Method for preparing crystalline silicon solar cell with passivation on double surfaces

A solar cell and double-sided passivation technology, which is applied in the field of solar photovoltaic utilization, can solve the problems of large-scale, low-cost industrial production of solar cells, and high price, so as to be suitable for large-scale production, improve conversion efficiency, reduce small bend effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

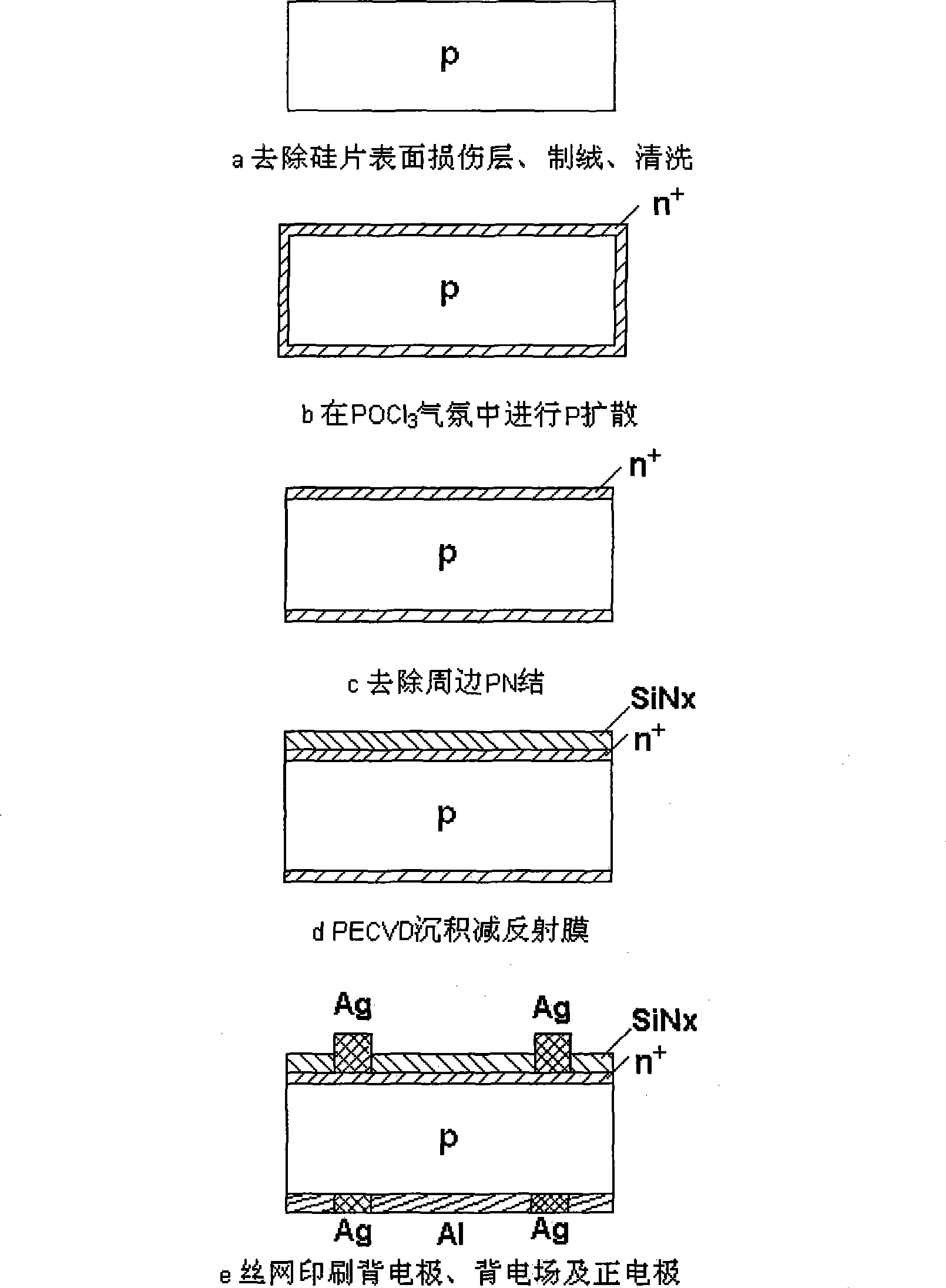

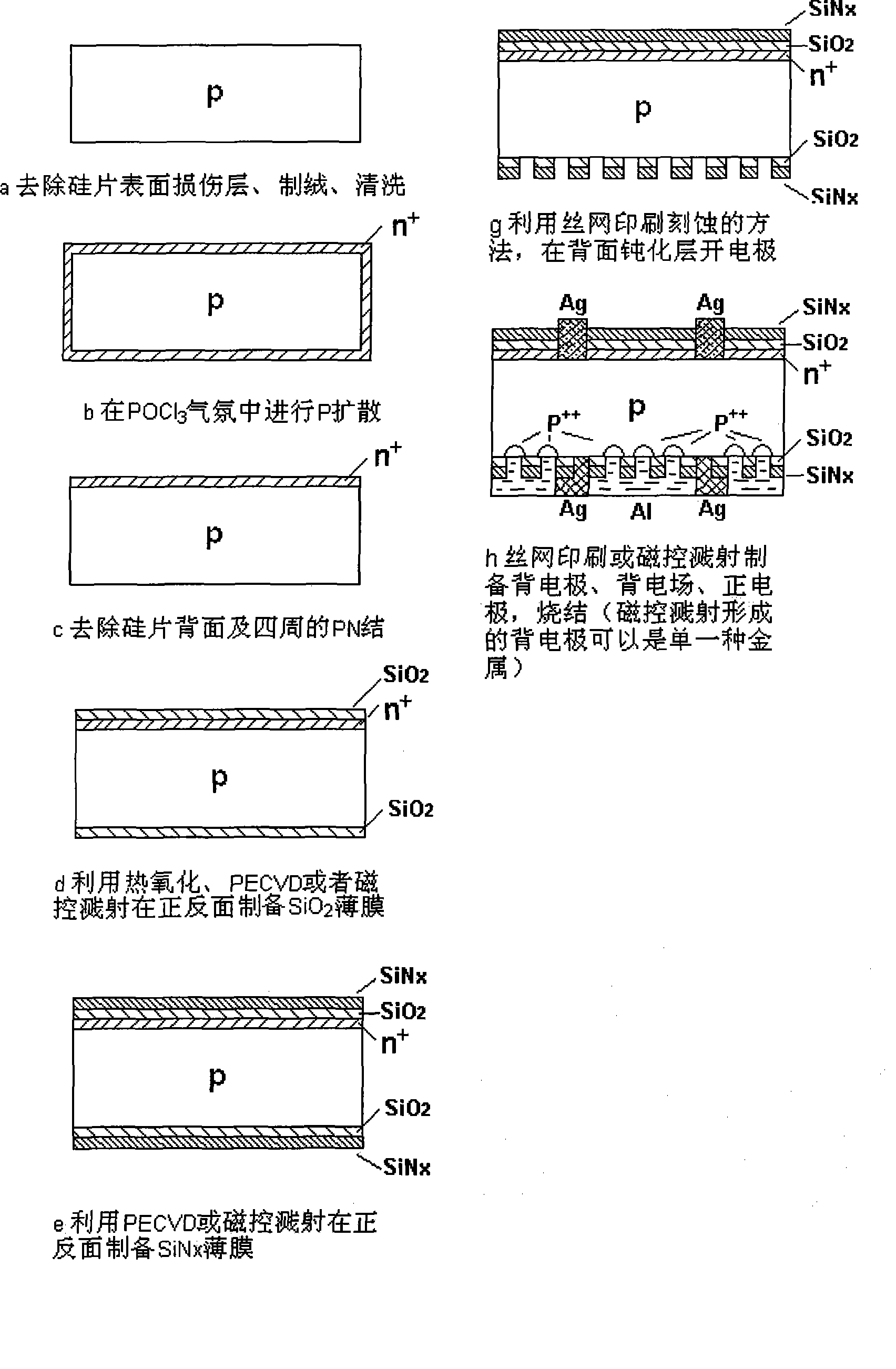

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. figure 2 Shown is the specific preparation process of the double-sided passivated crystalline silicon solar cell of the embodiment of the present invention:

[0031] (1) Remove the damaged layer and the textured surface of the silicon wafer surface;

[0032] (2) Diffusion of P in POCl3 atmosphere to form n + diffusion layer;

[0033] (3) Use wet etching to remove the PN junction on the back of the silicon wafer and the surrounding area (the traditional process only needs to remove the PN junction around the silicon wafer after diffusion, and the PN junction on the back side will be removed during the process of making the back electric field. A1 is compensated, but in the process of preparing double-sided passivated solar cells, since the aluminum paste printed on the back will be separated by the laminated passivation layer, it cannot compensate for t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com