High-dispersion manganese-cerium composite oxides and preparation method thereof

A composite oxide, manganese-cerium technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc. Effects of excellent reactivity and stability, stable properties, good redox and O2 affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Manganese-cerium composite oxide was prepared according to the following process

[0018] 1) According to the required ratio of manganese and cerium, configure a potassium permanganate, manganese acetate, cerium nitrate solution and a concentration of 0.2mol / L potassium hydroxide solution with a concentration of 0.1mol / L;

[0019] 2) Under the condition of vigorous stirring at 50°C, add the above solution dropwise, mix, and continue to stir for 1 hour after the dropwise addition is completed;

[0020] 3) The resulting precipitate was washed with hot water at 50°C, filtered with suction, and dried at 110°C for 8 hours. The obtained precursor was designated as S 1 . continue to S 1 The precursor was calcined at 500°C for 2 hours, and the obtained manganese-cerium composite oxide was denoted as S 2 .

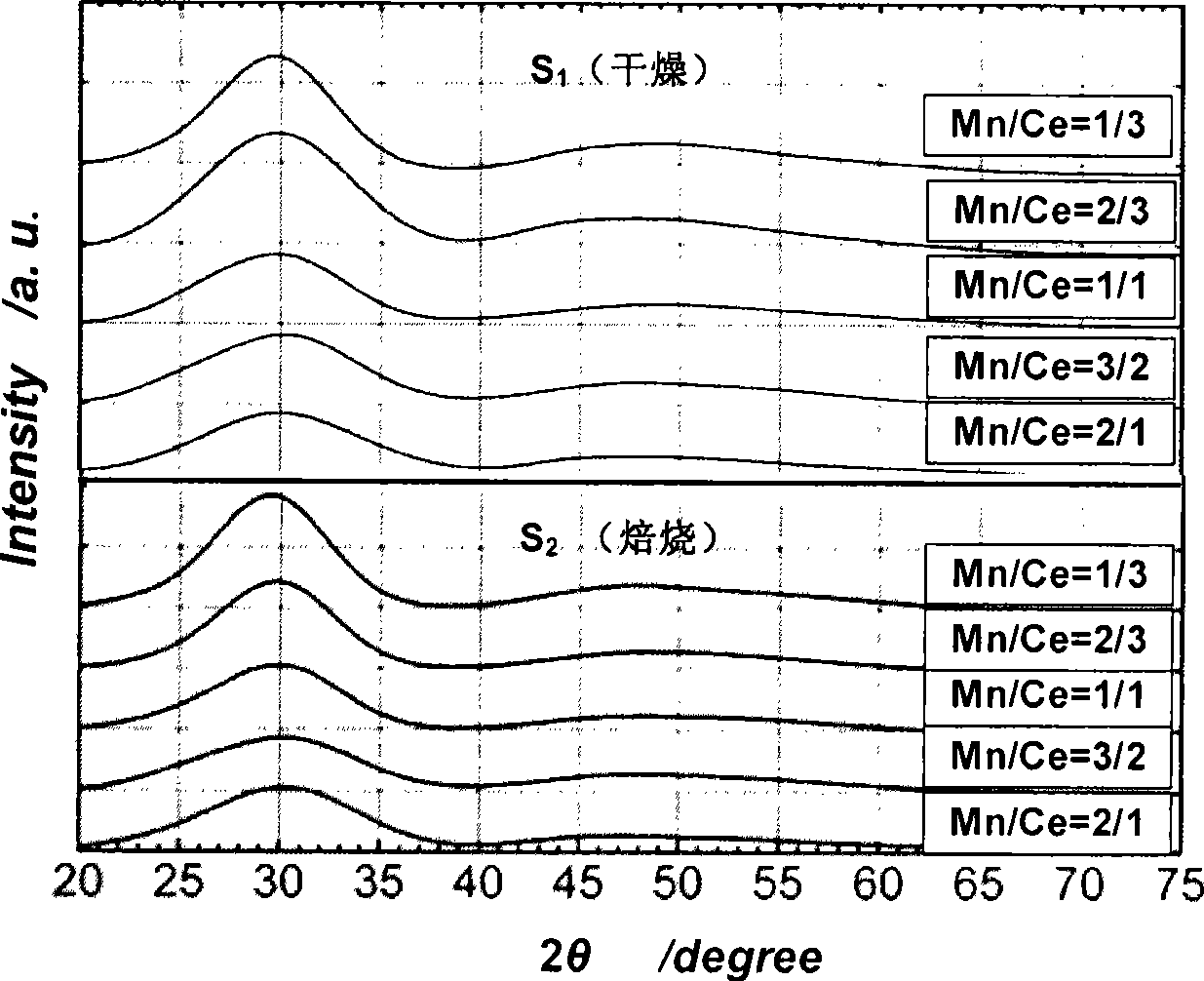

[0021] from S 1 and S 2 Take an appropriate amount of samples for BET analysis, Raman spectral analysis and XRD analysis ( figure 1 ). BET analysis results showed th...

Embodiment 2

[0023] According to the steps in Example 1, a manganese-cerium composite oxide with a manganese-cerium ratio of 1:1 was prepared. Based on 0.25wt% Pt content, the manganese-cerium composite oxide was impregnated with dinitrosodiammine platinum solution, dried at 110°C, and activated for 2 hours after roasting at 450°C to obtain Pt-loaded manganese-cerium composite oxide Pt / MnCeOx .

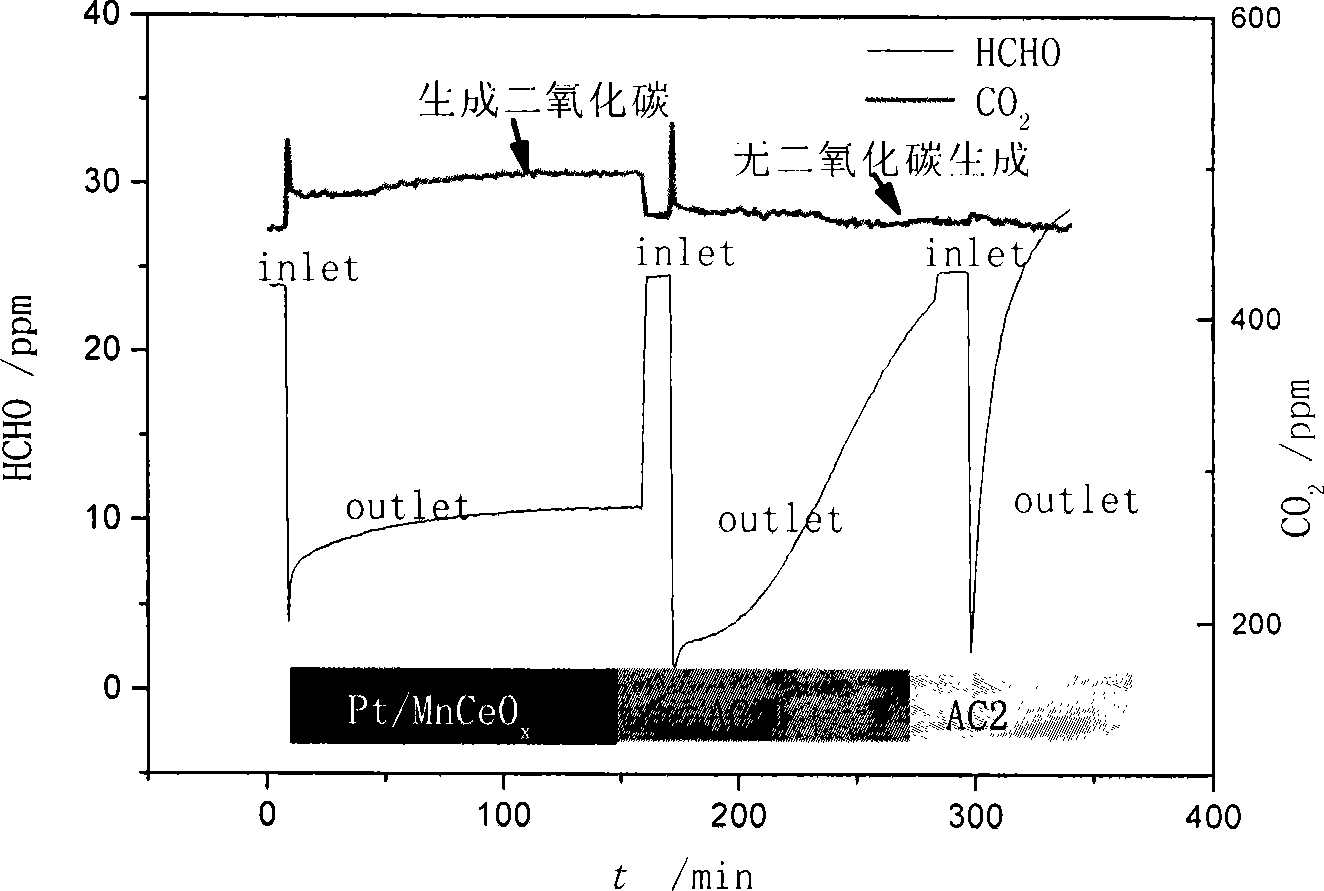

[0024] 0.3g Pt / MnCeOx was placed in a quartz fixed catalytic reaction bed to evaluate the catalytic oxidation activity of formaldehyde at room temperature. The reaction temperature is 22°C, the relative humidity is 60%, the air flow rate is 3L / min, and the equivalent space velocity is about 400,000h -1 . At the same time, ordinary activated carbon (AC2) and expanded activated carbon (AC1) were used as comparison samples. Experimental results such as figure 2 shown. From figure 2 It can be seen that although activated carbon has a certain ability to eliminate formaldehyde, it mainly relies ...

Embodiment 3

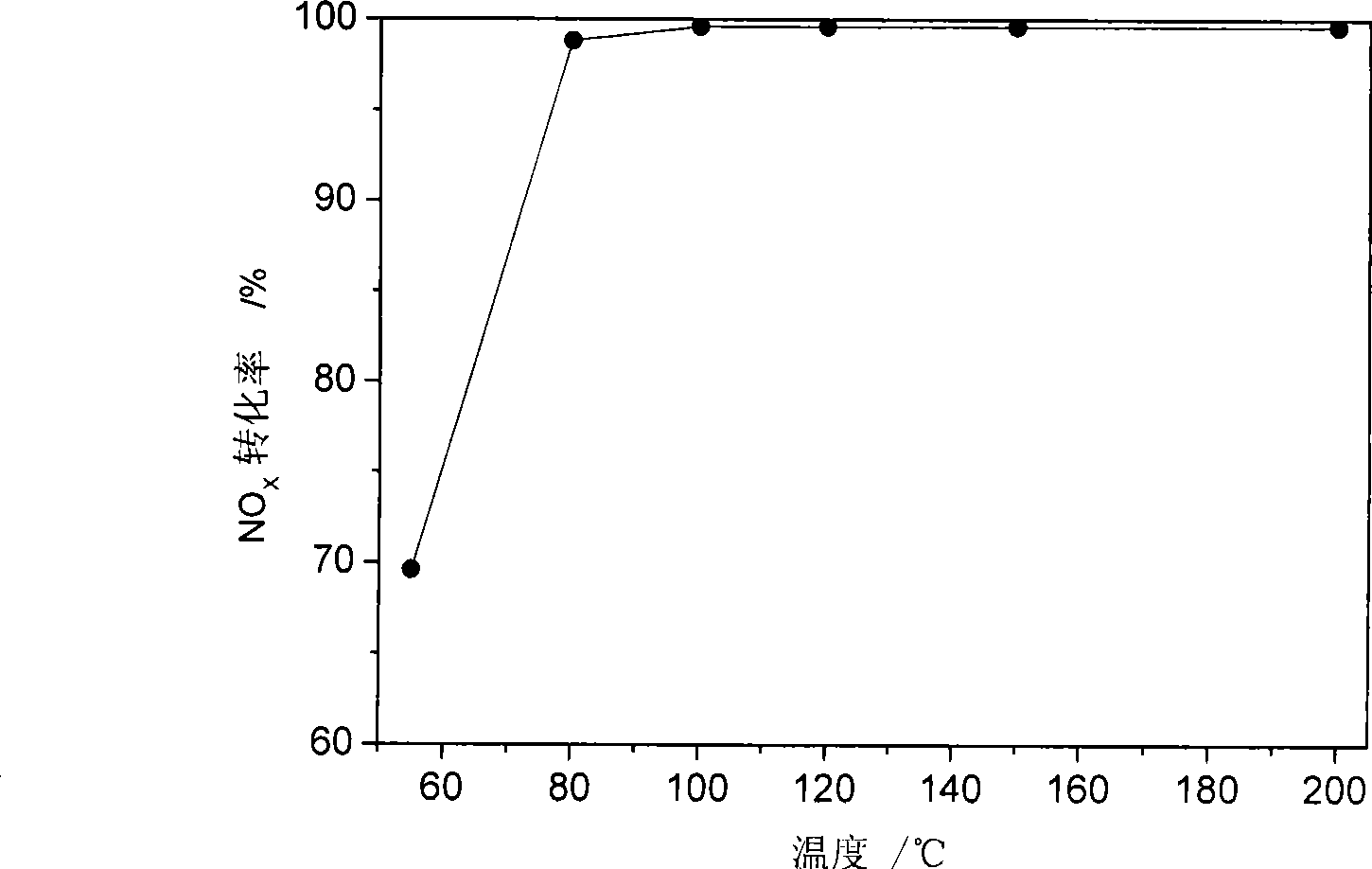

[0026] According to the steps in Example 1, a manganese-cerium composite oxide with a manganese-cerium ratio of 3:1 was prepared. Take 0.3g MnCeOx and place it in a quartz fixed catalytic reaction bed for low temperature NH 3 Selective catalytic reduction of NOx(NH 3 -SCR) activity assessment. The reaction temperature is 50℃~200℃, NOx 500ppm, NH 3 500ppm, O 2 8%, H 2 O 5%, SO 2 0.1ppm, air speed 50,000h -1 . Experimental results such as image 3 shown. From image 3 It can be seen that the effect of MnCeOx on NH 3 -SCR has good low temperature activity. A NOx conversion rate of more than 70% can be achieved at around 60°C, and nearly 100% of NOx can be converted into N at a temperature above 80°C. 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com