi...

Embodiment 3

[0086] The invention manufactures a terahertz GaN Gunn diode based on a 3-inch n-type conduction type 4H-SiC substrate.

[0087] refer to image 3 Technological process, the production process of the present embodiment is as follows:

[0088] 1. Use a 3-inch 4H-SiC conduction-type n-type SiC substrate with a doping concentration of 5×10 18 cm -3 , the back side is thinned to a substrate thickness of 300 μm.

[0089] 2. Trimethylaluminum and high-purity ammonia are used as aluminum and nitrogen sources on MOCVD, and a low-temperature AlN nucleation layer is first grown on the SiC substrate at a temperature of about 600 °C and a pressure of 40 Torr, with a thickness of 40nm.

[0090] 3. Using triethylgallium and high-purity ammonia gas as the source of gallium and nitrogen, and silane gas as the n-type doping source, control the temperature at 950°C and the pressure at 40 torr, and grow a layer of high-temperature n on the AlN nucleation layer. + GaN layer with a doping con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com