CVD diamond layer overlapped diamond composite sheet for drilling and its production method

A technology of diamond composite sheet and diamond layer, which is applied in the field of diamond composite sheet for drilling and its production, can solve the problems of reduced impact resistance, PDC bit teeth that cannot achieve wear resistance and service life, and improve temperature resistance and durability. Effects of abrasiveness and service life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

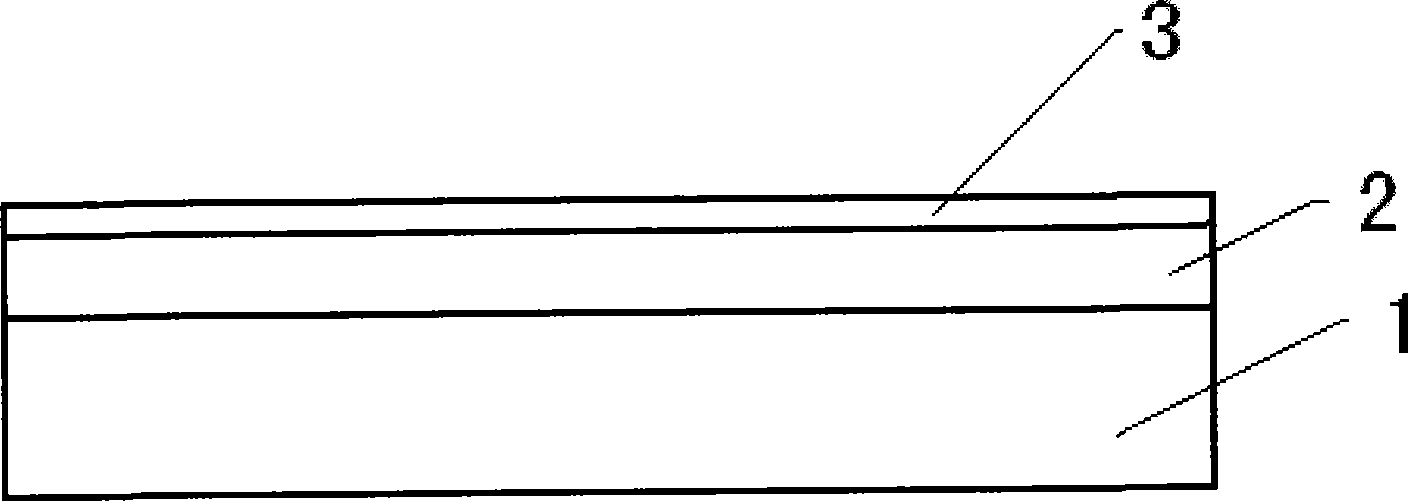

[0018] Embodiment 1: as figure 1 As shown, a diamond composite sheet for drilling covered with CVD diamond coating is deposited and covered with a 0.01-2mm thick CVD diamond film 3 on the PCD surface 2 of the PDC sheet 1 by chemical vapor deposition.

[0019] A method for manufacturing a diamond composite sheet for drilling covered with a CVD diamond layer, comprising the step of removing cobalt from the PCD layer before depositing the CVD diamond film;

[0020] Proceed as follows:

[0021] Immerse the diamond layer of PCD in 1:3 nitric acid aqueous solution (or other decobalt solution) for half an hour (or longer);

[0022] or with 2.5% CO-H 2 Plasma (other active plasma) selectively etches Co;

[0023] Or use Ar ion sputtering to etch the PCD surface to reduce the Co content;

[0024] A 0.01-2mm thick CVD diamond film is deposited on the PCD surface of the PDC sheet by chemical vapor deposition;

[0025] Proceed as follows:

[0026] Put the surface-treated PCD sheet on...

Embodiment 2

[0027] Embodiment 2: a kind of diamond composite sheet manufacturing method for drilling covering the CVD diamond layer does not carry out the cobalt-removing step to the PCD layer before depositing the CVD diamond film;

[0028] Proceed as follows:

[0029] Put the PCD sheet on the substrate table of the vacuum chamber, control the surface temperature of the PCD below 500°C, and use chemical vapor deposition methods such as microwave plasma, DC glow discharge plasma, plasma jet, hot wire method, etc., to deposit The carbon-containing gas source (or liquid source) is decomposed, and a 0.01-2mm thick CVD diamond film is deposited on the PCD surface.

Embodiment 3

[0030] Embodiment 3: A method for making a diamond composite sheet for drilling covered with a CVD diamond layer, deposited in an atmospheric environment;

[0031] Put the PCD sheet on the substrate table in the atmospheric atmosphere, use arc discharge, multi-laser beam and other chemical vapor deposition methods to decompose the carbon-containing gas source (or liquid source), and deposit a layer of 0.01-2mm thick on the PCD surface. CVD diamond film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com